Recovery of benzene and benzene derivatives from gasoline fractions and refinery streams

a technology of benzene derivatives and gasoline fractions, which is applied in the field of recovery of benzene and benzene derivatives from gasoline fractions and refinery streams, can solve the problems of high construction cost, inability to simply separate aromatics, and high solvent requirements, so as to achieve low solvent cost, improve properties, and improve solvent capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

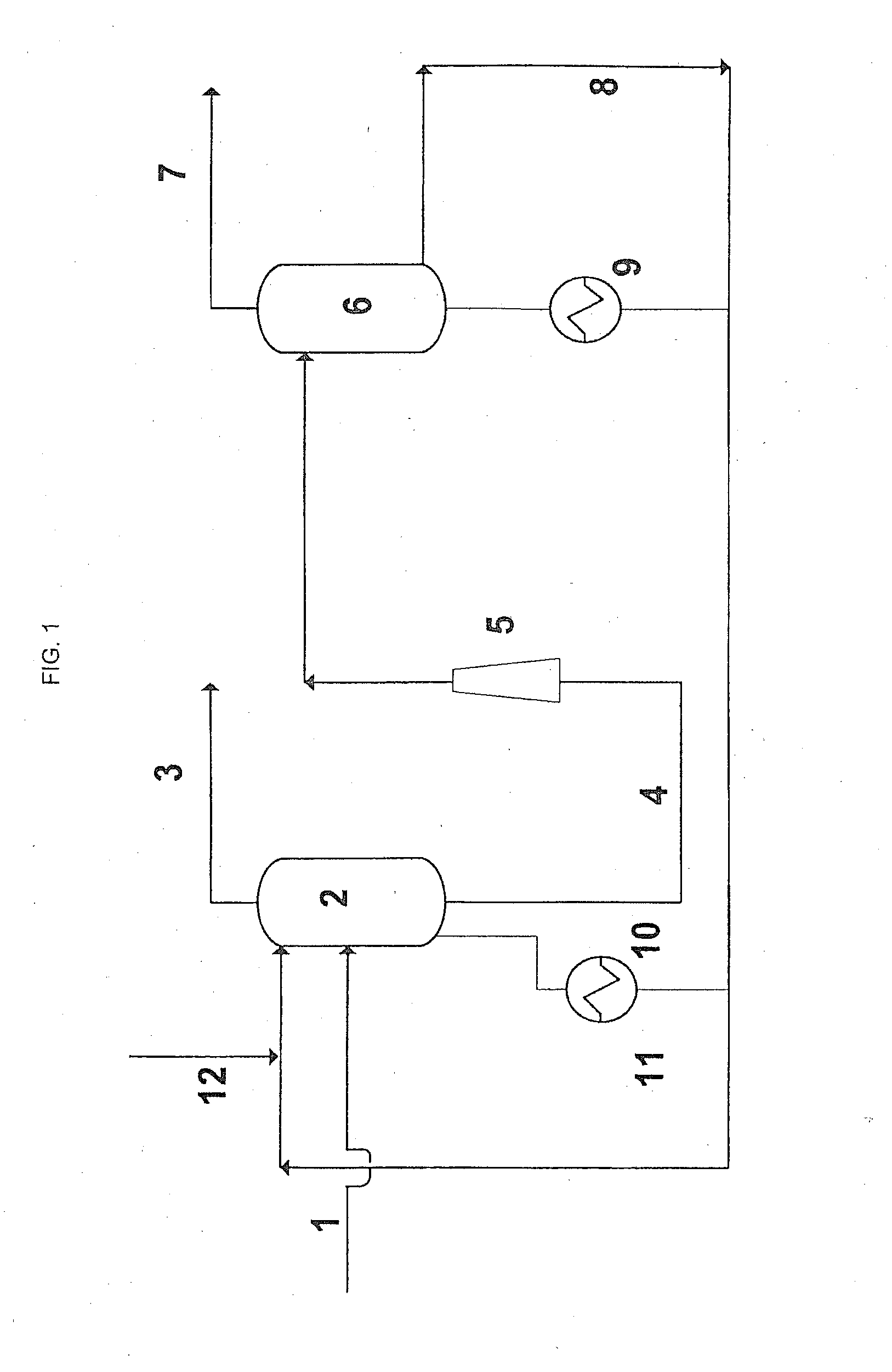

[0019]Claimed is a process for the recovery of a pure aromatics fraction containing benzene, toluene or xylene or mixtures of these aromatics from refinery streams or gasoline fractions containing such aromatics by way of extractive distillation, in which[0020]the feed product is subjected to a pre-distillation in a first process step prior to the extractive distillation, where the components which boil at higher temperatures than the mentioned aromatics are separated as a bottom product, and[0021]the thus obtained starting mixture containing aromatics is mixed in a second process step with an extracting solvent or solvent mixture which is capable of selectively increasing the fugacity of the non-aromatic components of the starting mixture and thus the separating efficiency, and submitted to an extractive distillation, and[0022]the extracting solvent from the obtained extract is distilled off in a third process step by increasing the temperature or increasing the temperature and red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass percent | aaaaa | aaaaa |

| mass percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com