Single-crystal manufacturing method and single-crystal manufacturing apparatus

a manufacturing method and single crystal technology, applied in the field of single crystal manufacturing, can solve the problems of reducing the yield ratio of silicon single crystal, affecting the quality of manufactured single crystal, and the inability to manufacture silicon single crystal in conformity with a demanded quality standard, etc., and achieve the effect of suppressing the fluctuations in diameter and oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

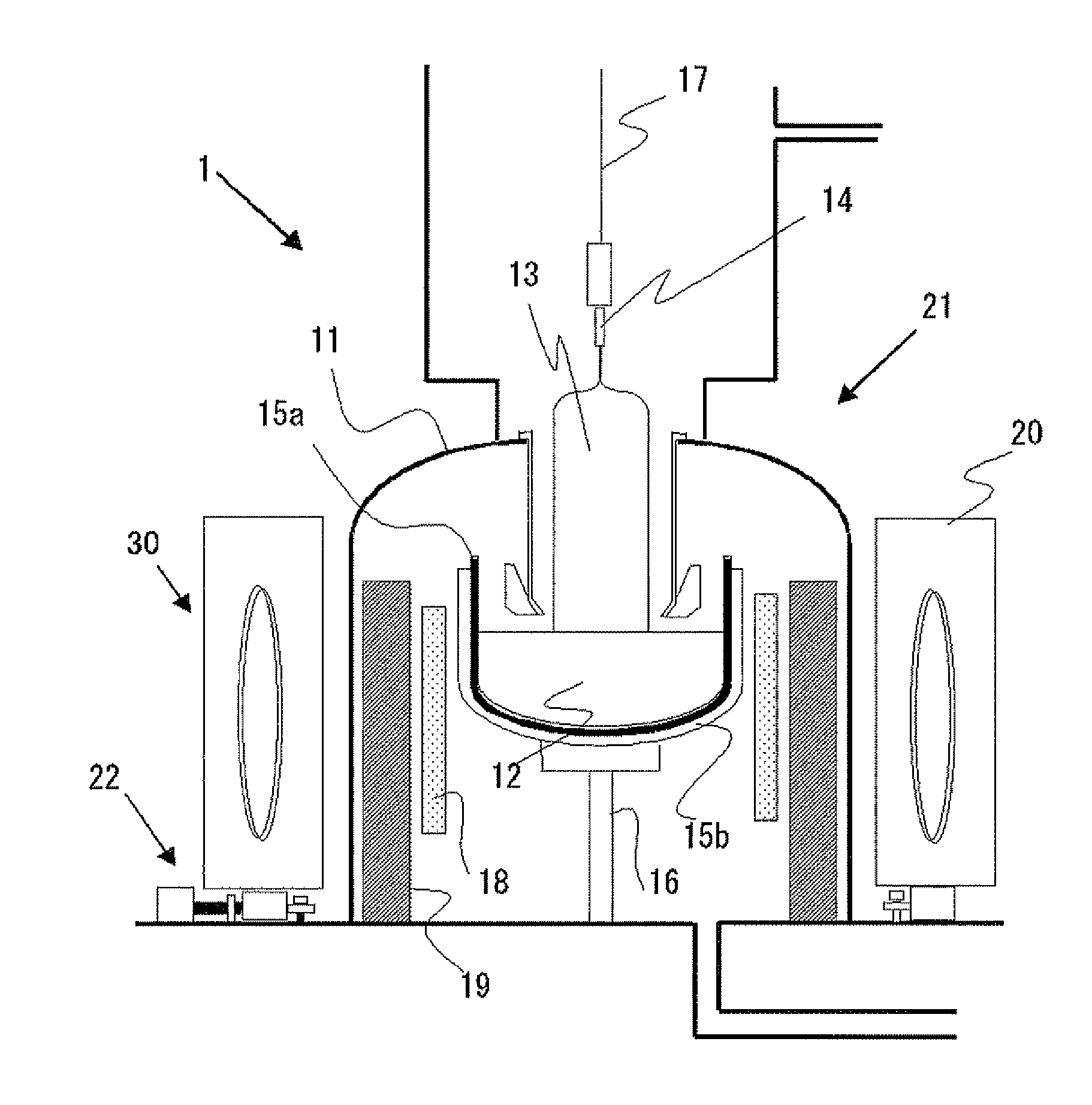

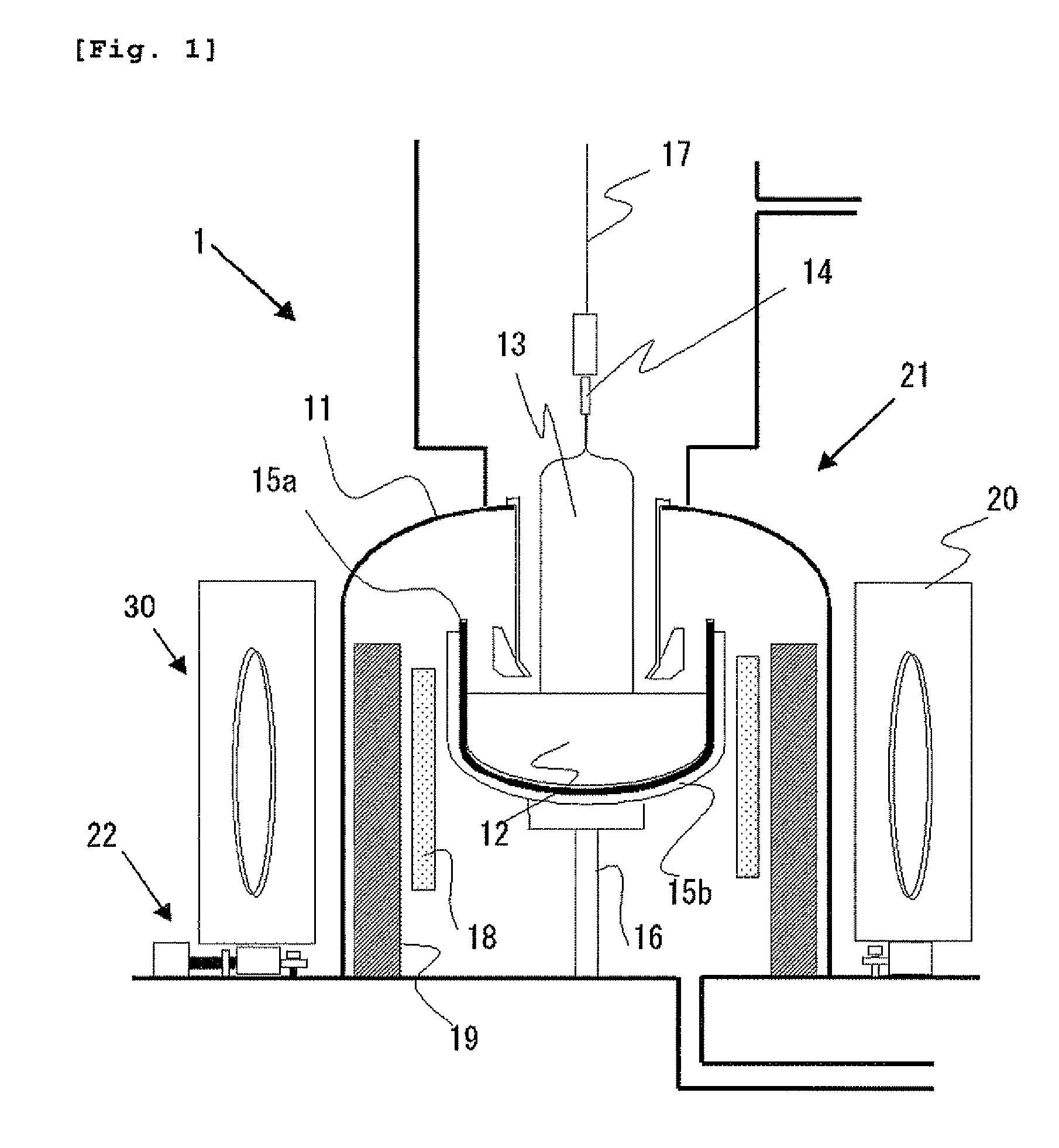

[0069]The manufacturing apparatus shown in FIG. 1 was utilized to manufacture a silicon single crystal having a diameter of 8 inches (200 mm) from a silicon melt of 200 kg. An intensity of a magnetic field generated from a magnetic field application device was set to 4000 gauss (0.4 T).

