Method for Operating a Reducing Agent Supply System

a technology of reducing agent and supply system, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve the problems of unwanted expense, malfunctions, and the provision of third medium, so as to reduce the cross-section of the line system, increase the resistance to flow, and achieve the effect of measurable pressure increas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

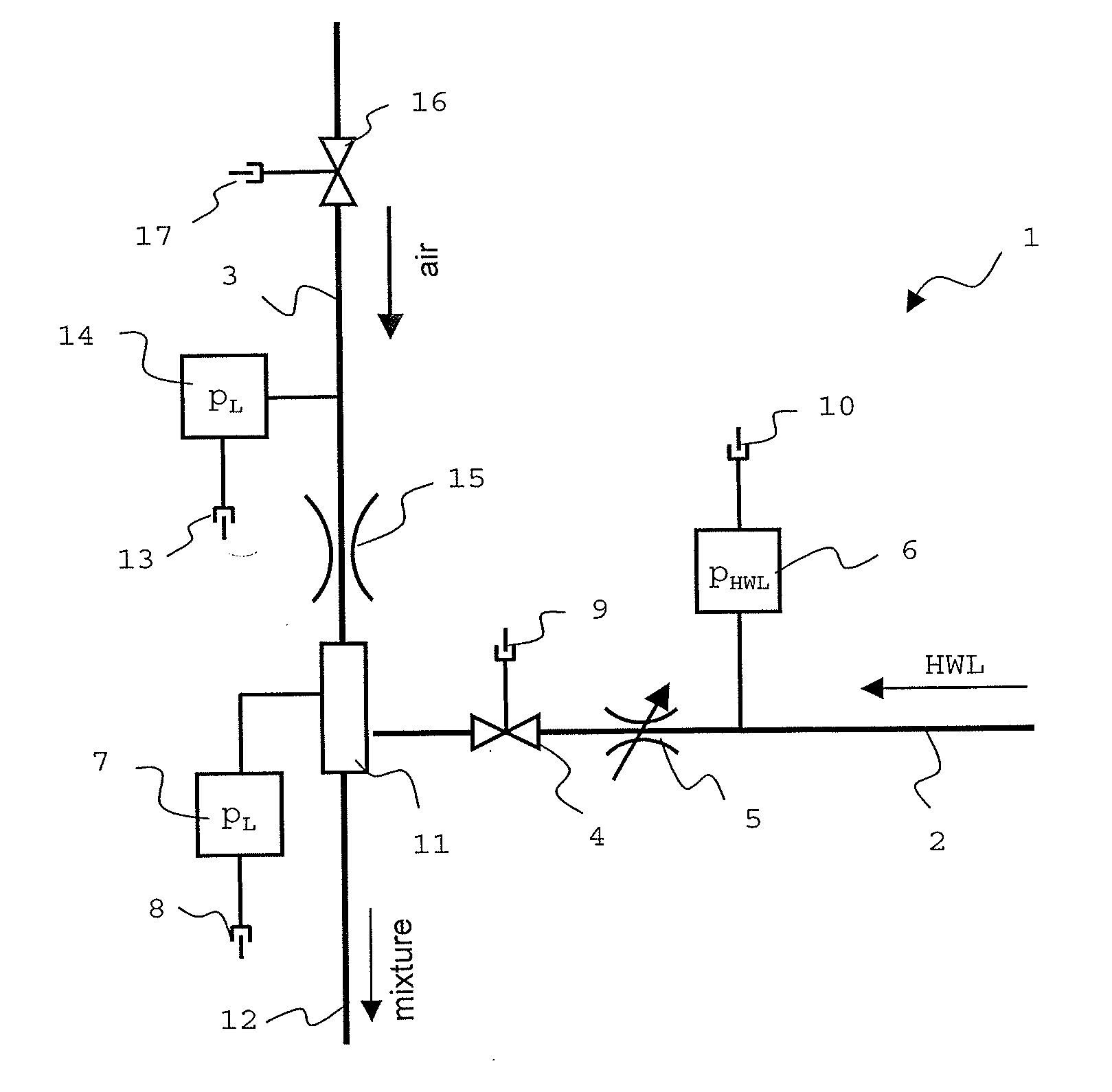

[0019]In the advantageous embodiment diagrammatically illustrated in FIG. 1, a reducing agent supply system 1 comprises a liquid supply line 2 for a liquid that is to be metered. A metering valve 4, which can be operated in timed manner, and an adjustable adjusting choke 5, a first pressure sensor 6 are arranged in the liquid supply line 2. The liquid supply line 2 opens, as does an air supply line 3 for supplying compressed air, into a mixing region 11 of the reducing agent supply system 1. In the mixing region 11, thorough mixing of supplied compressed air and liquid takes place such that an aerosol-like mixture with liquid droplets are produced that are as small as possible. The mixing region 11 may be formed as a separate mixing chamber or as an integral component of the liquid supply line 2 or the air supply line 3.

[0020]Below, it will be assumed that the liquid is an aqueous urea solution (HWL), which can be sprayed in the form of the aerosol-like mixture by means of a nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com