Pulping processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

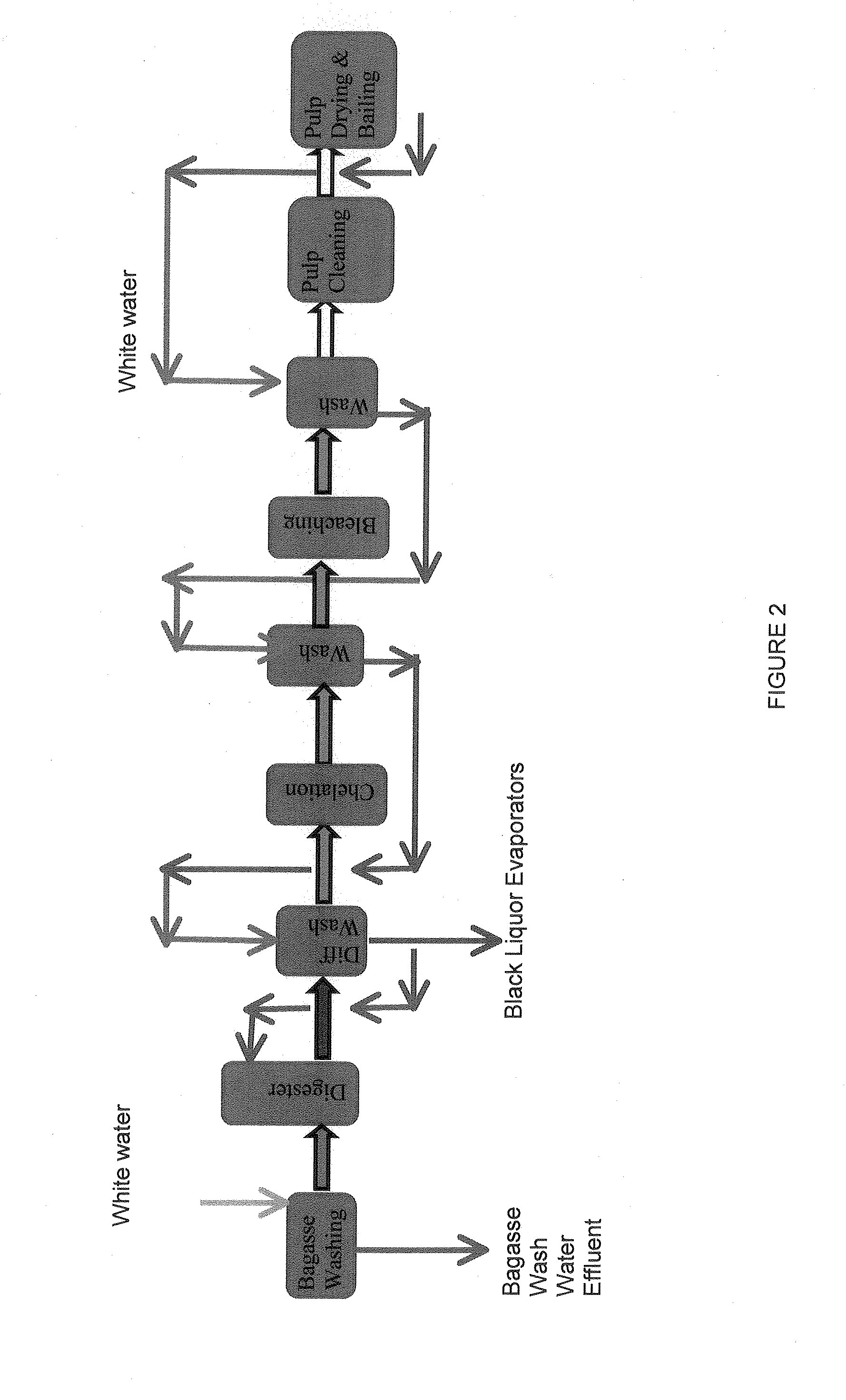

Cleaning of Raw Fibers

[0074]Bagasse was used as an example of raw fibers. Bagasse was first hydrated for 10 minutes with hot clean water (temperature of water was above room temperature, about 40° C., or 60° C.), under moderate agitation, at a consistency of 0.5% to 2.0%. Pith and sand were separated from the fibers in a Trammel Screen, which was a rotating drum that lifted and dropped the material and accepted water and pith through ⅛th inch holes up to ½″ holes. The rejected material was collected and removed from the screen to prevent accumulation, and disposed, and was dried before added into the pulping process. The washing yield was about 80% or higher, or about 85.9%, depending on quality of the bagasse starting material.