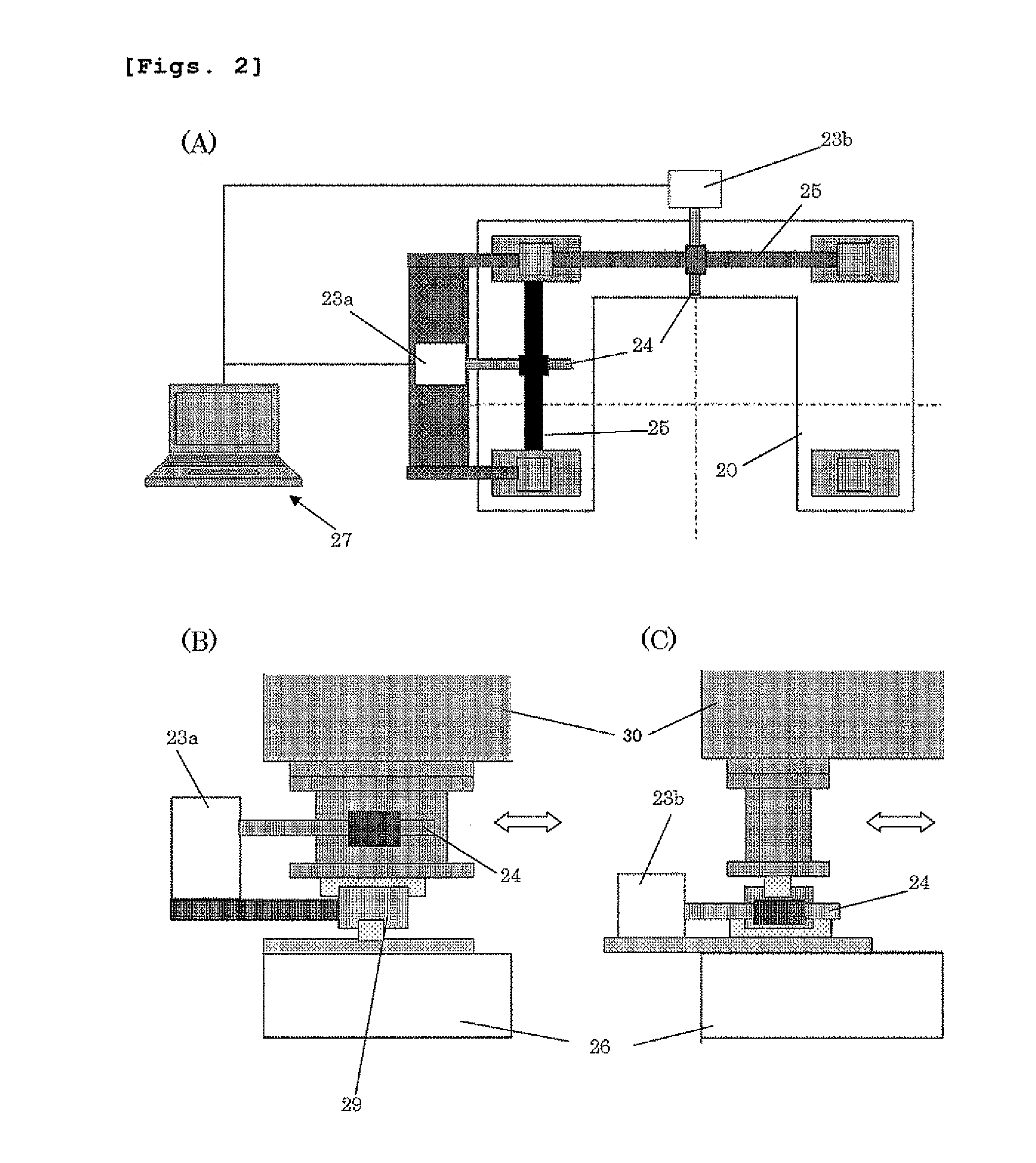

[0070]At this time, a center position of the magnetic field generated from the magnetic field application device was measured in advance as described above. Additionally, to set movement conditions for the magnetic field application device, a center position of the magnetic field on an initial stage after installation of the device was measured in advance, and the magnetic field application device was moved in the range of 2 to 14 mm to confirm a deviation position that is effective for suppression of a fluctuation in diameter and a fluctuation in oxygen concentration.

[0071]Then, the measured magnetic field center and a pulling member were deviated from a state, in which they were deviated 5 mm in an ...

example 2

[0073]The apparatus shown in FIG. 1 was utilized to manufacture a silicon single crystal having a diameter of 8 inches (200 mm) from a silicon melt of 200 kg. An intensity of a magnetic field generated from a magnetic field application device was set to 4000 gauss (0.4 T).

[0074]At this time, a center position of the magnetic field generated from the magnetic field application device was measured in advance as described above. Furthermore, the measured magnetic center and a pulling member were fixed to a state that they were deviated 5 mm in the X (left-and-right) direction before manufacture of the single crystal to manufacture the single crystal.

[0075]Further, a single crystal was manufactured in the same way as the above description except for setting the deviating direction to a Y (front-and-back) direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com