Integrated solvent deasphalting and steam pyrolysis process for direct processing of a crude oil

a technology of integrated solvent and crude oil, which is applied in the direction of working up pitch/asphalt/bitumen by selective extraction, thermal non-catalytic cracking, and treatment with plural serial stages only, etc., and can solve the problems of coke formation in conventional heavy hydrocarbon pyrolysis operations, cost and energy-intensive process steps, and limited availability of feedstocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

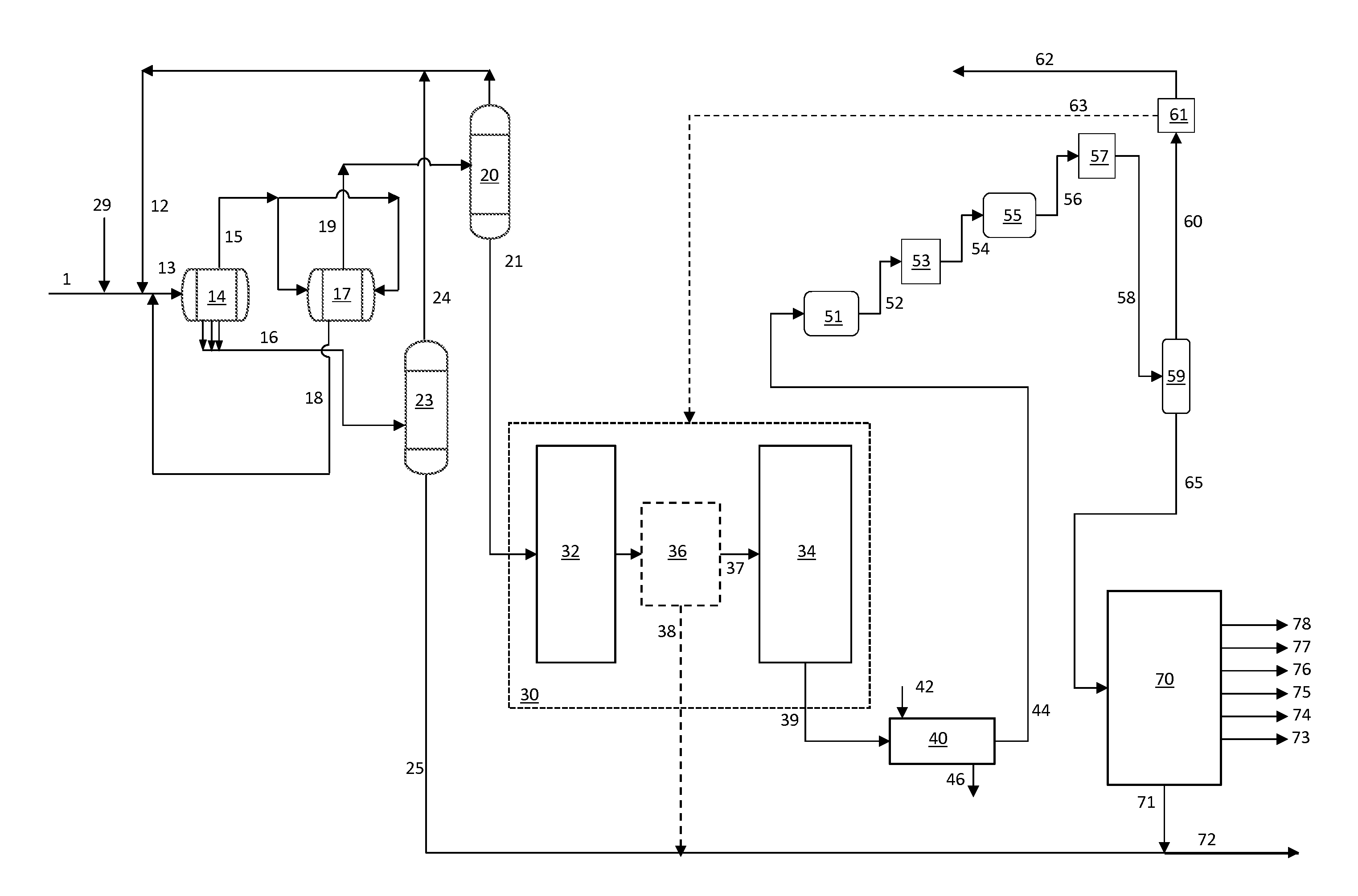

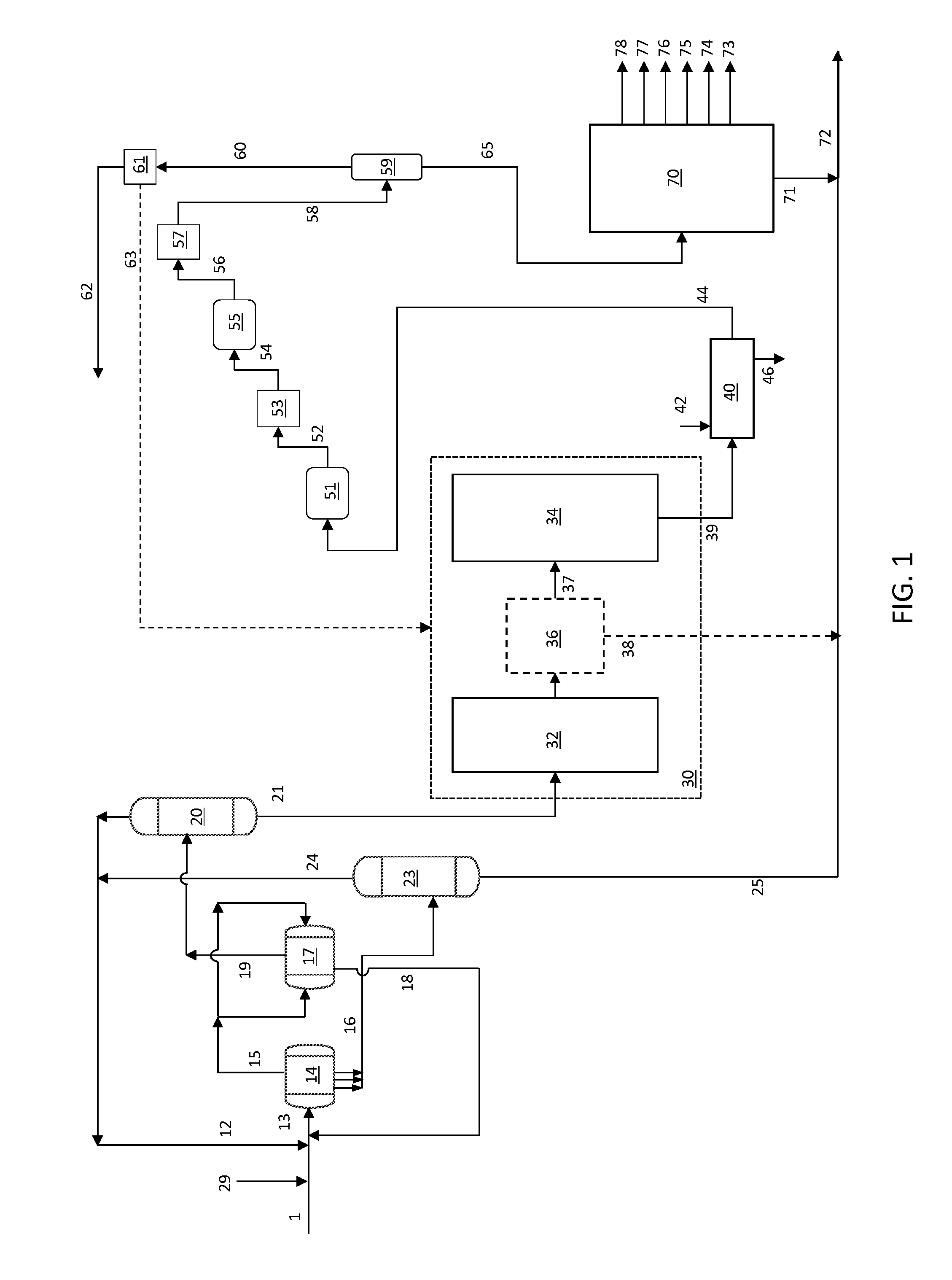

[0021]A flow diagram including an integrated solvent deasphalting and steam pyrolysis process and system is shown in FIG. 1. The integrated system includes a solvent deasphalting zone, a steam pyrolysis zone 30 and a product separation zone.

[0022]Solvent deasphalting zone generally includes a primary settler 14, a secondary settler 17, a deasphalted / demetalized oil (DA / DMO) separation zone 20, and a separator zone 23.

[0023]Primary settler 14 includes an inlet for receiving a combined stream 13 including a feed stream 1 and a solvent, which can be fresh solvent 29, recycle solvent 12, recycle solvent 24, or a combination comprising one or more of these solvent sources. Primary settler 14 also includes an outlet for discharging a primary DA / DMO phase 15 and several pipe outlets for discharging a primary asphalt phase 16. Secondary settler 17 includes two tee-type distributors located at both ends for receiving the primary DA / DMO phase 15, an outlet for discharging a secondary DA / DMO p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquid | aaaaa | aaaaa |

| physical | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com