Kinetic energy consumer mode control

a technology of kinetic energy and consumer mode, applied in the direction of position/direction control, exhaust treatment, vehicle components, etc., can solve the problems of unfavorable solid remainings and carbon particles, and achieve the effect of increasing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

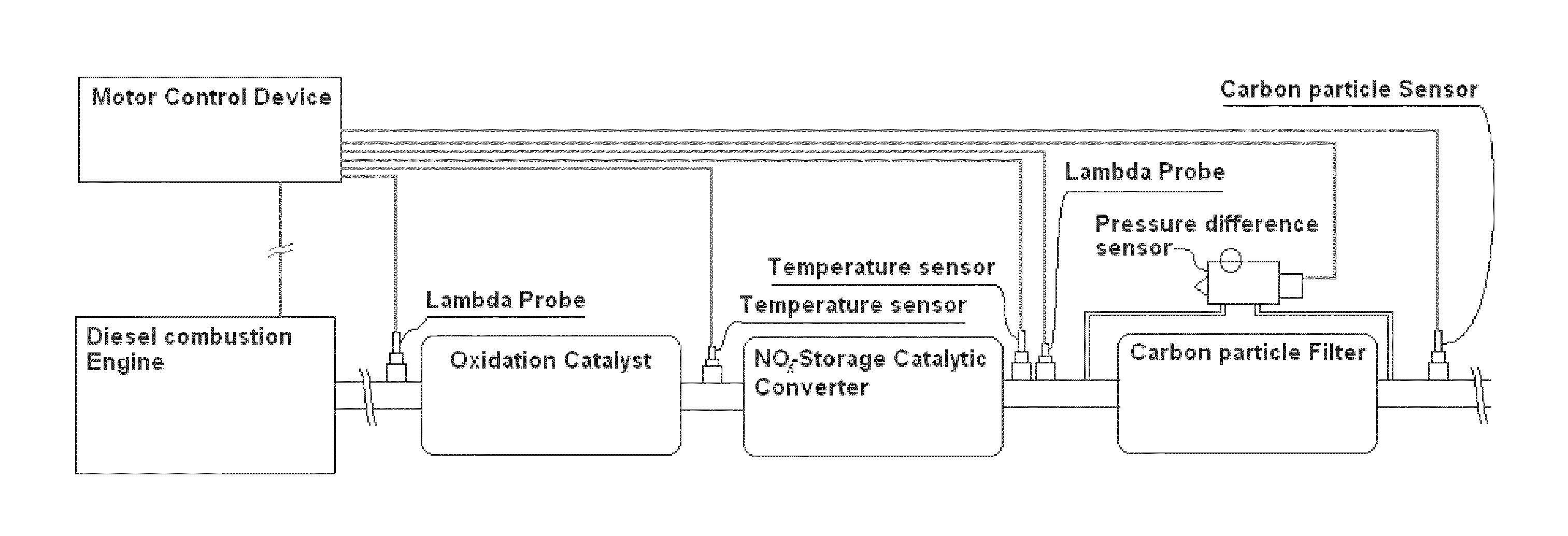

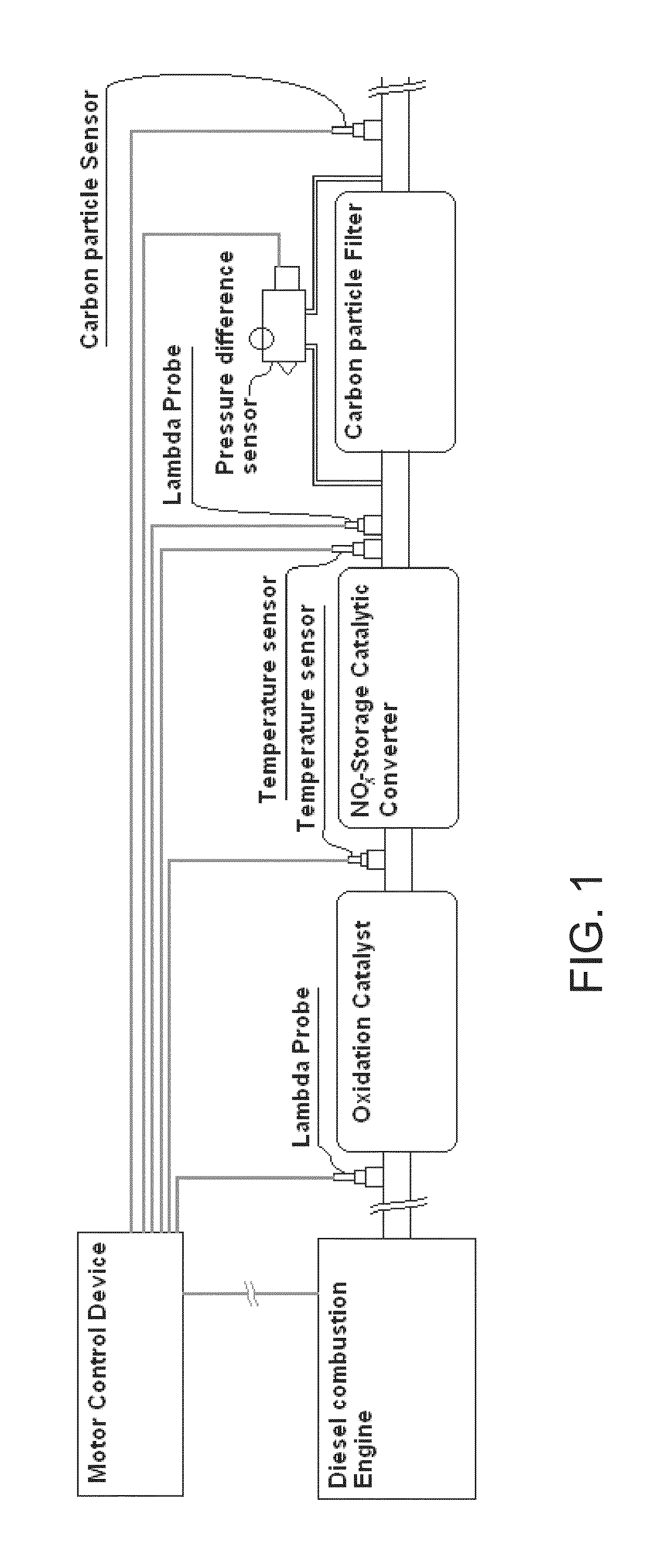

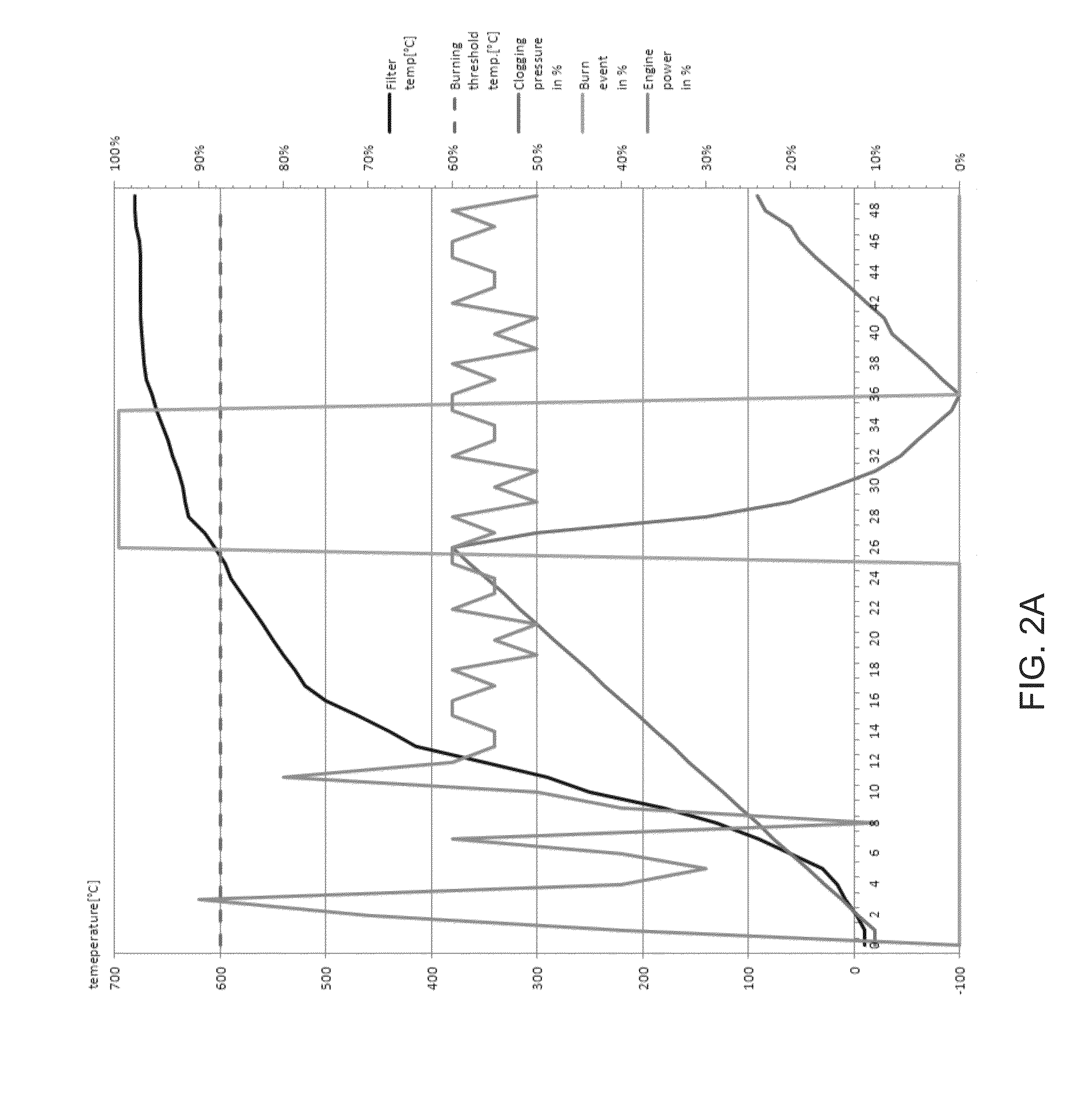

[0025]Engines, and in particular automotive diesel engines, produce as immediate exhaust a mixture of hot gases and solid particles, particularly solid carbon particles and the like. Passage of such particles out through a vehicle exhaust system is undesirable for a variety of environmental and health reasons. Thus, it is conventional to incorporate a particle filter or particle filtering means into a diesel vehicle exhaust system. The particle filter or screen functions to capture the particles so as to stop them from being exhausted out through the vehicle tail pipe. Of course, over a period of time (such as, for example, days or so), the particle filter or screen will begin to fill up or clog. Naturally, unless intervening means are provided, the screen or filter will become permanently clogged and cease to be useful. However, as the particle filter begins to fill up so as to be clogged with particles, the passage of gases therethrough is progressively impeded and thus a back pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com