System for semiconductor structure processing using multiple laser beam spots

a laser beam spot and semiconductor technology, applied in the direction of semiconductor/solid-state device details, manufacturing tools, metal working apparatuses, etc., can solve the problems of difficult to achieve large throughput gains, link banks may not be straight rows, link runs may not be processed with continuous motion, etc., to achieve high degree of closeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

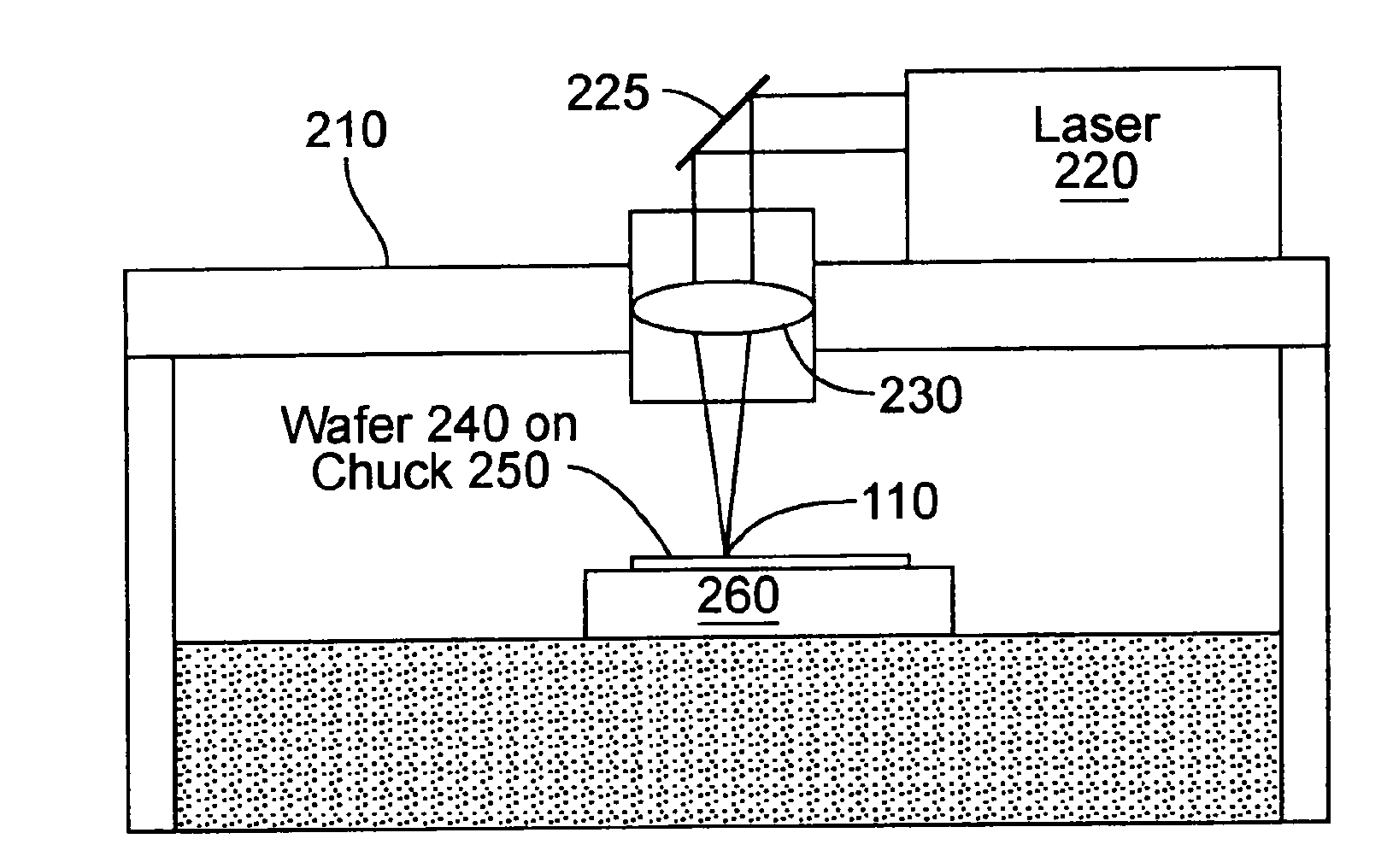

