Ferritic stainless steel excellent in corrosion resistance and strength of weld zone and tig welded structure

a technology of tig welding structure and ferrite stainless steel, which is applied in the field of ferritic stainless steel, can solve the problems of deterioration of corrosion resistance at the scale parts formed, rise in corrosion susceptibility, and fall in corrosion resistance, and achieve excellent in the corrosion crevice corrosion and the strength resistance of the weld zon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

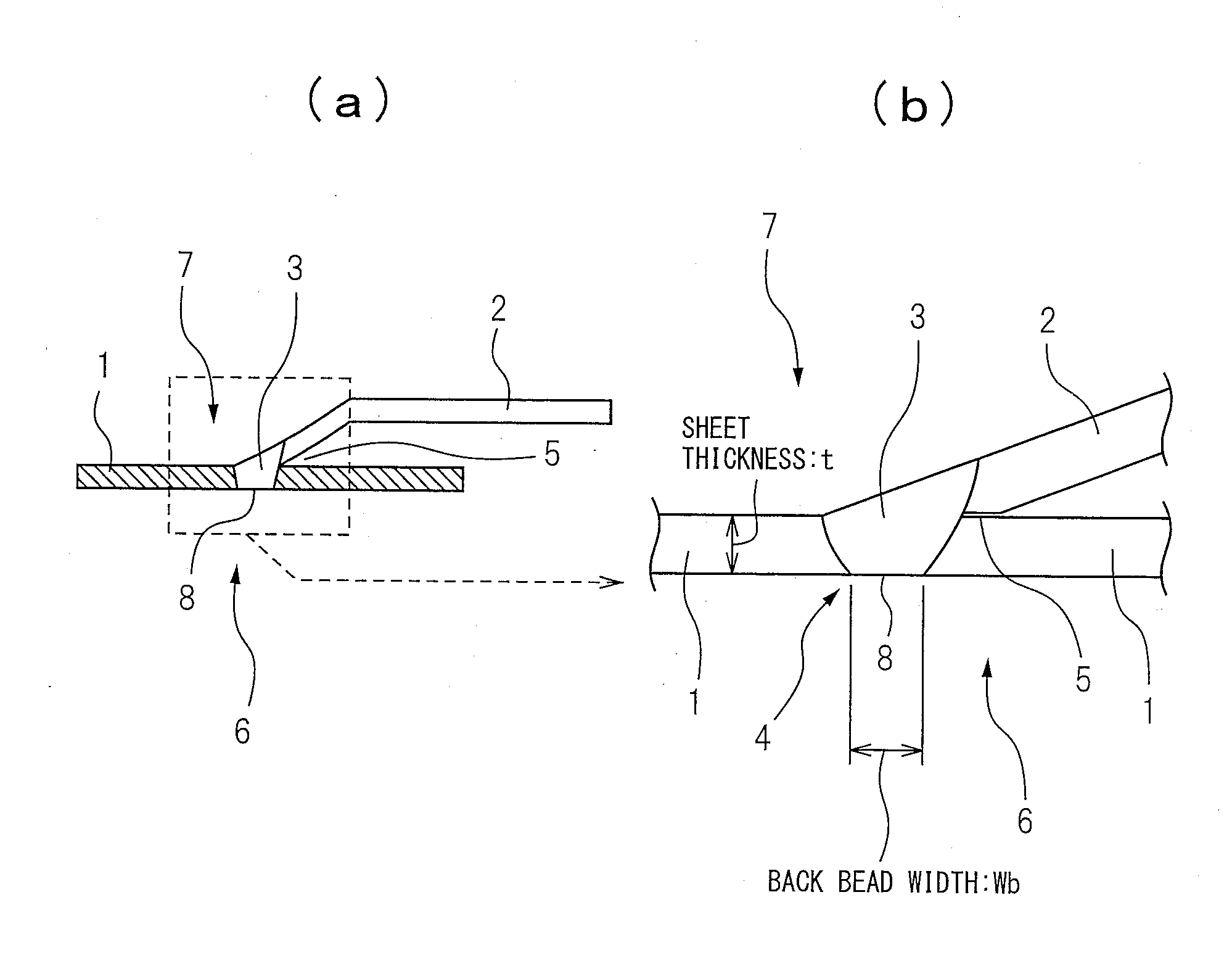

