Method for Adjusting Metal Polishing Rate and Reducing Defects Arisen in a Polishing Process

a technology of metal polishing rate and polishing process, which is applied in the direction of grinding machines, manufacturing tools, lapping machines, etc., can solve the problems of increasing the demand for non-uniformity of the wafer surface, reducing the productivity of lithographs, and reducing the cost. , to achieve the effect of reducing the defects of dishing and erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Hereinafter, the embodiments of the invention will be described in detail with reference to the appended drawings.

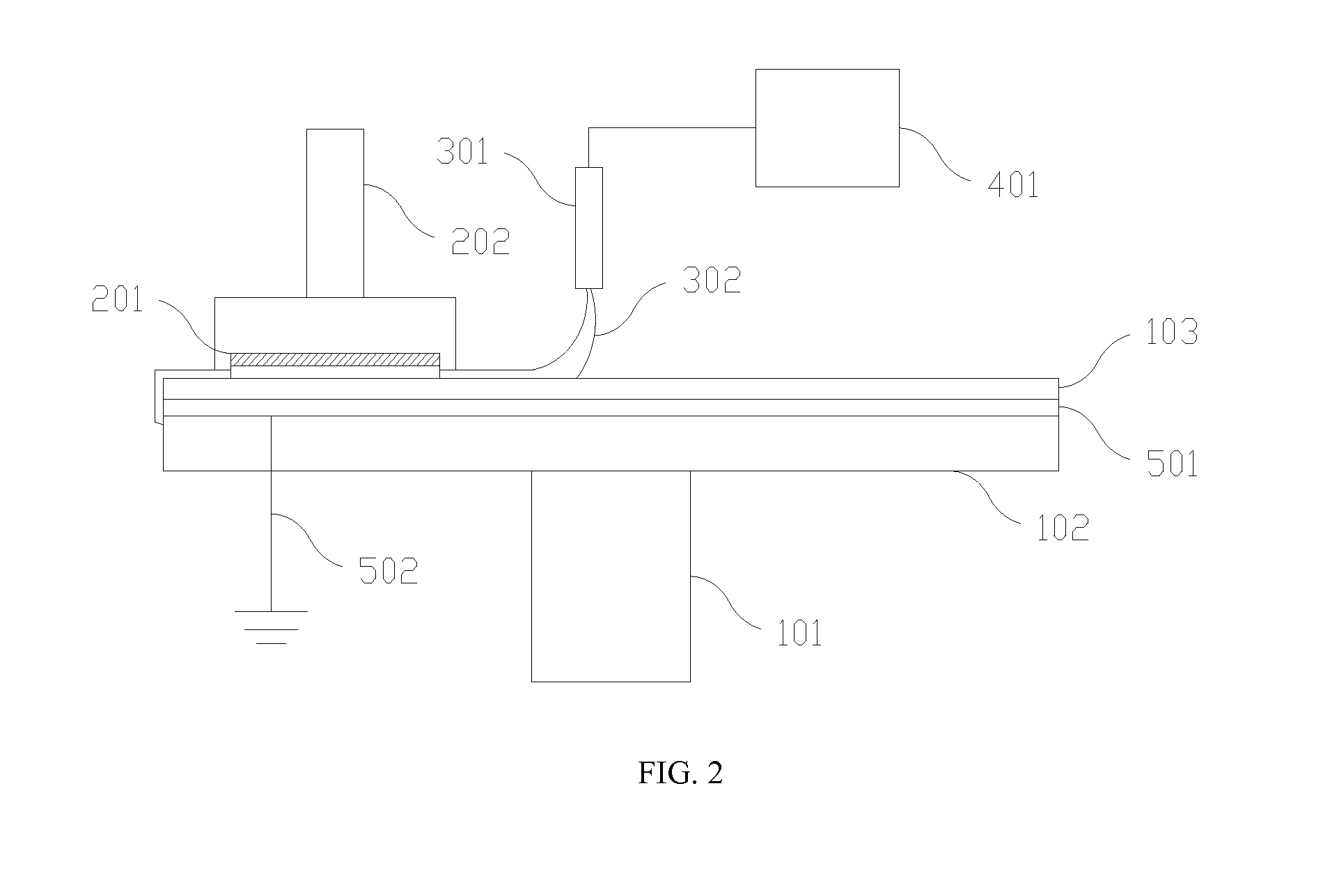

[0028]FIG. 2 is a schematic structural diagram of an apparatus for adjusting a metal polishing rate and reducing defects arisen in a polishing process according to the invention. Refer to FIG. 2, a method for adjusting a metal polishing rate and reducing defects arisen in a polishing process according to the invention may comprise a step of adding an electric conduction system 401 to the polishing apparatus. The electric conduction system 401 provides an additional current and electrical field, and is connected to a polishing fluid outlet 301 of a polishing stand of the polishing apparatus in order to electrify a polishing fluid 302 from the outlet 301. In the polishing process, the polishing fluid 302 flows down from the polishing fluid outlet 301, and flows through a polishing pad 103; a wafer 201 is mounted on a wafer bracket 202, and a surface of the wafer 201 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com