Method, apparatus and composition to increase recovery of hydrocarbons by reaction of selective oxidizers and fuels in the subterranean environment

a selective oxidizer and fuel technology, applied in the direction of fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of significant resource remaining out of technical reach, unfavorable hydrocarbon recovery, and inability to meet the needs of the environment, so as to improve the recovery rate and enhance the production. , the effect of improving the recovery ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

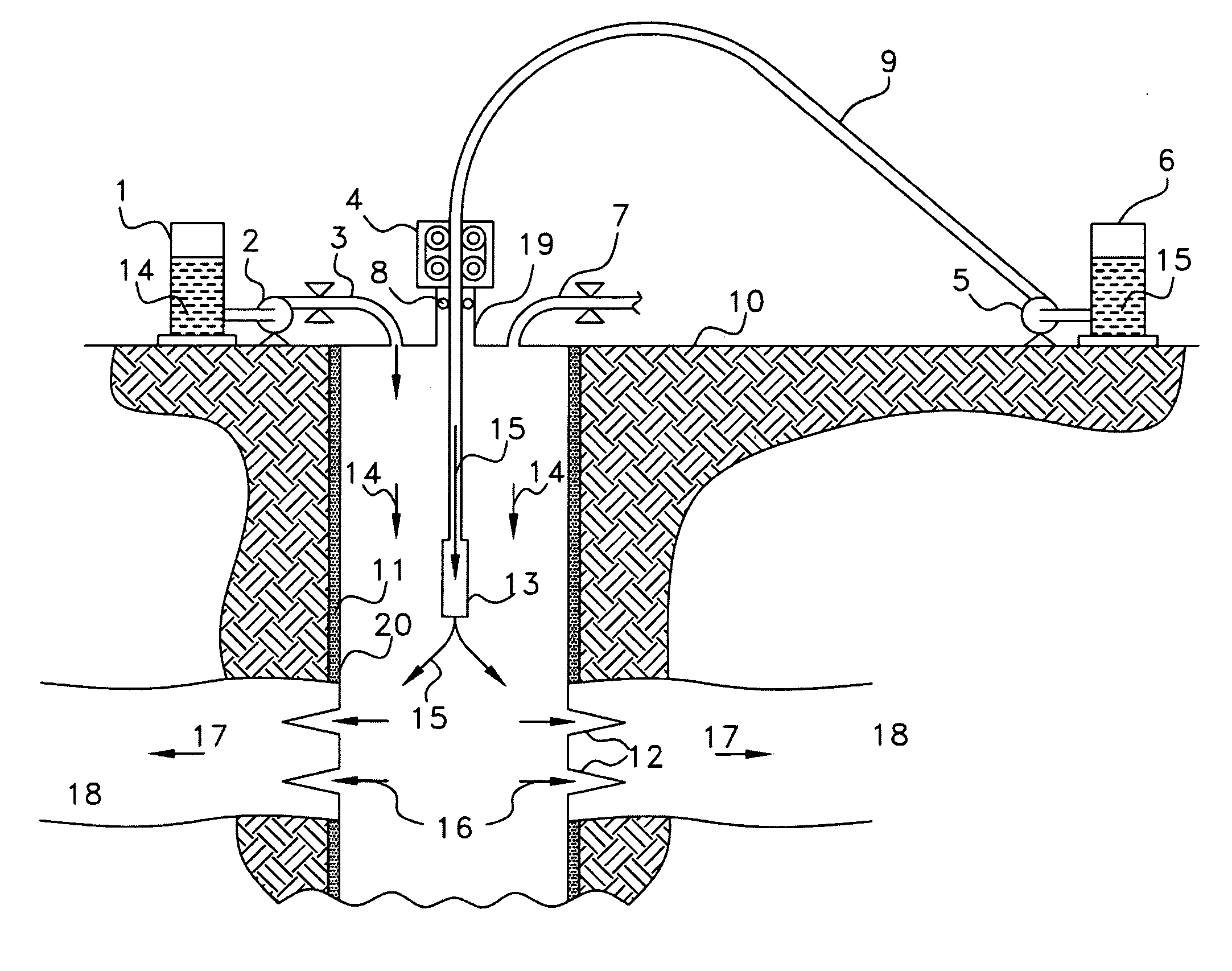

