Separation Vessels For Use In Polymerization Processes And Methods For Cleaning Same

a separation vessel and polymerization process technology, applied in the direction of cleaning hollow articles, chemical/physical/physical-chemical processes, chemistry apparatus and processes, etc., can solve the problems of reducing the cleaning efficiency of the separation vessel, affecting the cleaning effect, and affecting the appearance and film properties of the final polyethylene product, so as to achieve a more thorough cleaning, reduce the number of vessel cleanings, and promote a higher degree of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

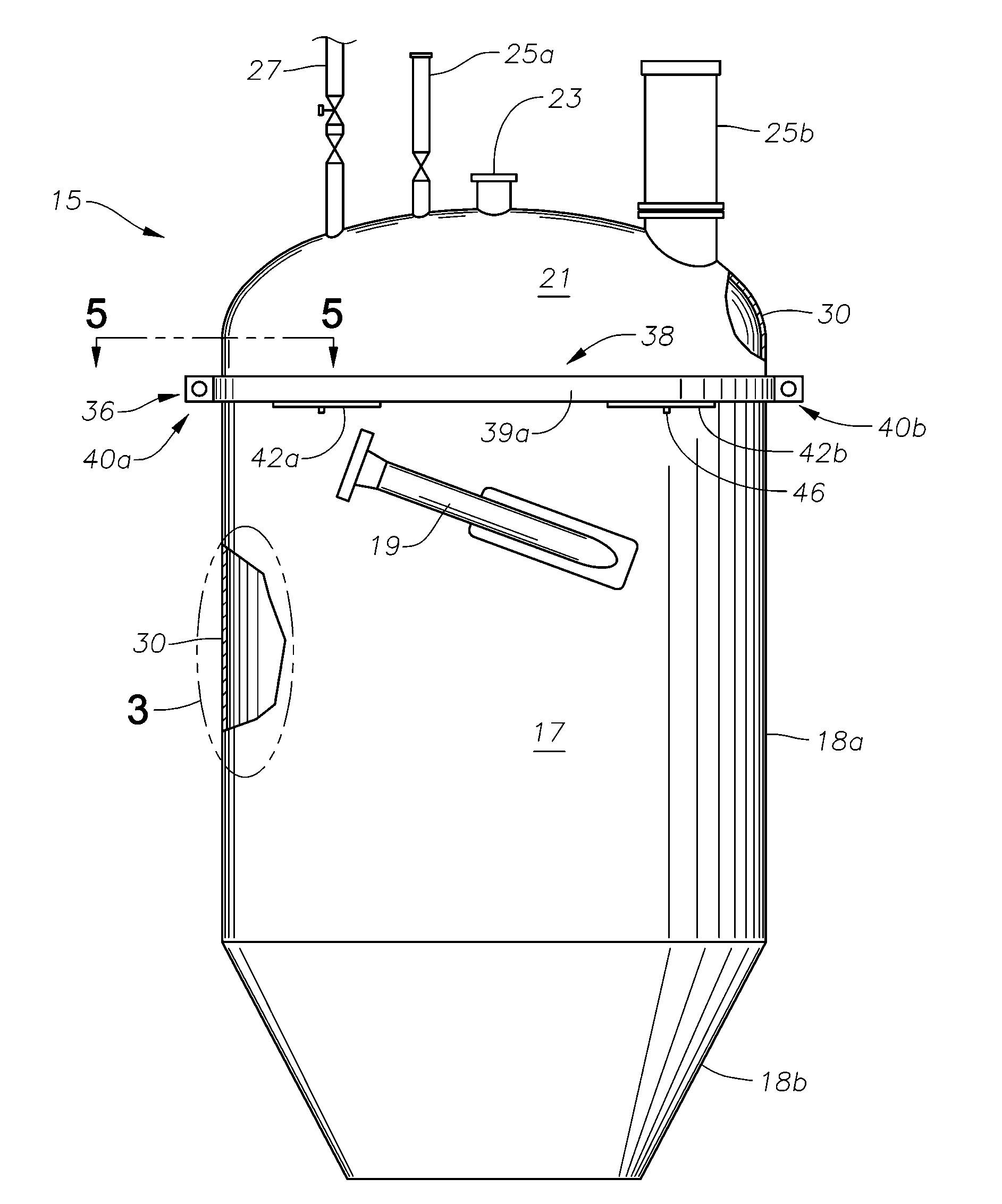

[0021]FIG. 1 is a schematic of a polymerization plant 1 of the type that includes the low pressure separator vessel 15 that the cleaning system and method are applied to. The low pressure separator vessel typically operates at a pressure in the range of from 0.1 to 20 barg, more preferably from 0.1 to 5 barg, yet more preferably from 0.1 to 2 barg and especially preferably from 0.1 to 0.9 barg (barg=bar gauge, that is, pressure in excess of atmospheric). The plant 1 includes an ethylene feed line 2 which supplies fresh ethylene to a primary compressor 3. The ethylene discharged from the primary compressor 3 flows via conduit 4 having a valve 4a to a secondary compressor 5. Also entering the secondary compressor 5 is a stream of fresh modifier(s) and / or optional comonomer(s) and a stream of recycled ethylene. The fresh modifier stream is supplied by a separate modifier pump 6. The recycled ethylene comes from the high pressure recycle system 7.

[0022]The secondary compressor 5 dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com