Splash guard for a floor cleaning machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

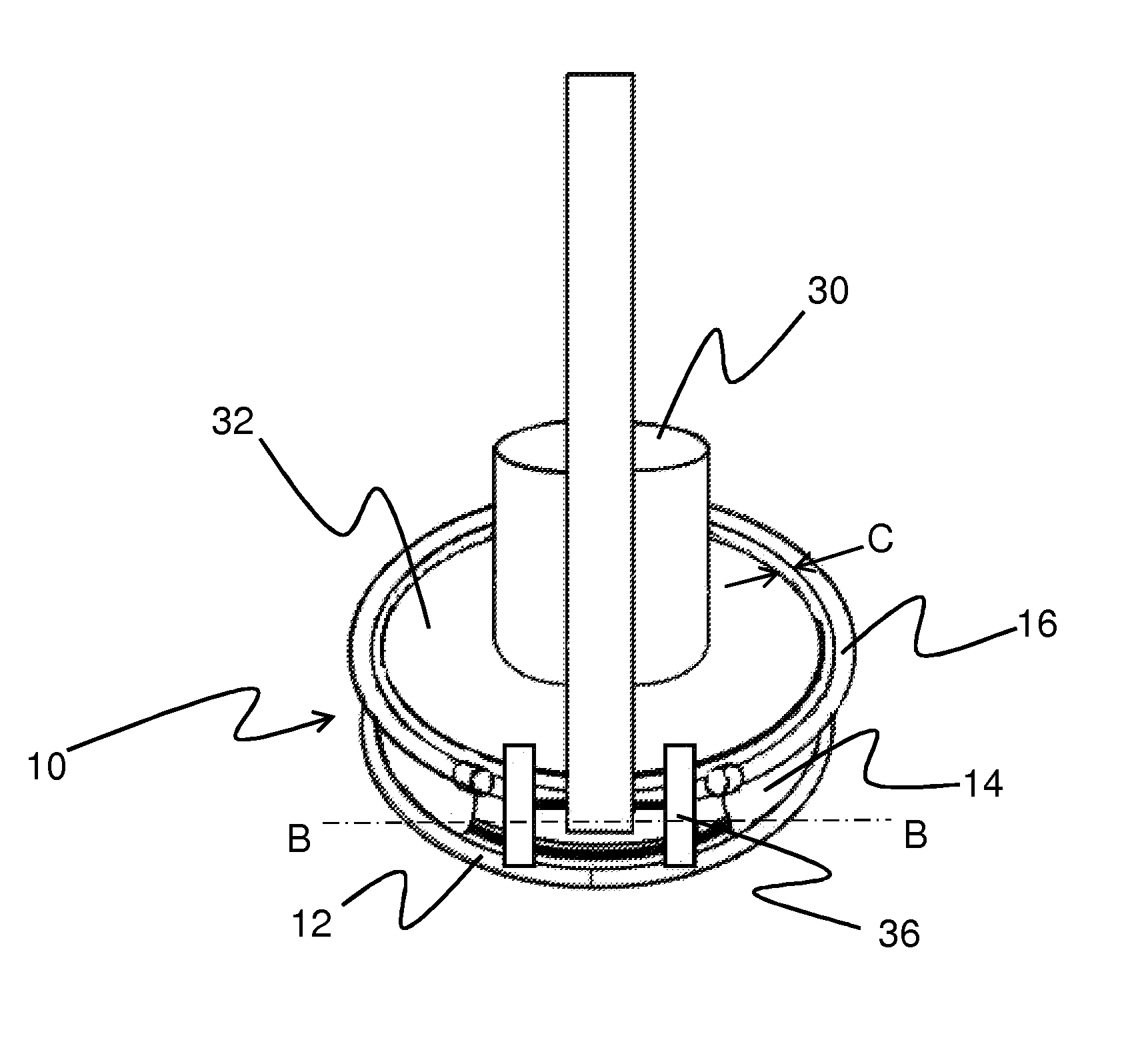

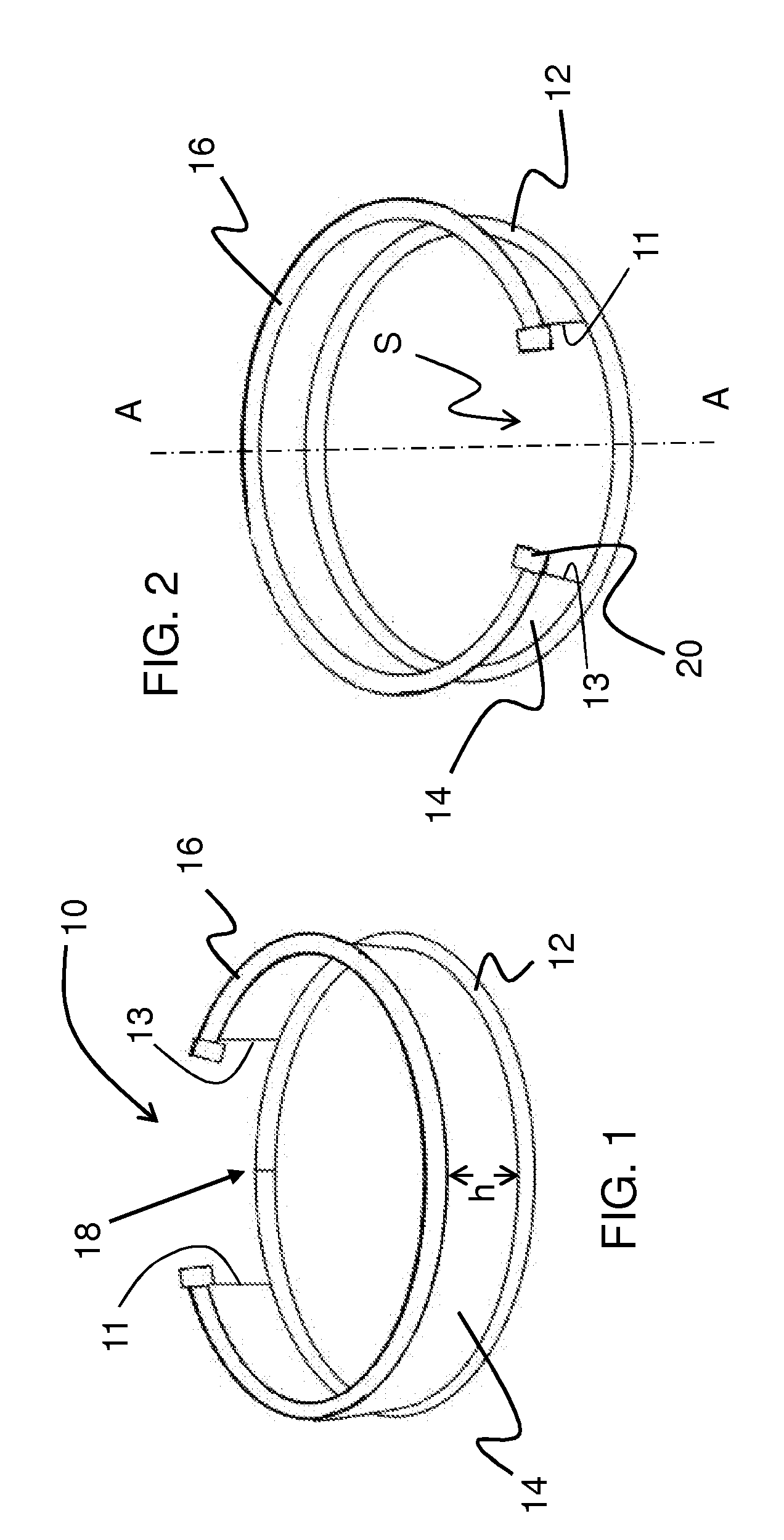

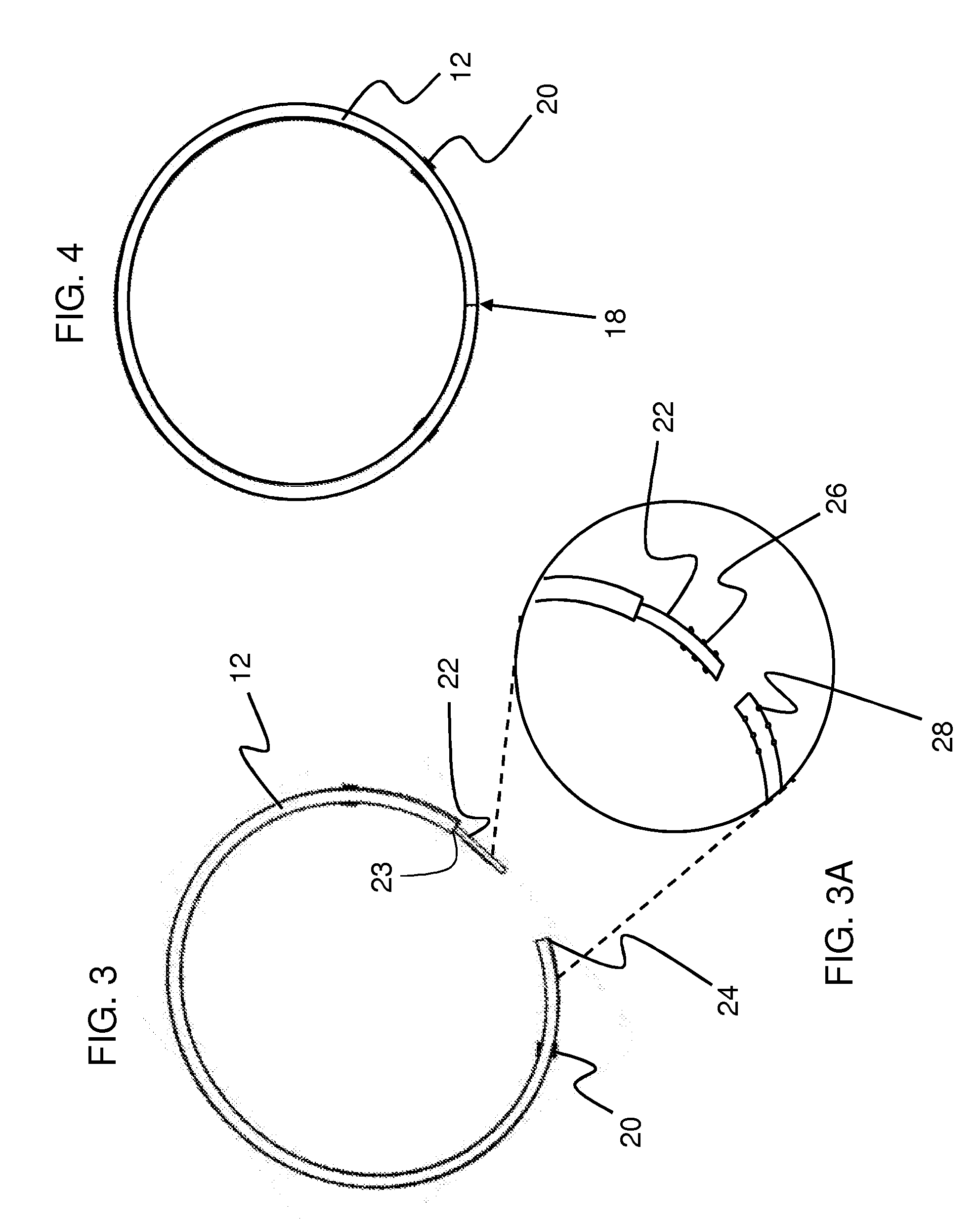

[0025]A front view of the splash guard apparatus 10 is shown in FIG. 1 and consists of a circumferential lower bumper 12, a pliable housing 14, and a partially circumferentially encompassing upper tubular bumper 16. The pliable housing 14 is attached to and substantially around a portion of the ring that is formed when the lower bumper 12 is connected at the quick connection point 18. The pliable housing 14 is made from a material flexible enough to bend in a radial manner around a central axis A, but rigid enough so that the housing 14 does not bend or collapse in an axial manner relative to axis A. The axial height h of the housing may be from 1-10 inches but is preferably about 3-6. The upper tubular bumper 16 may attach to the full length of the pliable housing 14 or may extend ½″ to 1½″ past the ends of the housing 14 in order to attach bumper caps 20 that enclose the tubular bumper ends for protection from scraping or gouging by the tubular ends.

[0026]The rear view of the spla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com