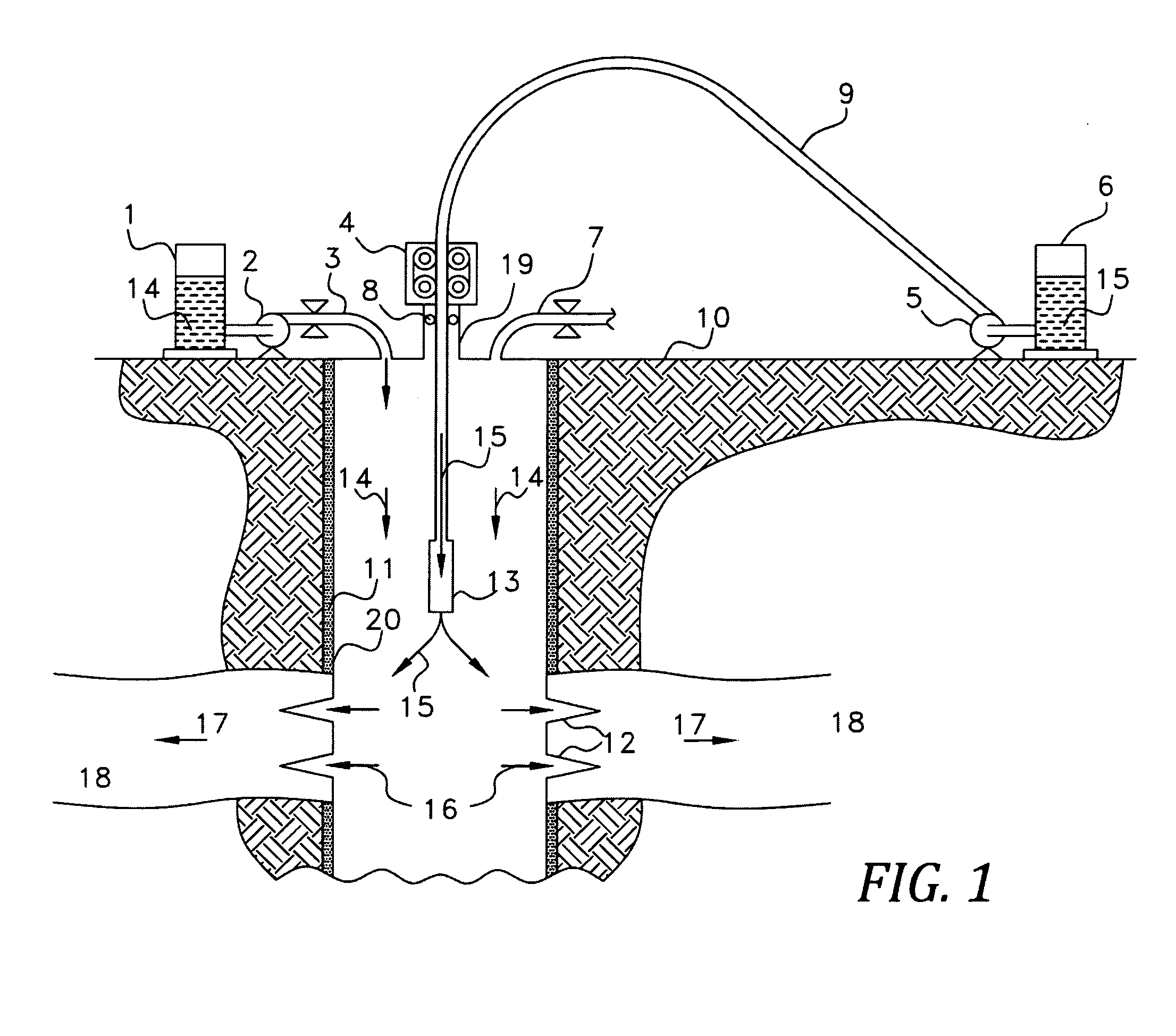

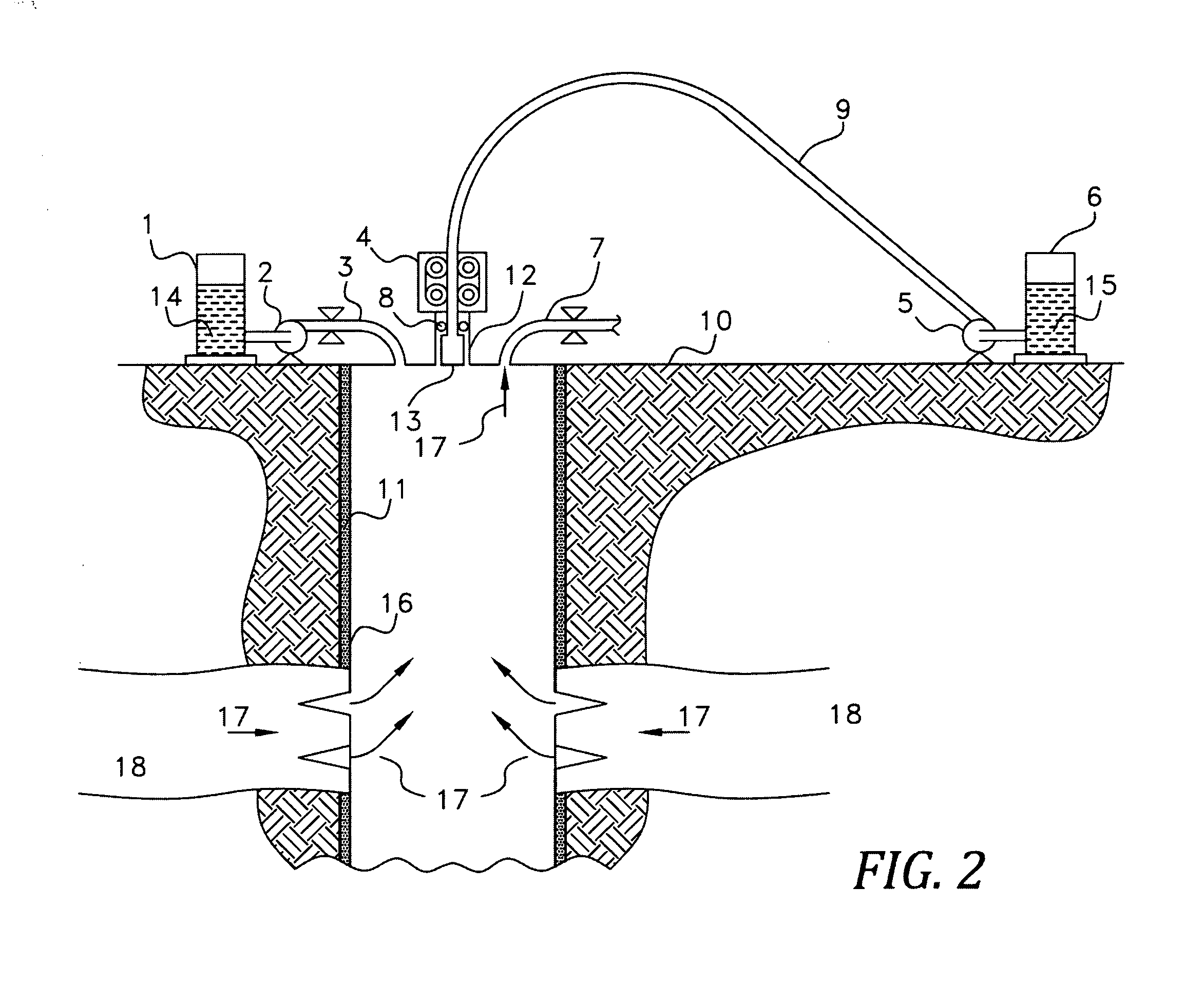

Image

Examples

Embodiment Construction

[0014]As used herein, “a” or “an” includes one or more. Where the present disclosure refers to “perforations” it should be understood to include “one or more perforations.”

[0015]As used herein, “surface” or “surface of the earth” refers to locations approximately at, or at or near the surface of the earth.

[0016]As used herein, “hydraulic fracturing” refers to a method of injecting a fluid above the fracture pressure of a subterranean reservoir into which the fluid is injected, or any propagation of fractures in a reservoir in strata (e.g. a rock layer) as a result of a pressurized fluid.

[0017]As used herein, “stimulation” refers to a method of injection a fluid below the hydraulic fracture pressure of a reservoir wherein the fluid is being injected.

[0018]As used herein “proppant” refers to any solid material that has sufficient strength to resist the overburden forces of the earth in a reservoir into which it is introduced or pumped, for example, any material that will keep a hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com