Processing method for wafer

a processing method and wafer technology, applied in the field of processing methods of wafers, can solve problems such as optical device wafers sometimes broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

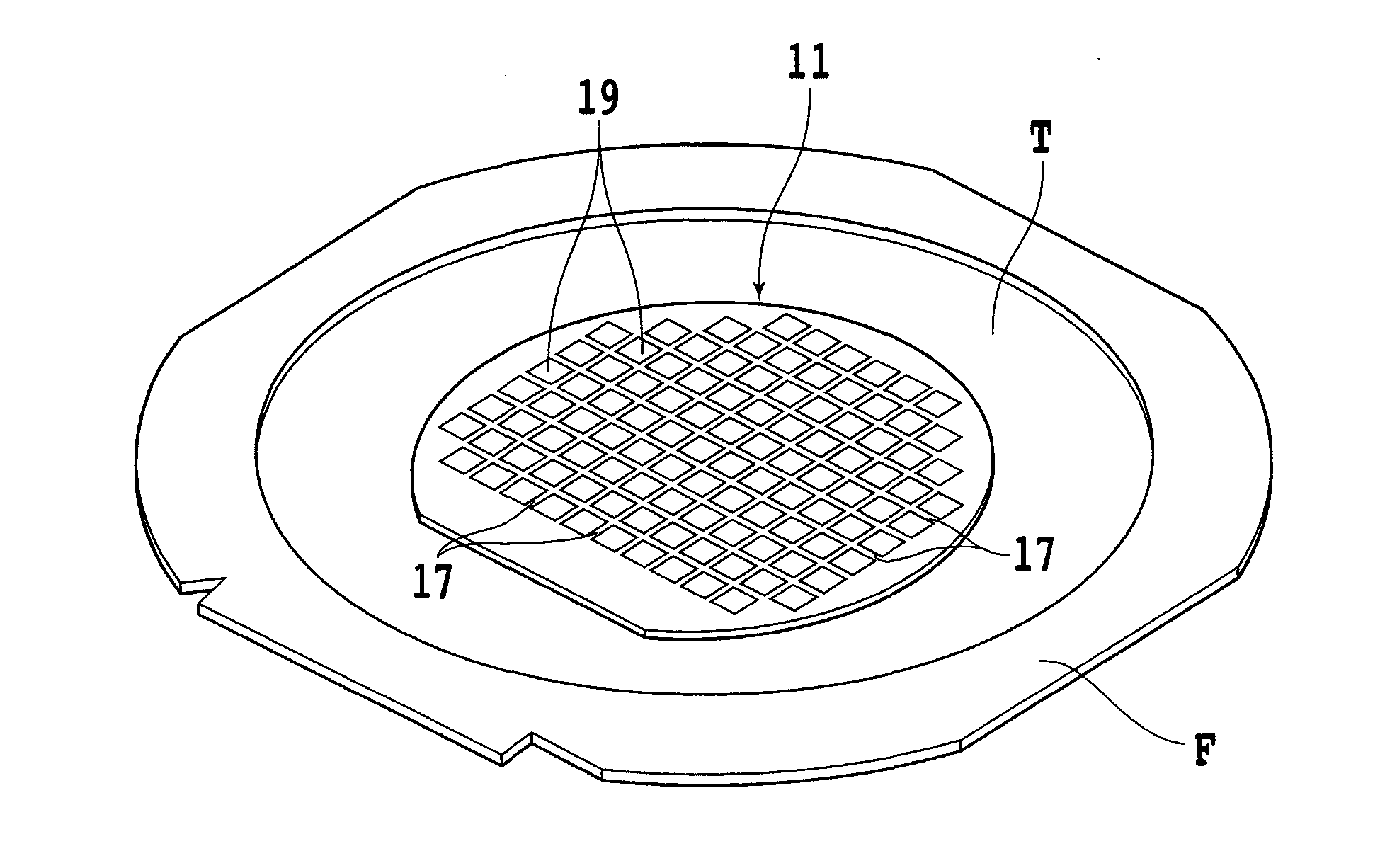

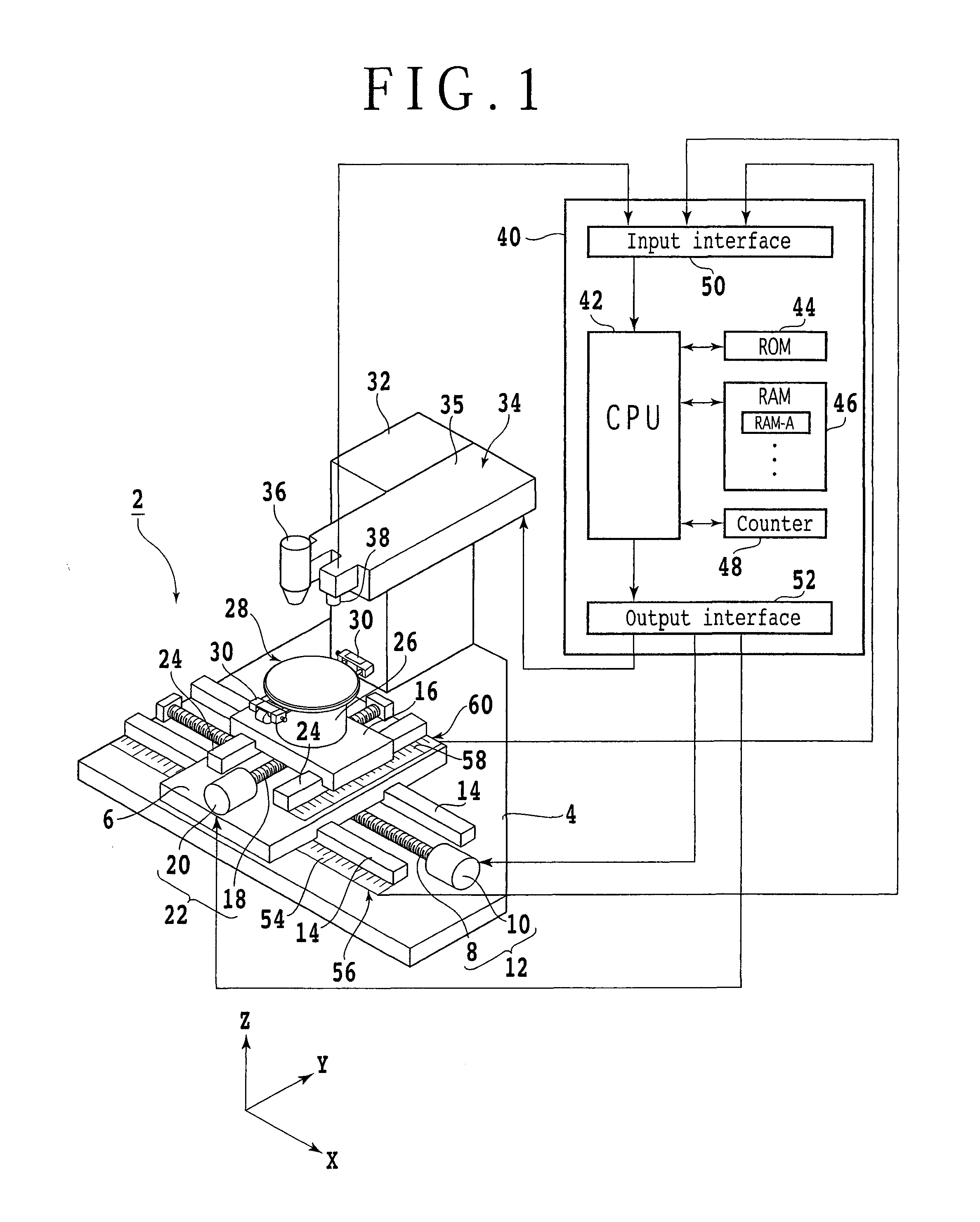

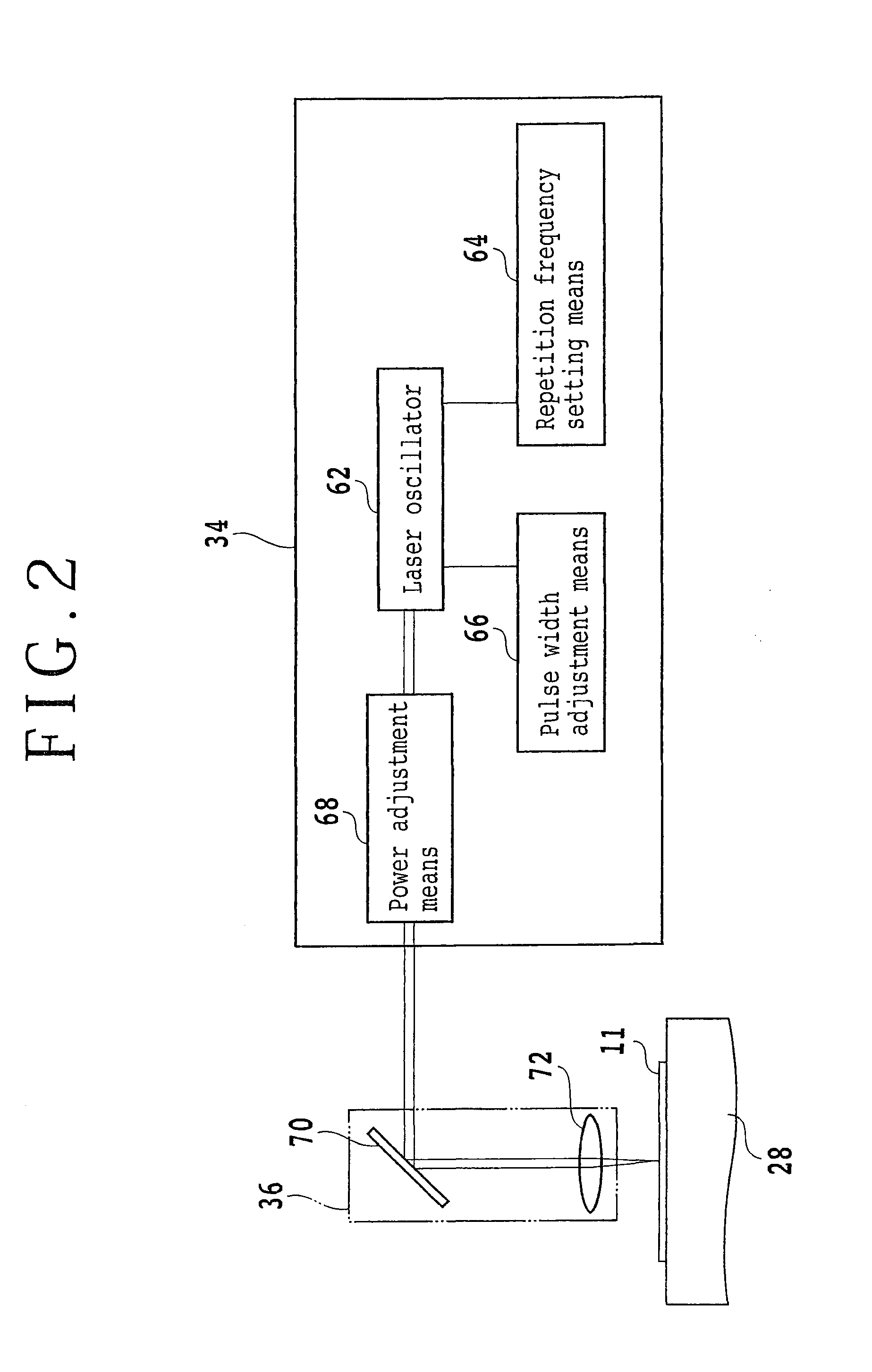

[0026]In the following, an embodiment of the present invention is described in detail with reference to the drawings. FIG. 1 shows a schematic block diagram of a laser processing apparatus 2 suitable for carrying out a modified layer forming step in a wafer processing method of the present invention. The laser processing apparatus 2 includes a first slide block 6 mounted for movement in an X-axis direction on a stationary base 4. The first slide block 6 is moved in a processing feeding direction, that is, in the X-axis direction, along a pair of guide rails 14 by processing feeding means 12 configured from a ball screw 8 and a step motor 10.

[0027]A second slide block 16 is mounted for movement in a Y-axis direction on the first slide block 6. In particular, the second slide block 16 is moved in an indexing direction, that is, in the Y-axis direction, along a pair of guide rails 24 by indexing feeding means 22 configured from a ball screw 18 and a step motor 20. A chuck table 28 is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width W1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com