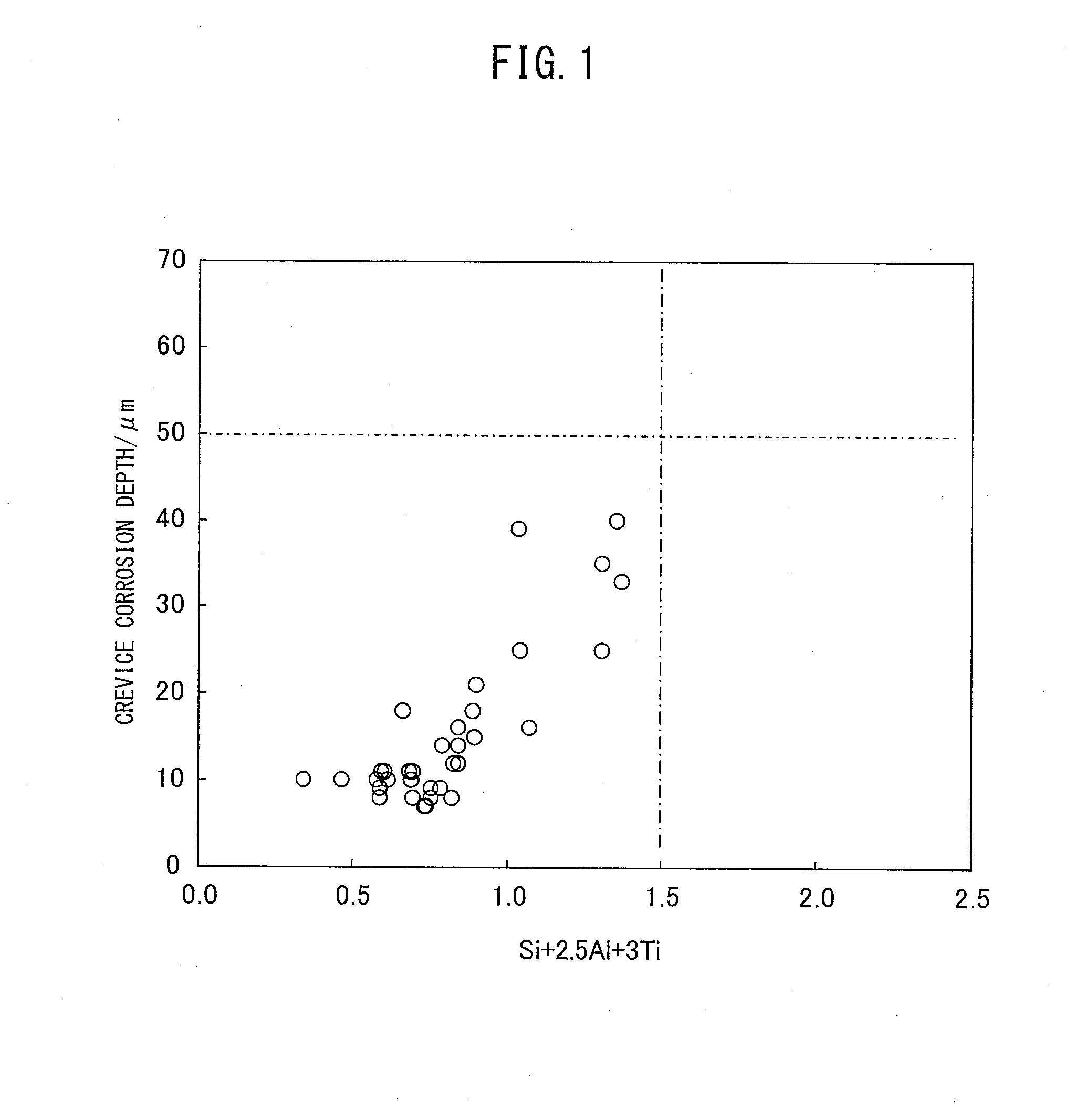

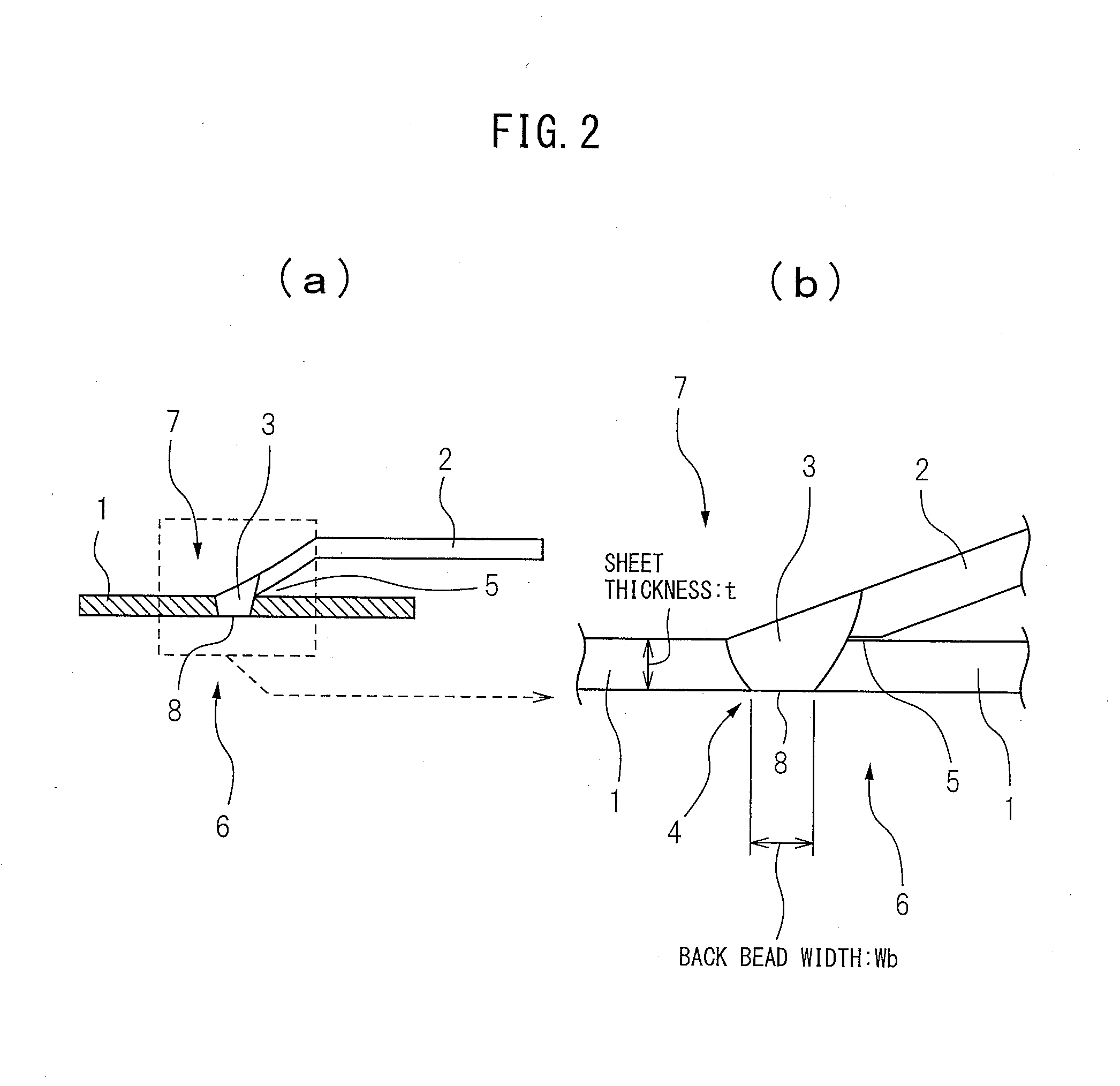

[0107]To evaluate the corrosion resistance of the TIG weld crevice part, the TIG weld test material having the crevice structure shown in FIG. 2 was used for evaluate the corrosion resistance.

[0108]For the test materials, test pieces comprised of ferritic stainless steels which have the chemical ingredients (compositions) shown in Table 1 were used. Sheets of sheet thicknesses of 0.8 mm were produced by the method shown in the above-mentioned “Production of Test Materials”. Two were combined to prepare a TIG weld test piece to give a crevice angle of 15°. The welding conditions included no Ar gas shield at only the anti-torch side (weld crevice part and back surface weld zone). The weld current was changed in value from 50 A to 120 A for the purpose of control of the back bead width of the weld zone.

[0109]The method of evaluation of the corrosion resistance was evaluation by the method shown in the above-mentioned “Corrosion Resistance Evaluation Test (Part 2)”. That is, the test so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass % | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com