example 2

Soda AQ Pulping of Bagasse

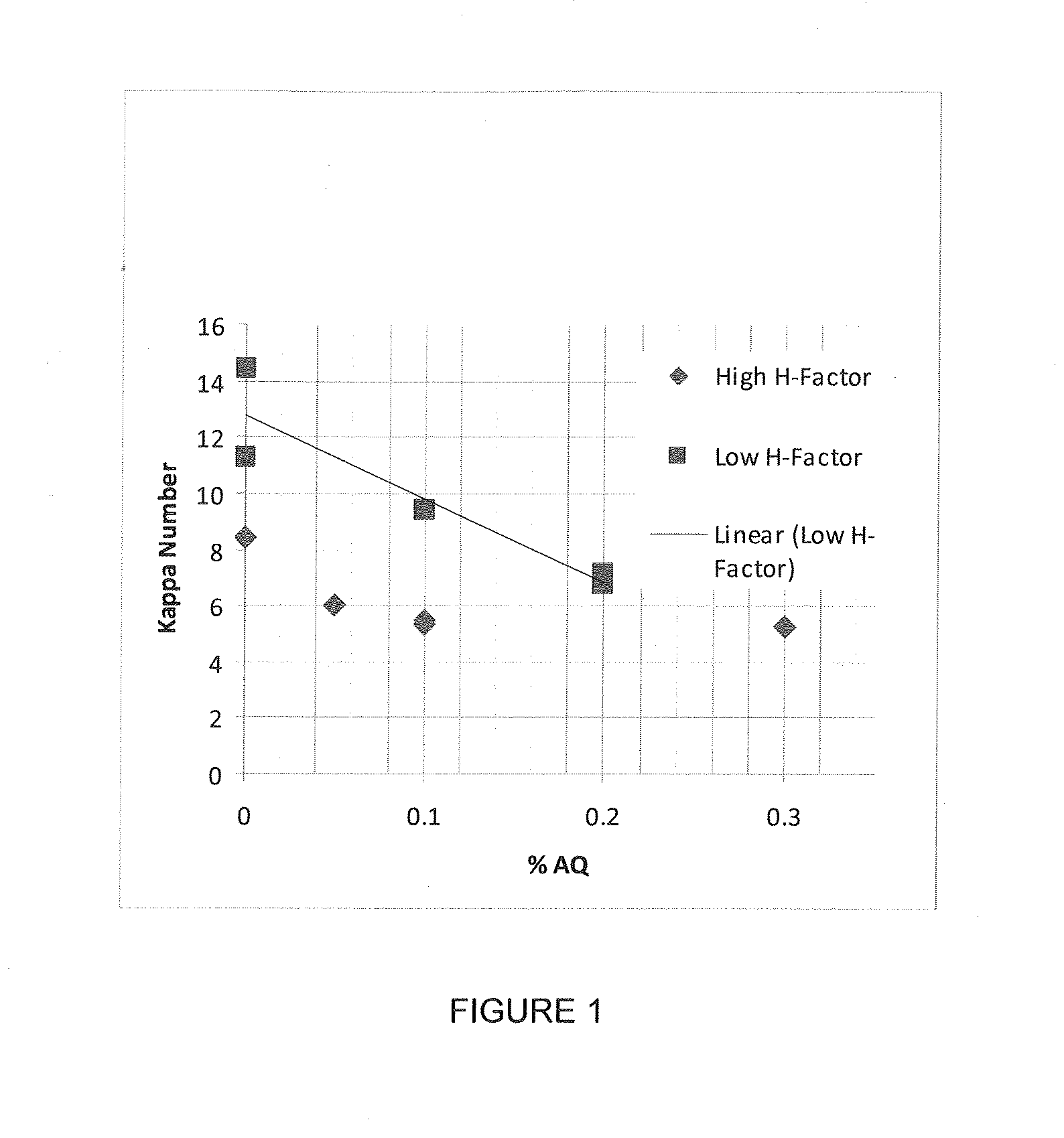

[0075]OD bagasse (cleaned as described in Example 1, Kappa number was 89) was treated with sodium hydroxide (20% by weight of the OD bagasse) and AQ (0.3% by weight to the dry weight of OD bagasse) at a liquid to dry fiber ratio of 7 (consistency of about 12.5%), at maximum temperature of about 175° C. for 35 or 40 minutes. Time to the maximum temperature was 60 minutes.

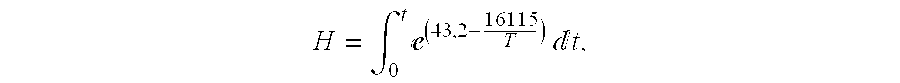

[0076]The target H-factor was 1060, as low as 20, and as high as 3000, and the temperature of the pulping reaction was 120° C. to 185° C. The Kappa number of the obtained pulp was 4.5.

example 3

Washing of Pulp

[0077]A pulp obtained from Example 2 was washed in a pressure diffuser washer designed specifically to accomplish all washing with a single unit without introducing undesired modifications to the pulp. The temperature of the wash water was chosen to cool the pulp temperature to about 100° C., 95° C., 90° C., 85° C., 80° C. or lower. The output went to a bleaching step and was cooled to 100° C. or less to prevent flashing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com