Liquid-activated formulation with hot melt binding matrix

a technology of hot melt and liquid activation formulation, applied in the direction of inks, bands, transportation and packaging, etc., can solve the problems of limited color options, unreliable ph-based wetness indicators,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

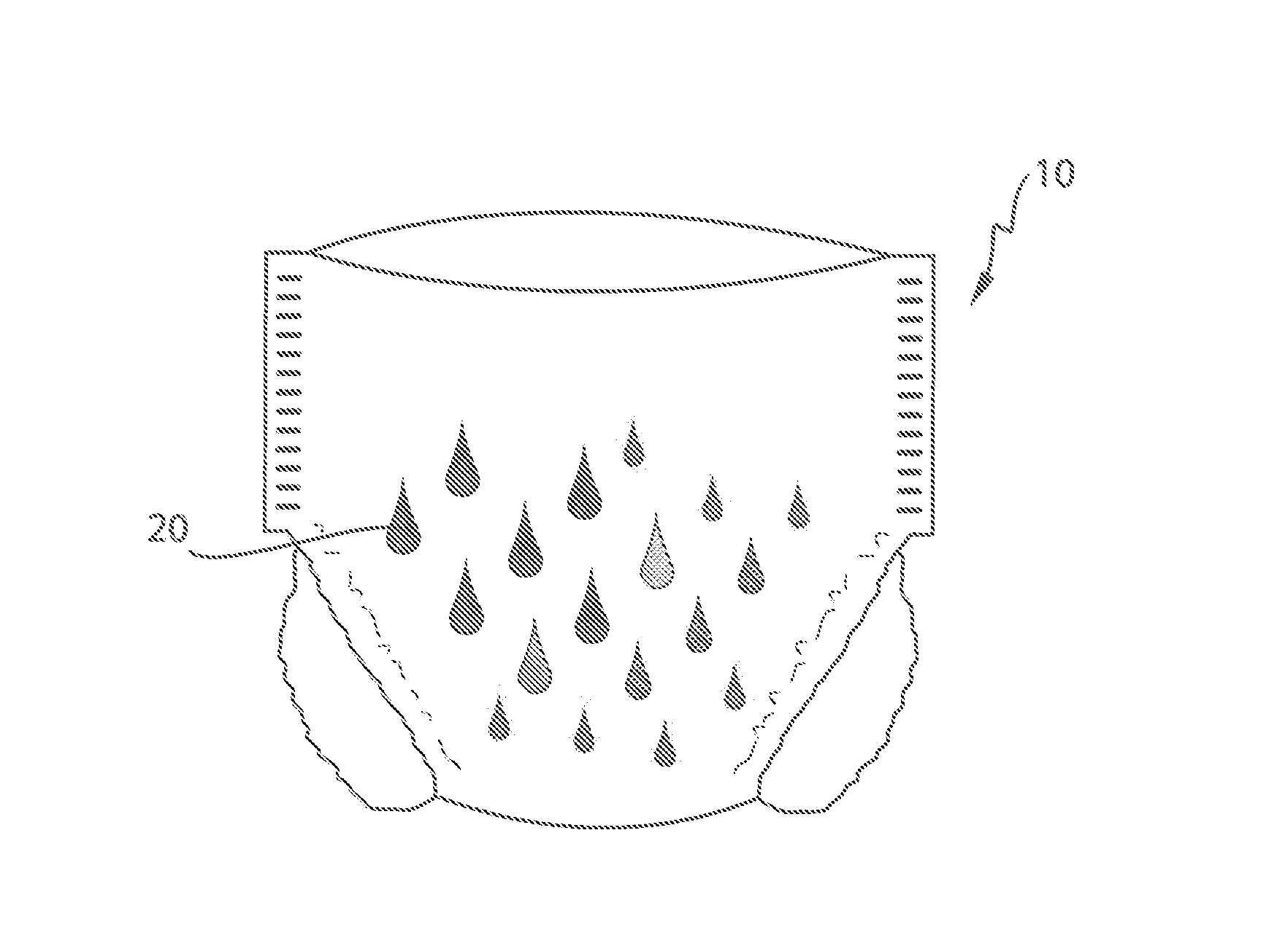

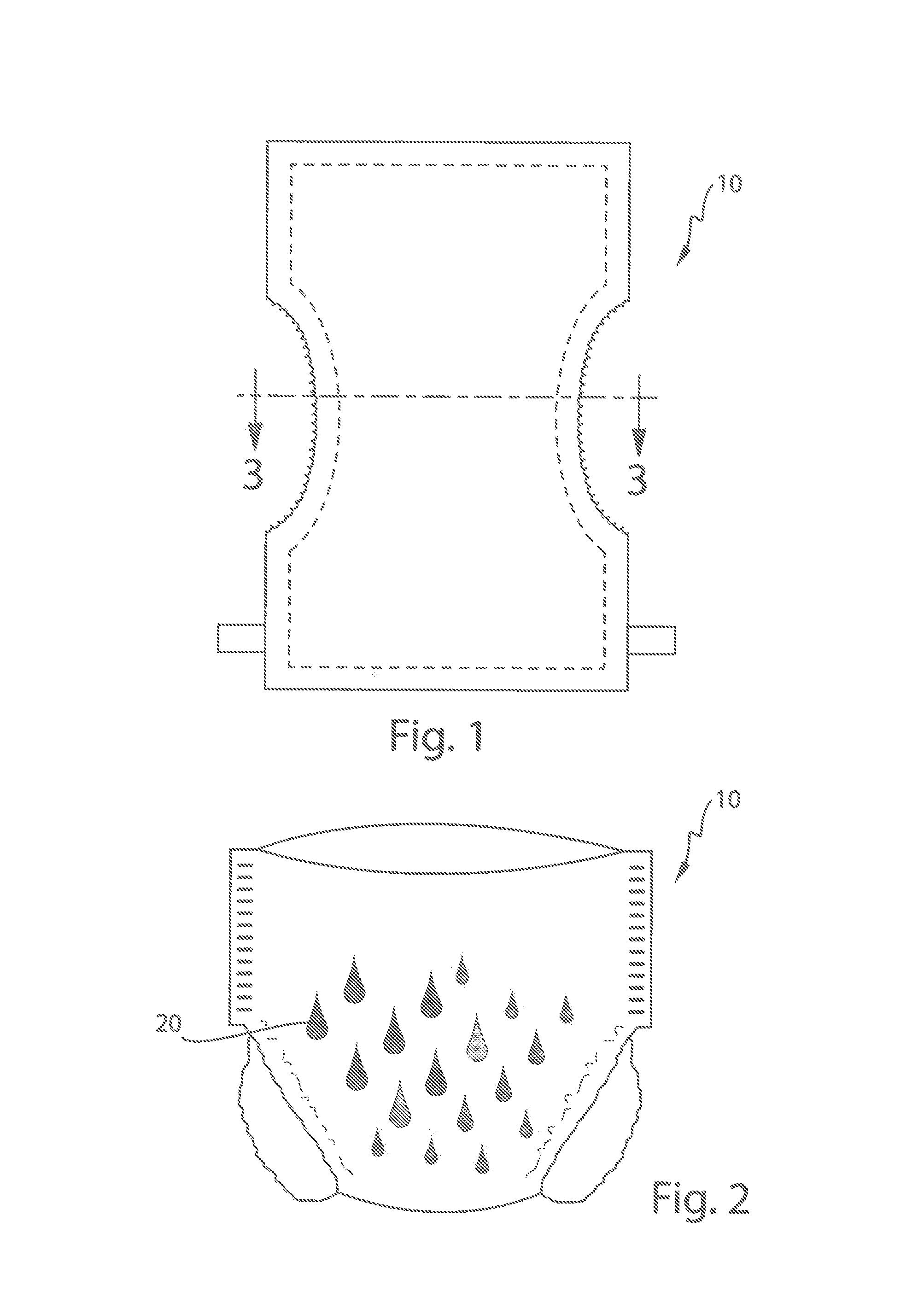

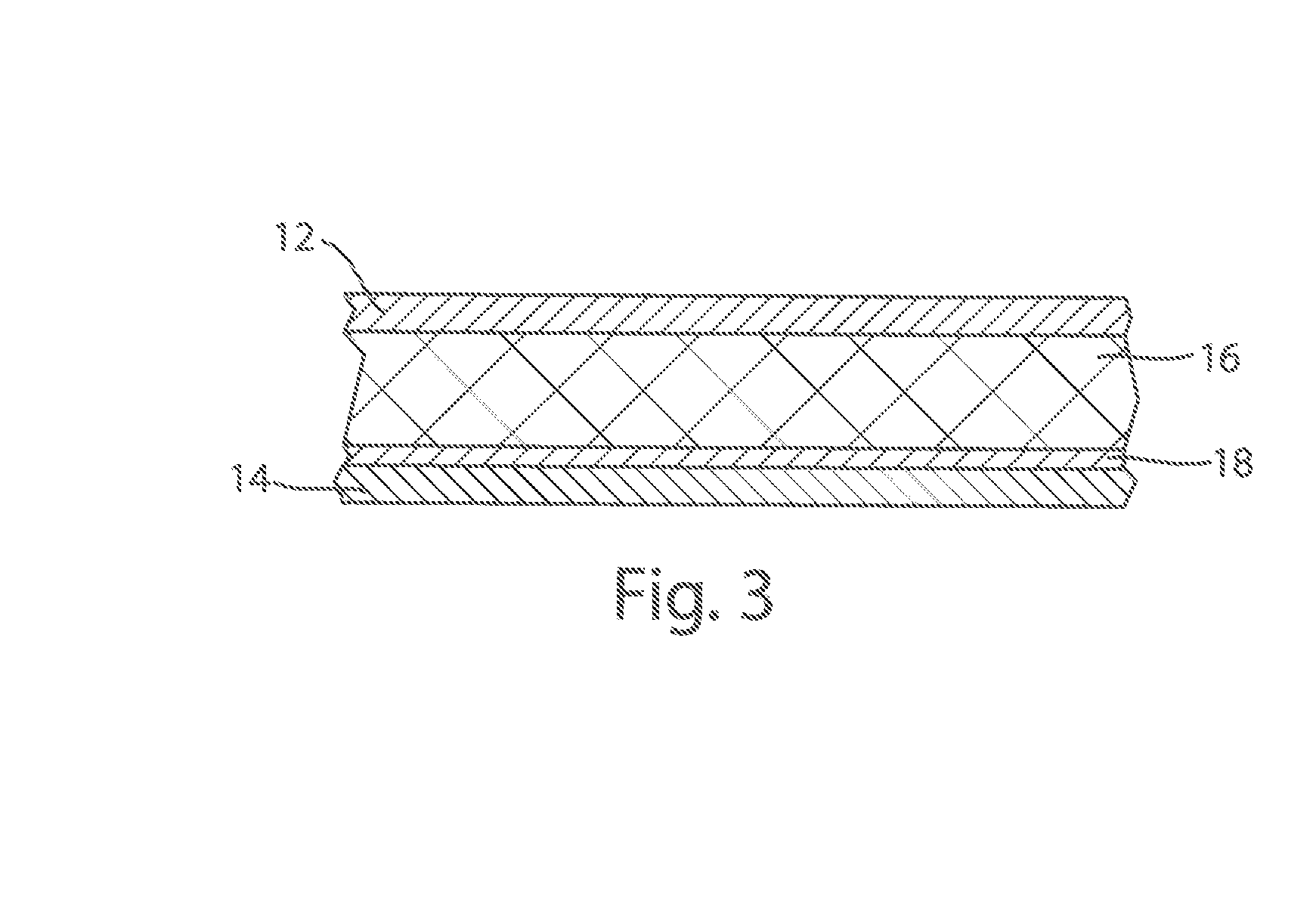

Image

Examples

examples

[0069]The present invention is illustrated by the following examples, which are merely for the purpose of illustration and are not to be regarded as limiting the scope of the invention or the manner in which it can be practiced. Unless specifically indicated otherwise, parts and percentages are given by weight. Examples may include any of the compositions and components disclosed in U.S. Patent Application Ser. No. 61 / 705,861, titled “Liquid Activated Color Change Ink and Methods of Use”.

INCI or Trade NameFUNCTION / SupplierSodium Aluminum Silicate48.20%Sipernat ™ 820AOpacifier / Evonik Inc.Bromocresol Green (Free Acid)0.30%Colorant / Curtiss LabsSodium Hydrogen Carbonate11.00%hydrochromic ioniccompound / Sigma-AldrichPerformathox 45026.00%C20-C40 Pareth-10Surfactant / New Phase Inc.Microcrystalline Wax11.00%Multiwax ™W-835Tackifier / SonnebornIsononyl Isononylnonoate1.50%Particle Wetting Agent / AlzoInc.Polyhydroxystearic Acid2.00%Dispersun ™ DSP-Particle WettingOL100Agent / Innospec Inc.100.00%EX...

examples 1-5

may be prepared in the following manner.

[0070]Those ingredients that are solids at room temperature are first melted at a temperature of around 90 C. These ingredients include the binding agents, hot melt adhesives, waxes, surfactants, and optional ingredients like the anti-oxidants. Typically, a temperature of around 80 C to 100 C would be required to melt these ingredients. After melting to the liquid state on a hot plate, the materials are well mixed using a propeller mixer like an IKA RW-20 (or similar mixer) until the mixture is homogeneous. While keeping this mixture heated and mixed, the Sodium Aluminum Silicate powder is homogeneously mixed into the composition. Next, the hydrochromic ionic compound, sodium hydrogen carbonate, is mixed into the composition while maintaining heating. Finally, the colorant like bromocresol green (free acid) is well mixed into the composition until the mixture is homogeneous. Heat can be maintained on the composition to make films using a draw-...

examples 6a and 6b

[0071]The top formula, example 6a, is made with water and coated onto the polyethylene film for color change performance observations. The composition right below, example 6b, is the composition's concentrations after the water has been removed from the wetness indicator film coating via heating with a heated blow dryer:

Joncryl 62418.40%Water36.08%Sipernat 820a22.90%m-cresol0.04%purplePEG-300022.27%NaOH / 50%0.31%Joncryl 62416.86%Water0.00%Sipernat 820a41.96%m-cresol0.08%purplePEG-300040.81%NaOH / 50%0.29%

[0072]Examples 6a and 6b may be prepared by the following steps:[0073]1) The Joncryl 624 Acrylic Polymer is weighed out into the beaker[0074]2) Water is weighed out and added. Mix with a spatula until homogeneous and milky white in appearance[0075]3) The Sipernat 820a Powder is added and mixed into the liquid until a viscous white and homogeneous paste results[0076]4) Weigh in the m-cresol purple and mix well[0077]5) Liquify the polyethylene glycol 3000 by heating and mix in well with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com