Method for dyeing golf balls and dyed golf balls

a golf ball and golf ball technology, applied in the dyeing process, solid balls, sport equipment, etc., can solve the problems of high cost of golf balls with customized pigments, limited customization of golf balls, and significant cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

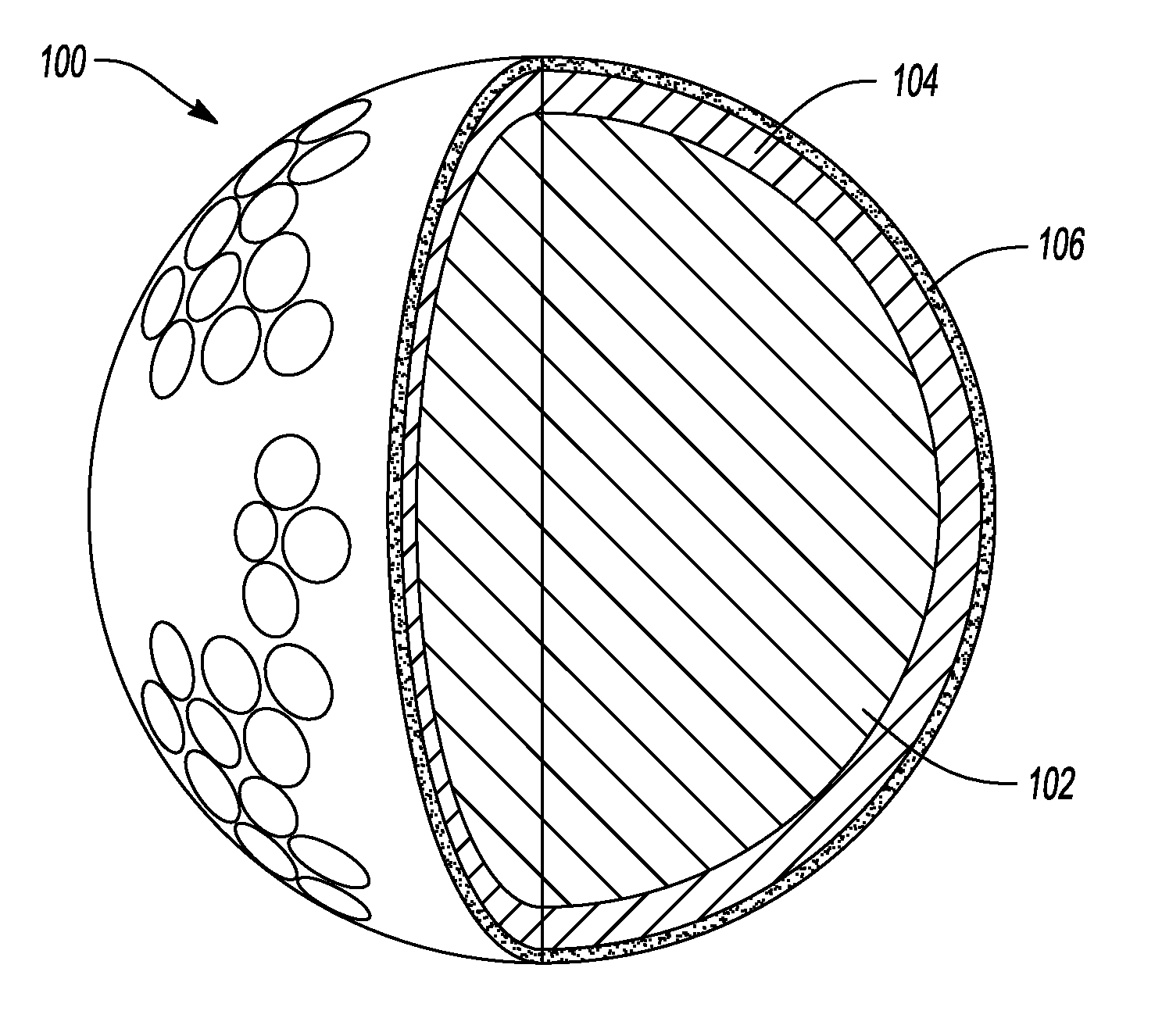

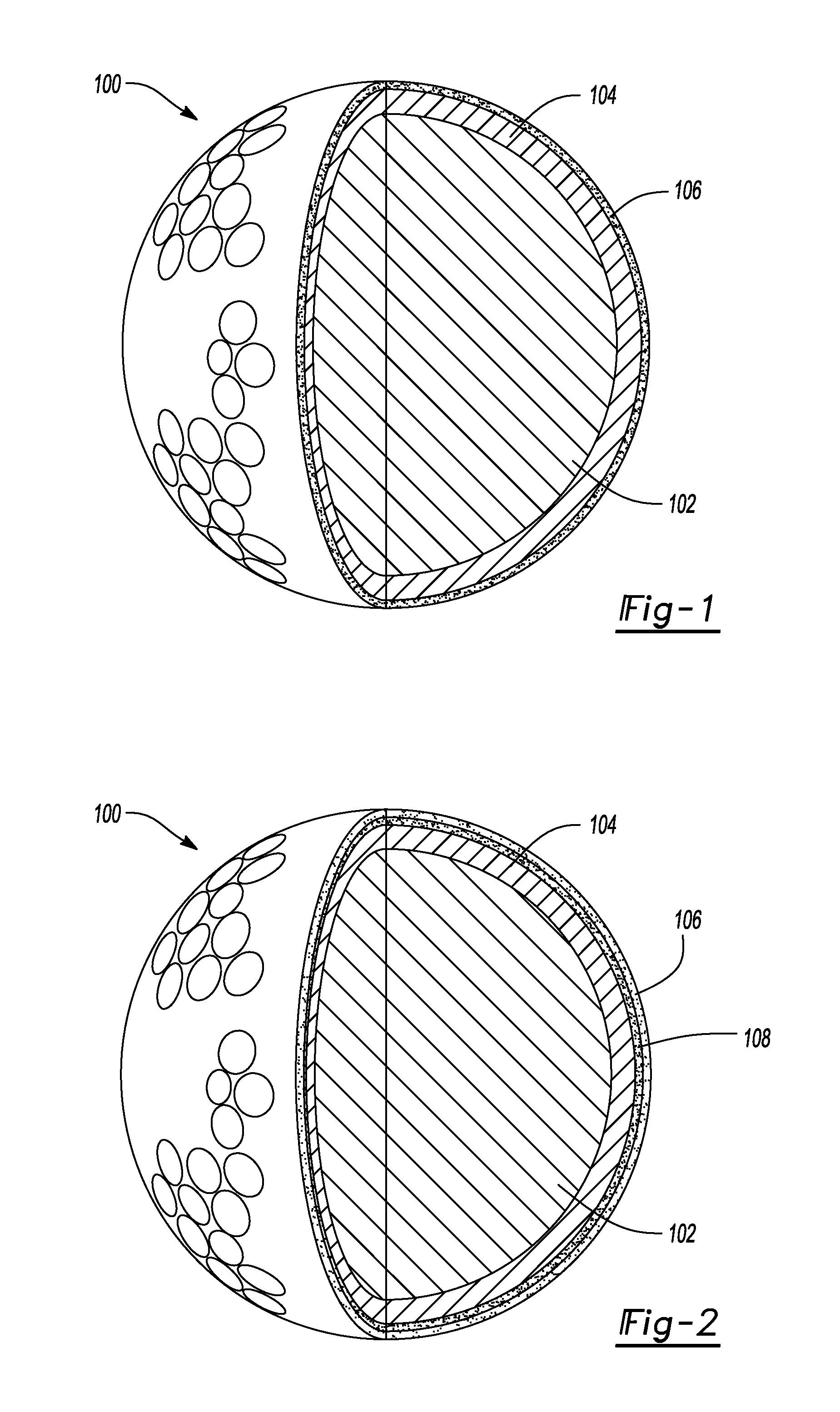

Image

Examples

example 1

[0091]A dye solution was prepared by dissolving Luminous Yellow 8G FF (obtained from Zenith Chemical Industries Limited) at a concentration of 0.2 g / liter in a solution of 75% by weight deionized water and 25% by weight n-propanol to produce a fluorescent color. Commerically available golf balls with a thermoplastic polyurethane cover (20XI, from Nike, Inc.), both coated with a clear two-part polyurethane coating and uncoated, were processed as follows:

[0092]Process 1: dye solution temperature 40° C., dye time 3 minutes;

[0093]Process 2: dye solution temperature 40° C., dye time 10 minutes;

[0094]Process 3: dye solution temperature 70° C., dye time 3 minutes;

[0095]Process 4: dye solution temperature 70° C., dye time 10 minutes. The processing variable are depicted in Table 1.

TABLE 1Dye solution temperature40° C.70° C.Dyeing time 3 minutesProcess 1Process 310 minutesProcess 2Process 4

[0096]Dye penetration in the dyed balls is recorded in Table 2.

TABLE 2Dye penetration average,micromete...

example 2

[0097]An uncoated commerically available golf ball with a thermoplastic polyurethane cover (20XI, from Nike, Inc.) was dyed in a solution containing a purple acid dye using Process 4 conditions as described in Example 1. Dye penetration was measured as 56 micrometers.

example 3

[0098]Commerically available golf balls with a thermoplastic polyurethane cover (20XI, from Nike, Inc.) were coated with a clear two-part polyurethane coating and then dyed by Process 4 as described in Example 1. The following variables were measured before and after the dyeing process:

1) Diameter measured in mm and established by measuring ball diameter in 5 places and averaging.

2) Weight measured in grams.

3) Surface hardness measured with JIS-C durometer-type gauge.

4) Ball compression measured as mm deflection between a load of 10 kg 130 kg and the deflection recorded in mm where the 10 kg load is 0.00 mm deflection and at a load of 130 kg using an ADC Compression Tester.

5) Coefficient of restitution COR) measured by shooting the ball through a pneumatic cannon (manufactured by ADC) at 125 ft / sec and dividing the in-bound or return velocity by the outbound or initial velocity, expressed as a decimal which represents % rebound. The measurements are shown in Table 3.

TABLE 3One month...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com