Methods of consolidating radioactive containing materials by hot isostatic pressing

a radioactive material and isostatic pressing technology, applied in shaping presses, nuclear engineering, nuclear elements, etc., can solve the problems of reducing the maximum achievable waste loading efficiency and/or process flexibility, glass the waste stream cannot be designed solely to suit the waste stream, etc., to achieve the effect of reducing process tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

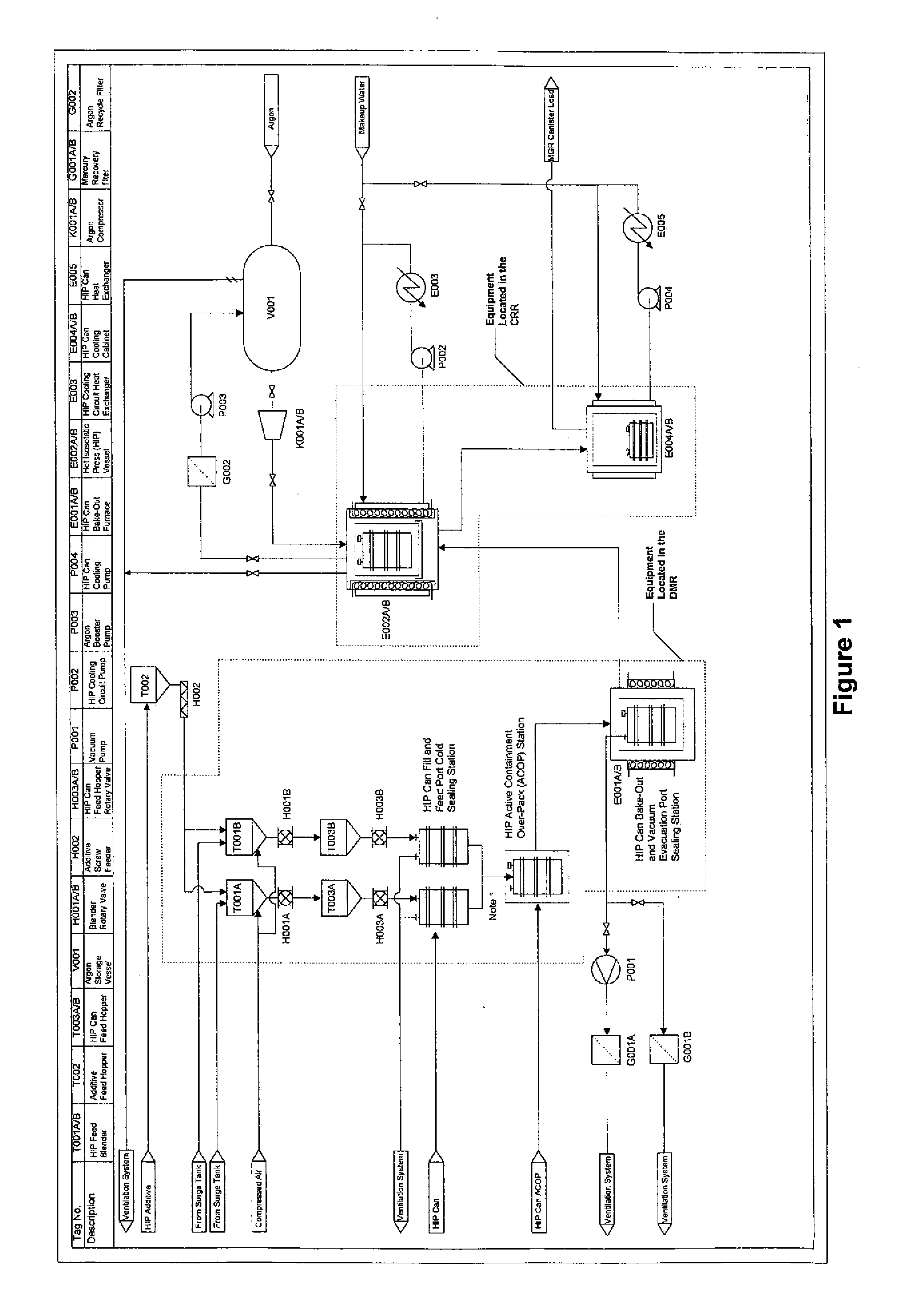

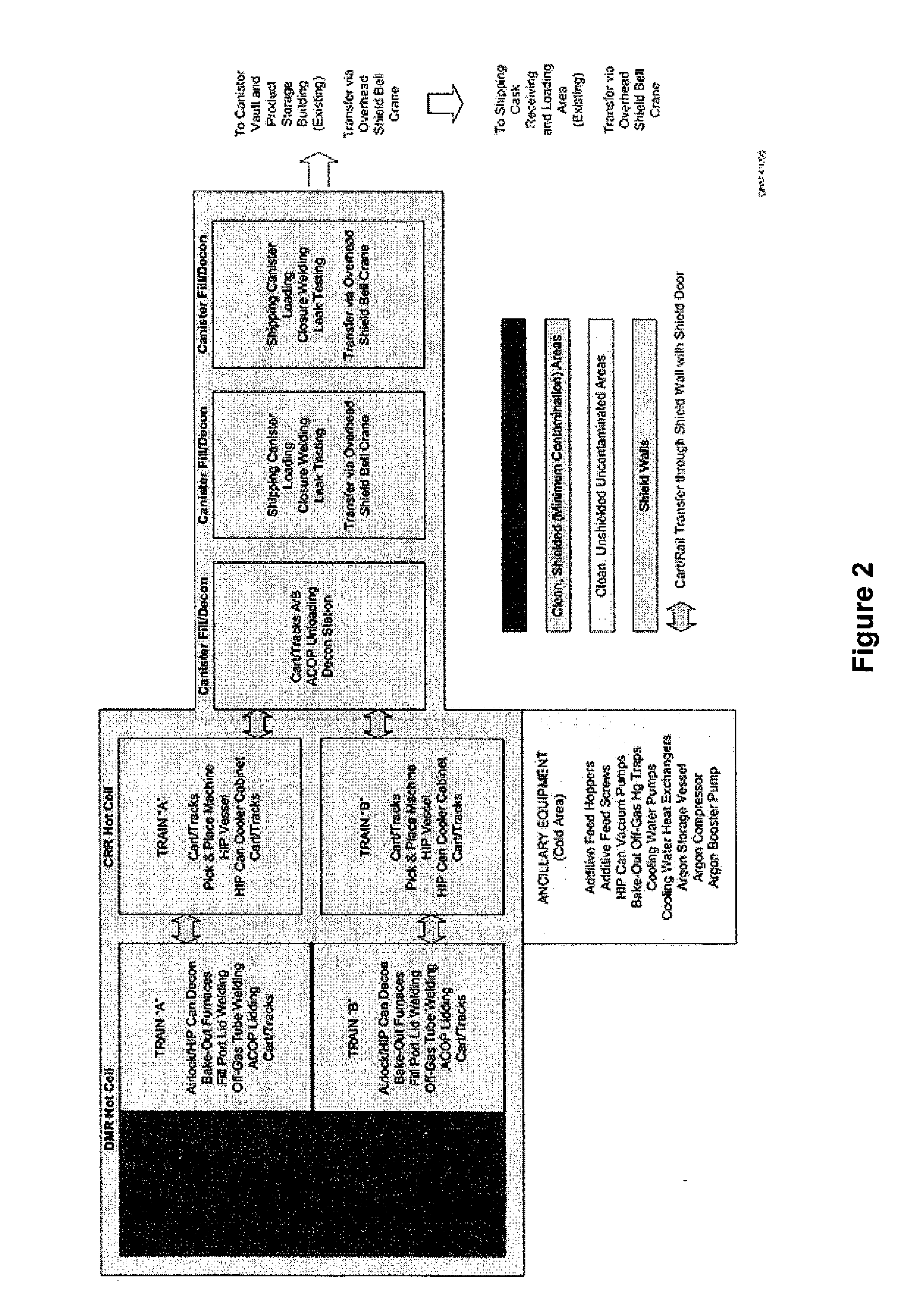

Method used

Image

Examples

Embodiment Construction

Definitions and Acronyms Used Herein

[0021]As used herein “calcine” is the solidified liquid waste stream remaining after first-cycle solvent extraction of uranium from SNF and the concentrated wastes from second- and third-cycle extraction of the fuel.

[0022]“Spent Nuclear Fuel” (SNF), may also be referred to as “Used Nuclear Fuel,” and is nuclear fuel that has been irradiated in a nuclear reactor (usually at a nuclear power plant) but is no longer useful in sustaining a nuclear reaction in an ordinary thermal reactor.

[0023]“Raffinate” is a product which has had a component or components removed. The product containing the removed materials is referred to as the extract. For example, in solvent extraction, the raffinate is the liquid stream which remains after solutes from the original liquid are removed through contact with an immiscible liquid. In metallurgy, raffinating refers to a process in which impurities are removed from liquid material.

[0024]“Fully Automated System” refers t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com