Anode and method of operating an electrolysis cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

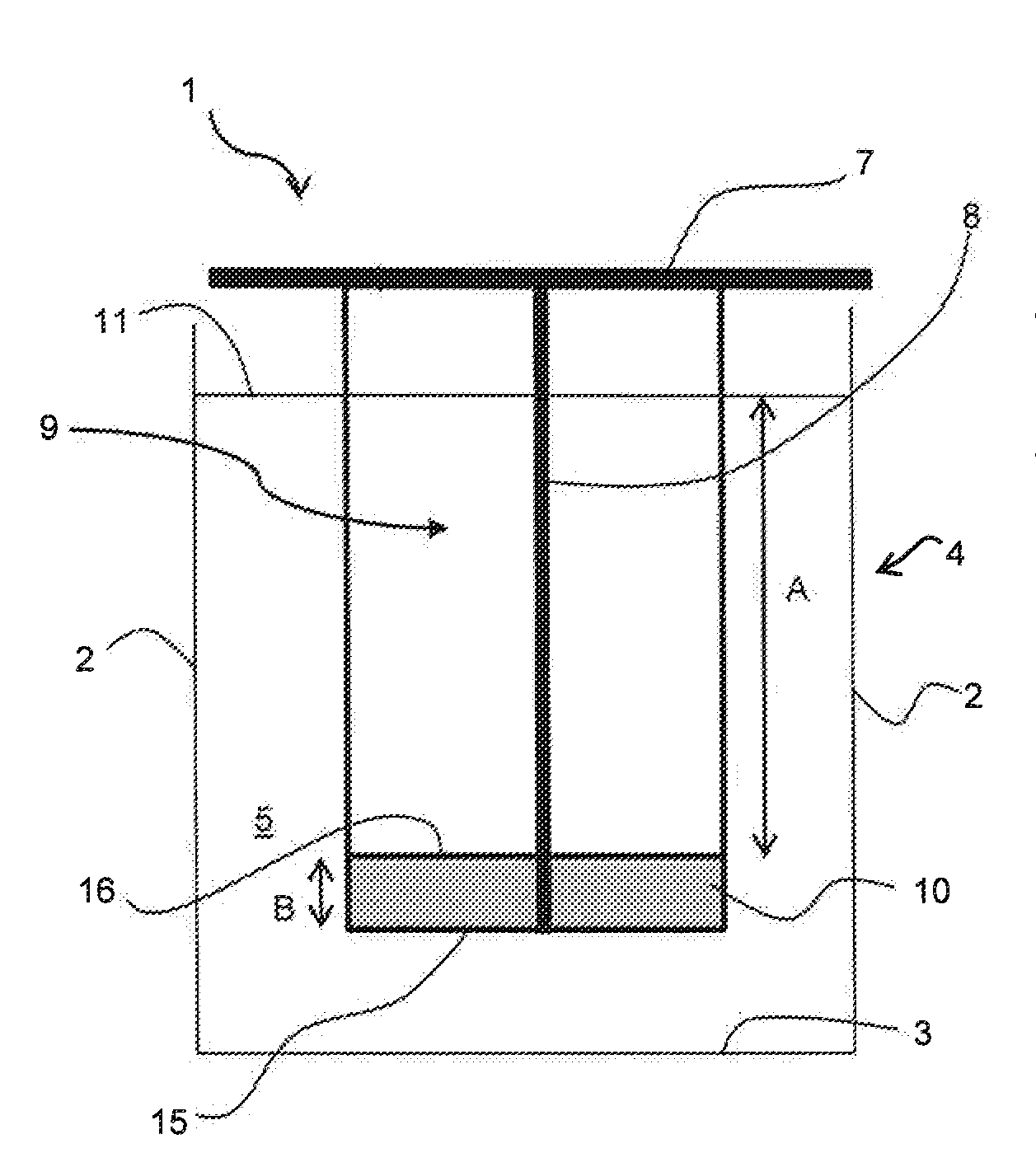

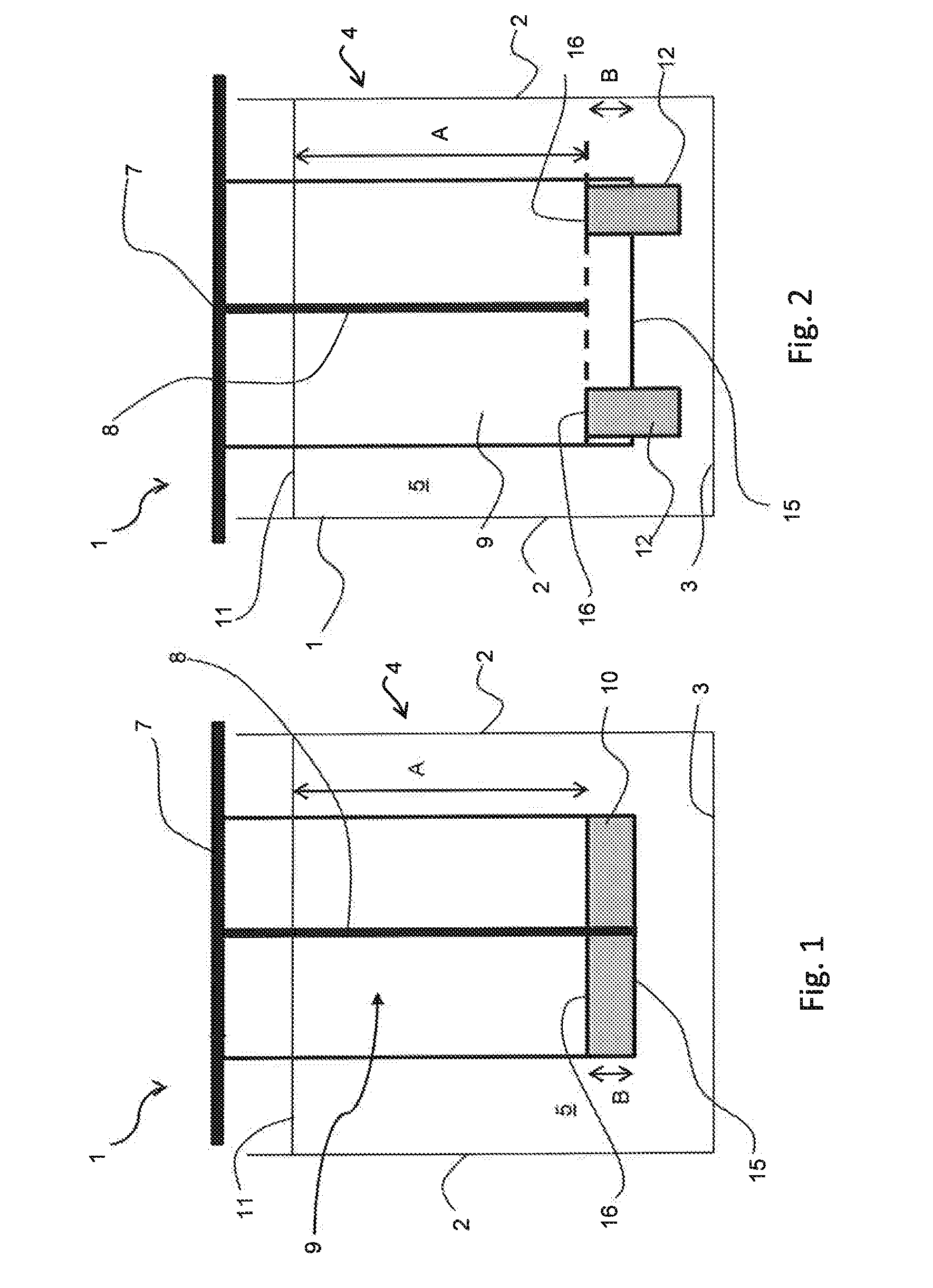

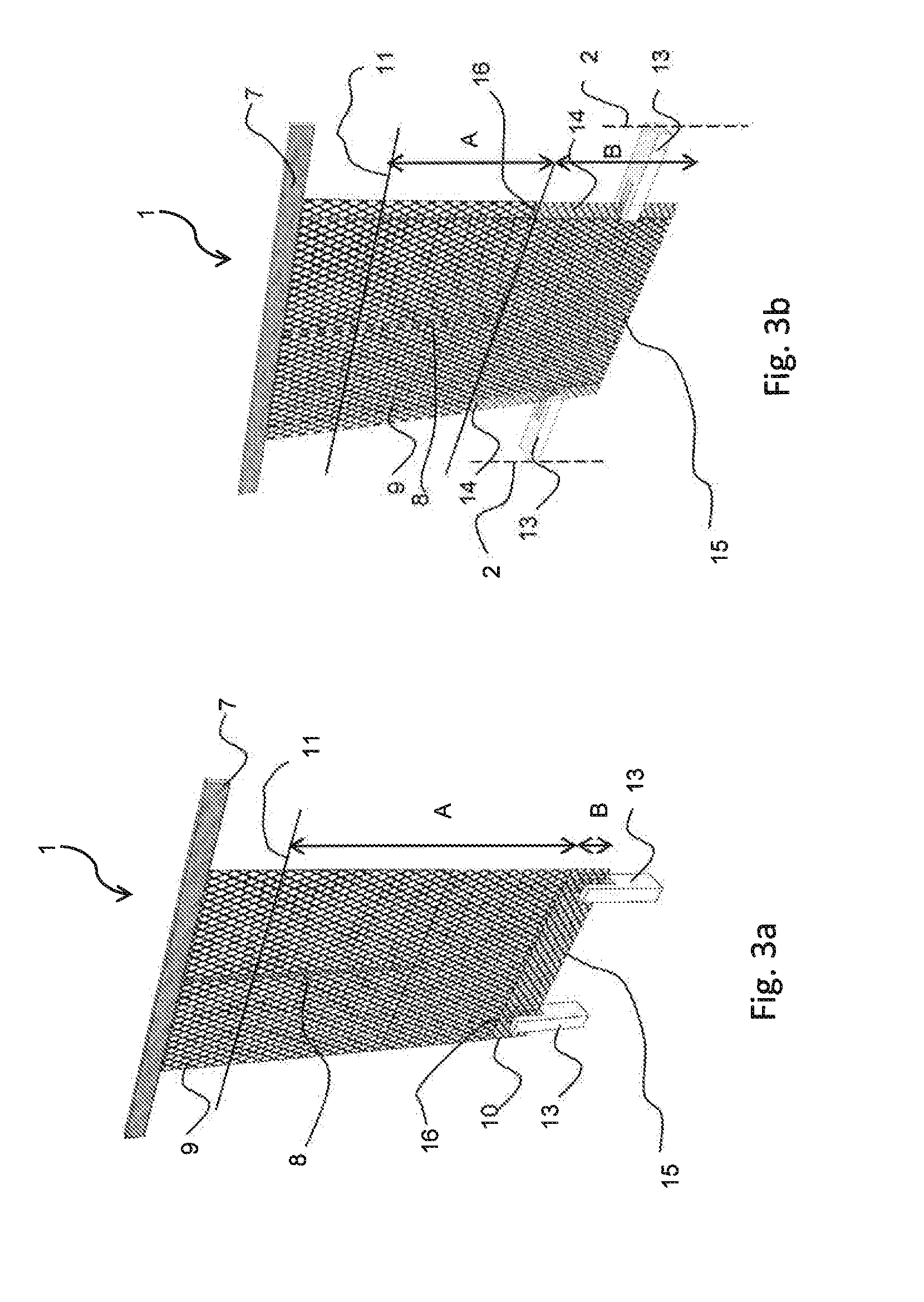

[0028]Reference will now be made in detail to the embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

[0029]FIGS. 1 and 2 shows an anode 1 for electrowinning of metals, such as copper in an electrolytic cell 2 having cell walls 3 and cell bottom 4 for holding an electrolyte 5. The anode comprises of a hanger bar 7 for supporting the anode on the conducting rod 8, which distributes the current to the anode, an anode body 9 having at least partly conductive structure allowing the penetration of the electrolyte and an electrocatalytic coating. According to the invention there is arranged a non-conductive element 10, 12, 14 in connection with the anode 1 at a distance A from the electrolyte surface level 11, when the distance A is arranged to be at an interval 0.3-2 meter. This depends on the size of the anode used. The non-conductive element 10, 12, 14 provides means for attaching the anode 1 inside the electrolytic cell 4, which is impo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com