Tunnel typed coking furnace with a movable sliding bed and the method using the same

a coking furnace and tunnel-type technology, applied in the direction of horizontal chamber coke ovens, furnaces, lighting and heating apparatus, etc., can solve the problems of high raw material cost, long furnaces, and high cost of coal gas, and achieve high product quality, reasonable structure, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

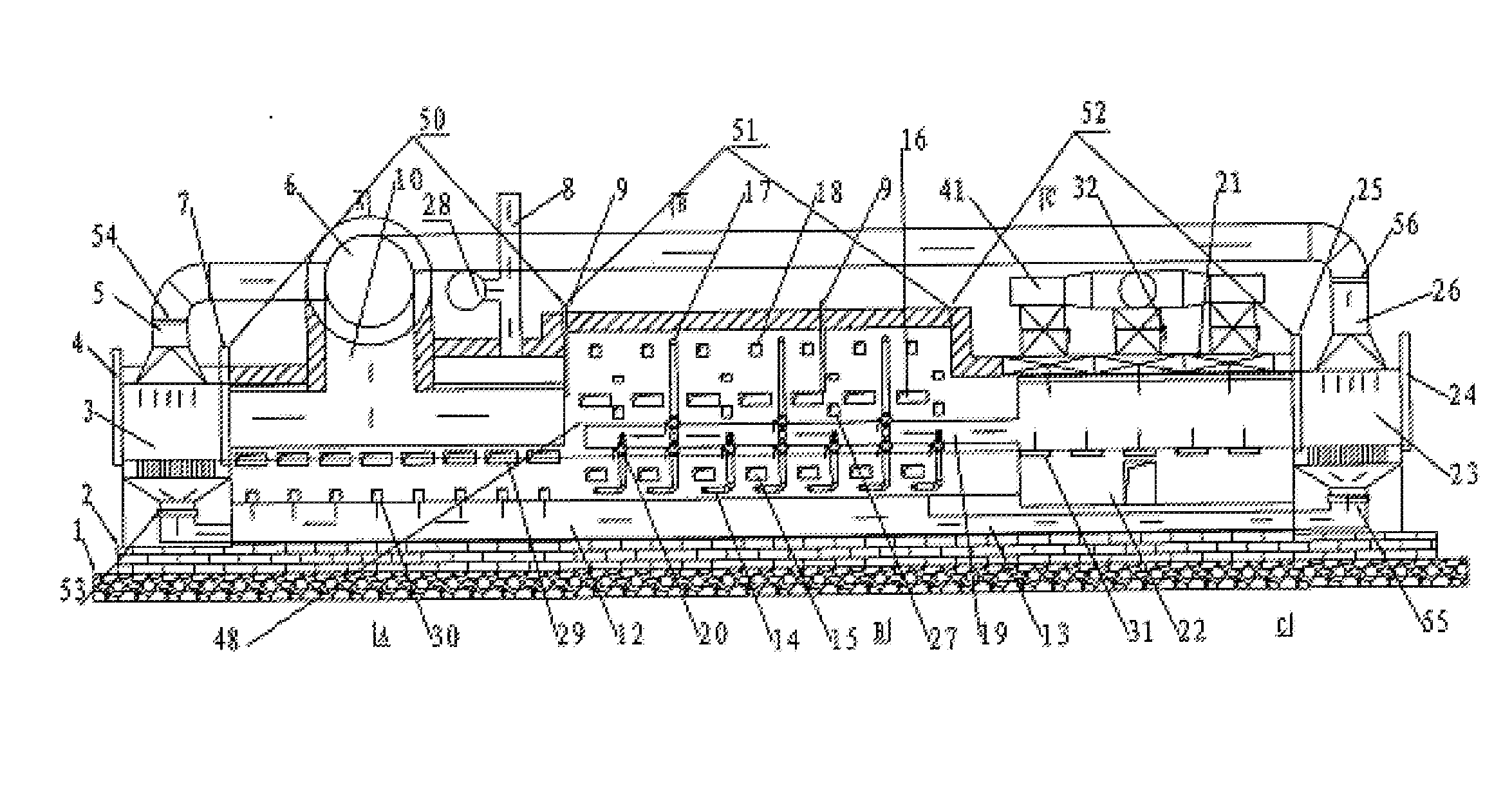

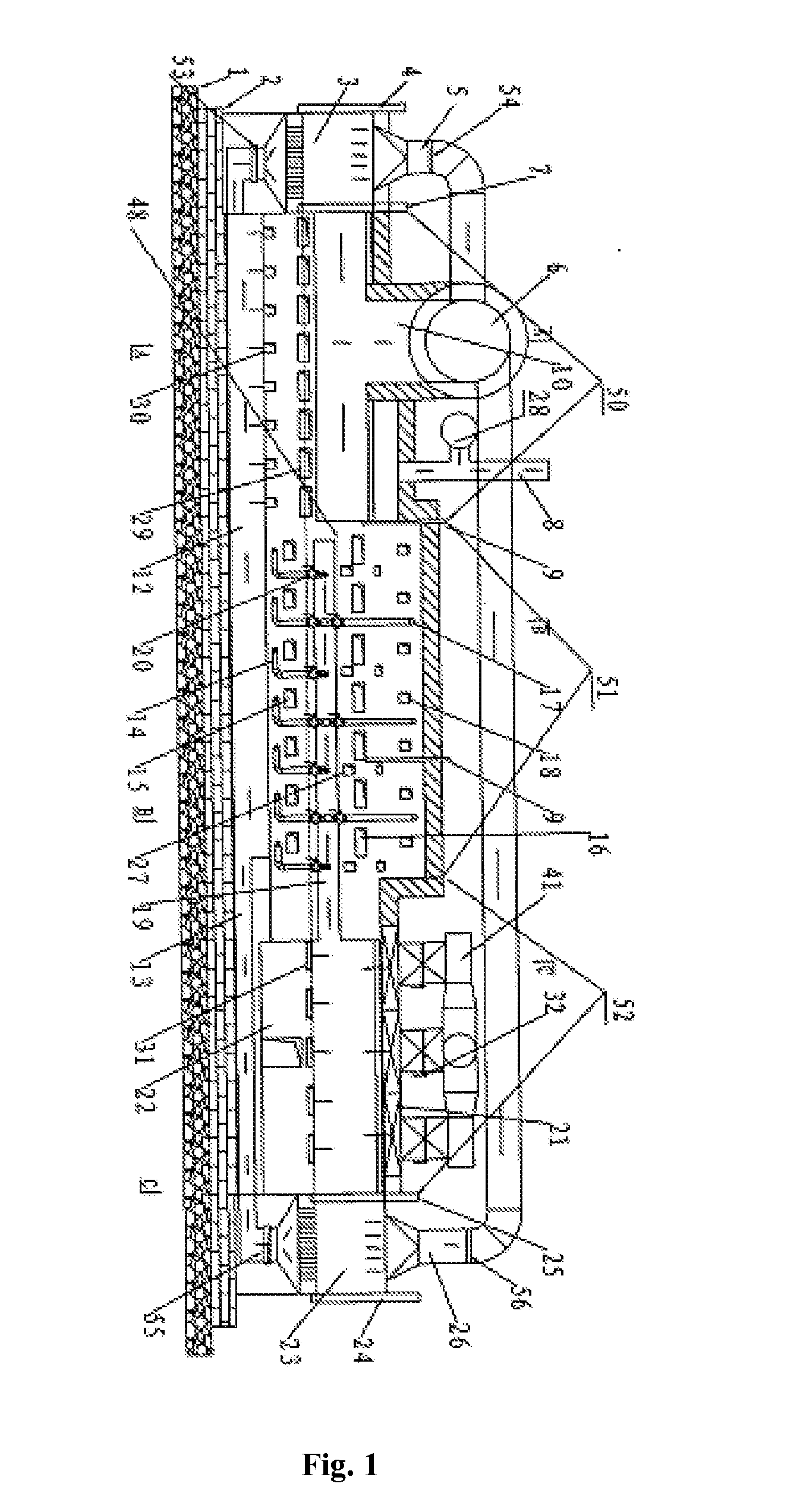

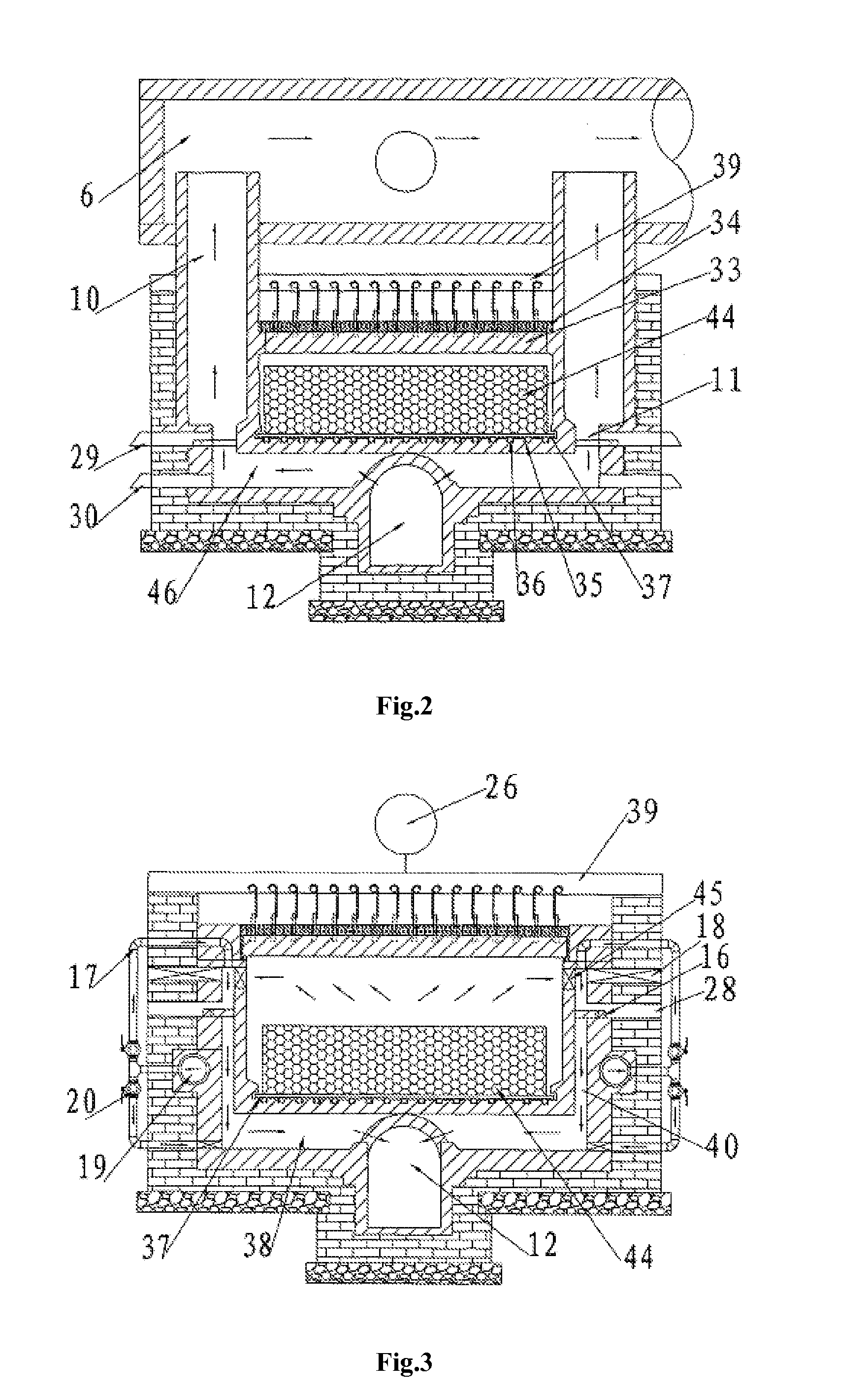

[0034]There are specific modes for carrying out the invention with the drawings (FIG. 1 to FIG. 4)

[0035]A tunnel typed coking furnace, comprising a furnace top 33, a first insulating layer 34 formed at the furnace top 33, a ceiling beam 39, two side walls, a furnace body 48 formed by a furnace body base 1 and a furnace bottom constituted by a second insulating layer 2 formed at the bottom of the furnace, a front sealing door 7 of the furnace body, a back sealing door 25 of the furnace body, a branch flue 10, a bottom flue 12, and a main flue 6, is characterized in that the tunnel typed coking furnace consists of a first preparation chamber 3 for coaling, a preheating segment 50, a carbonization segment 51, a coke dry quenching segment 52, and a second preparation chamber 23 for coke outlet, and each part has different formation from the others, and are interconnected in series with the others; and a plurality of individual bottom channels 38,46,47 are formed above the first insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tap density | aaaaa | aaaaa |

| areas | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com