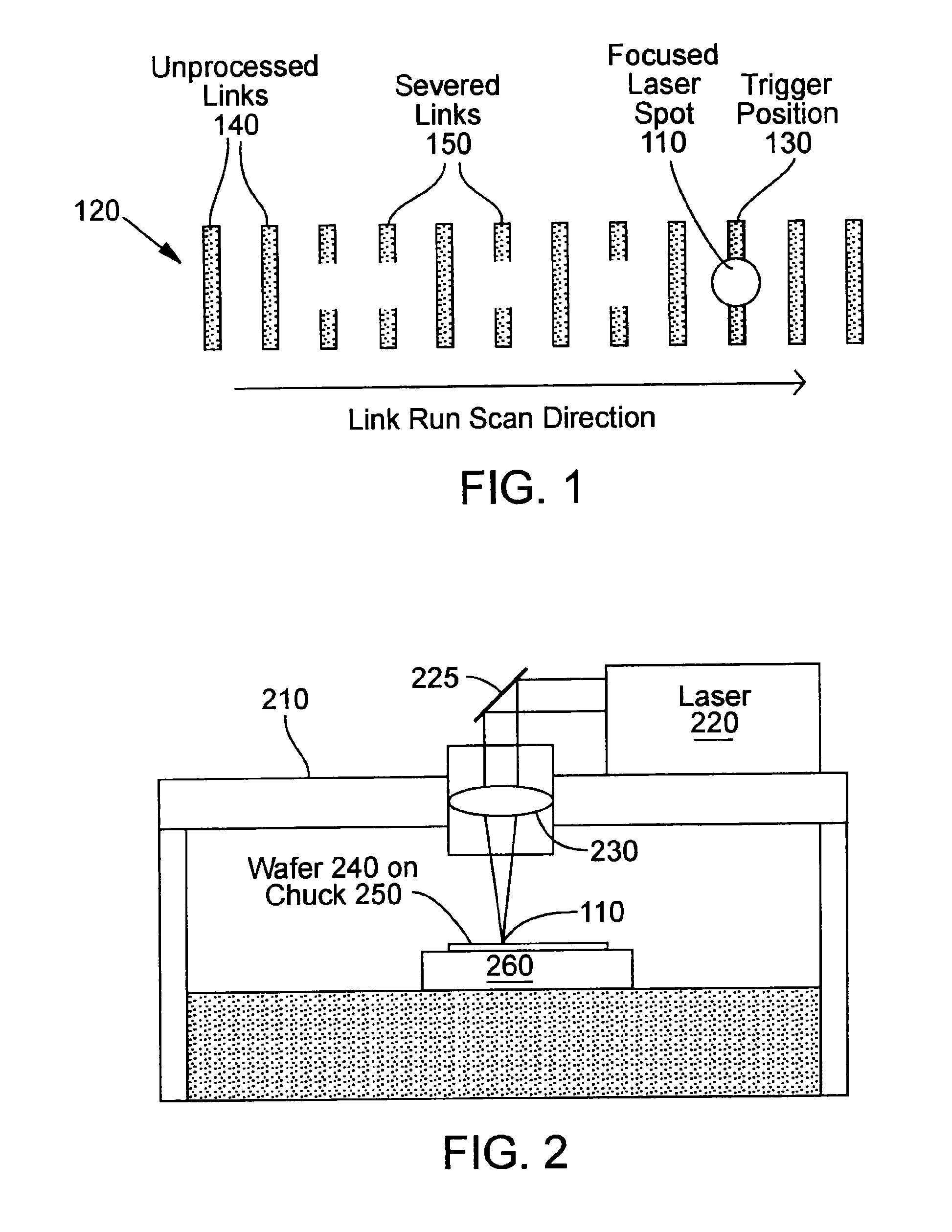

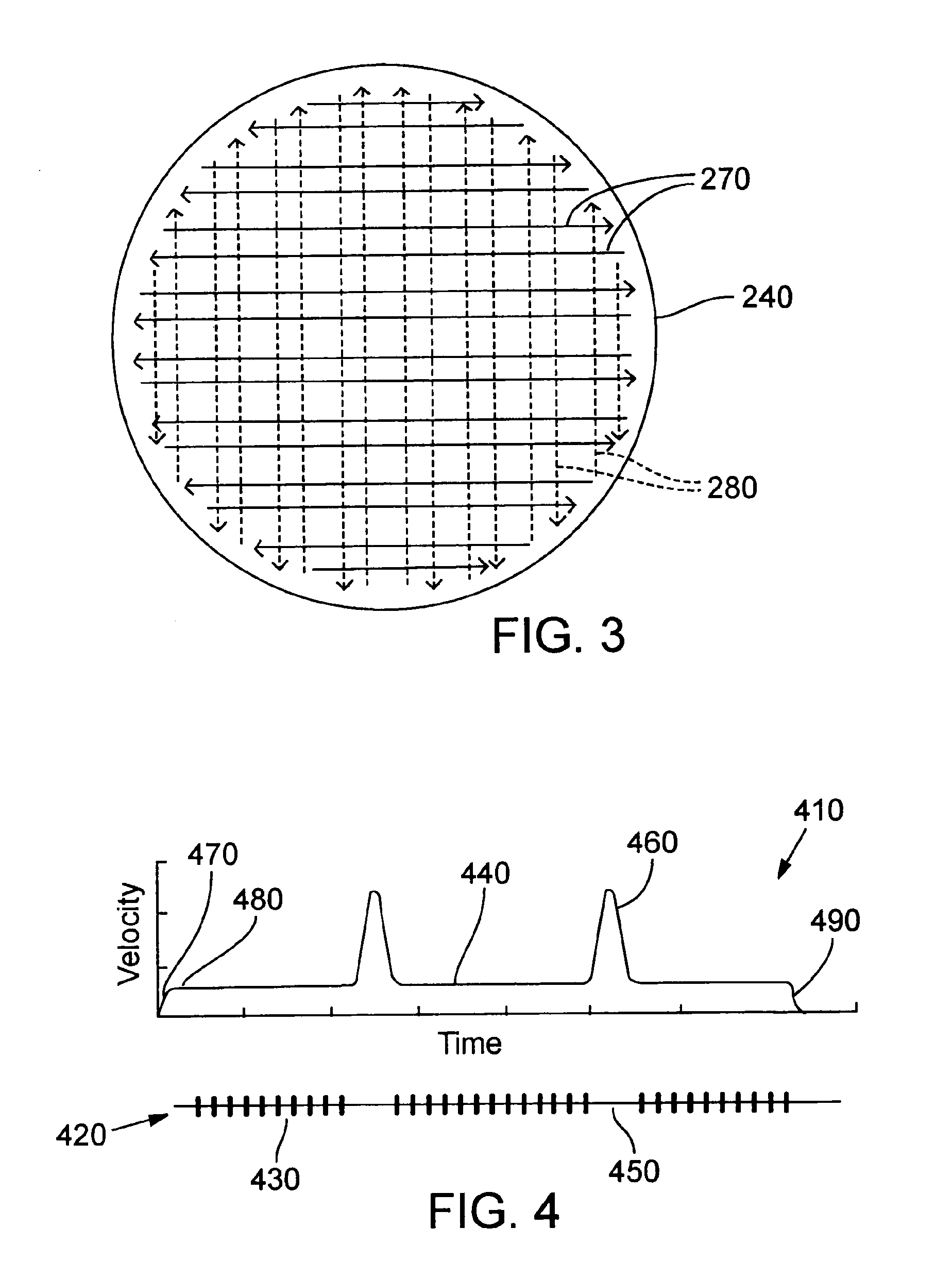

With reference to the above-listed drawings, this section describes particular embodiments and their detailed construction and operation. The principles, methods, and systems disclosed below have general applicability for processing any structure on or within a semiconductor substrate using laser radiation for any purpose. While the examples and embodiments that follow are described in the context in which those structures are laser-severable links on or within an IC (e.g., memory device, logic device, optical or optoelectronic device including LEDs, and microwave or RF devices), other structures besides laser-severable links can be processed in the same or similar manner, and the teachings set forth herein are equally applicable to the laser processing of other types of structures, such as electrical structures that become conductive as a result of laser radiation, other electrical structures, optical or electro-optical structures, and mechanical or electro-mechanical structures (e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com