Flexible heat transfer assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

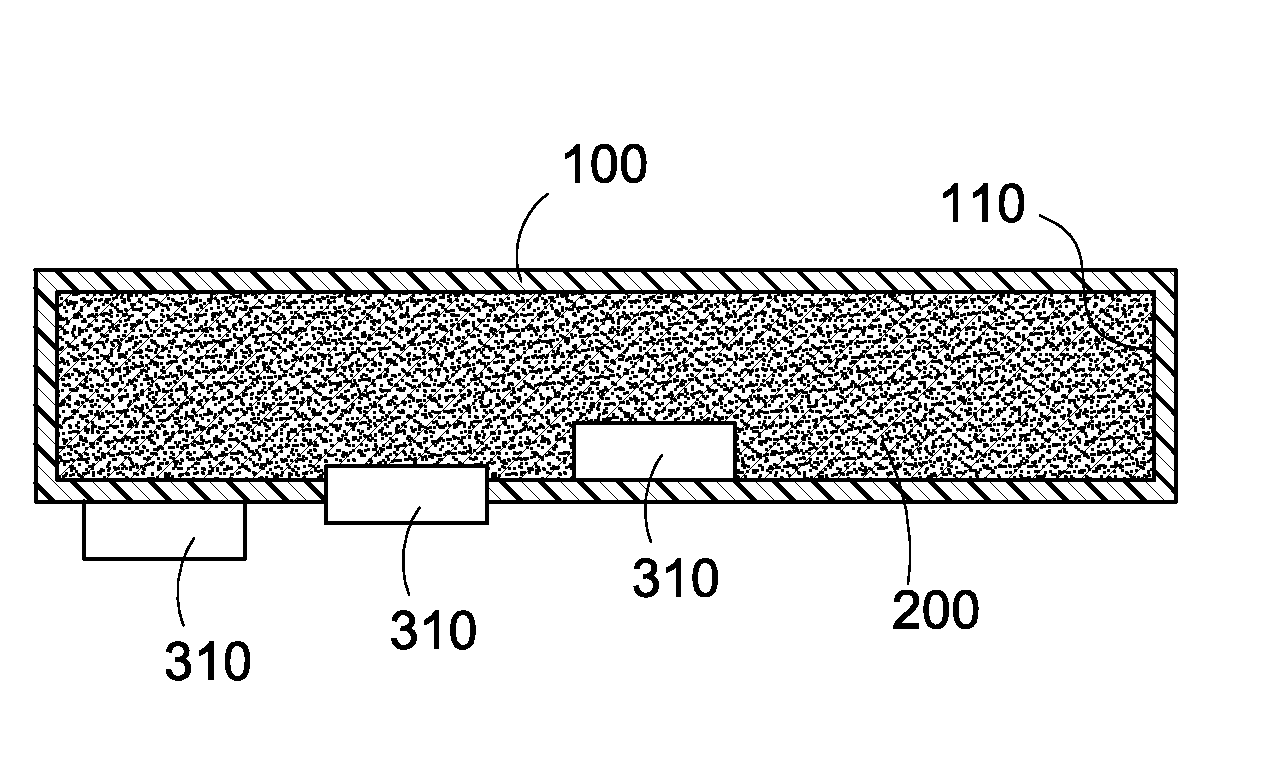

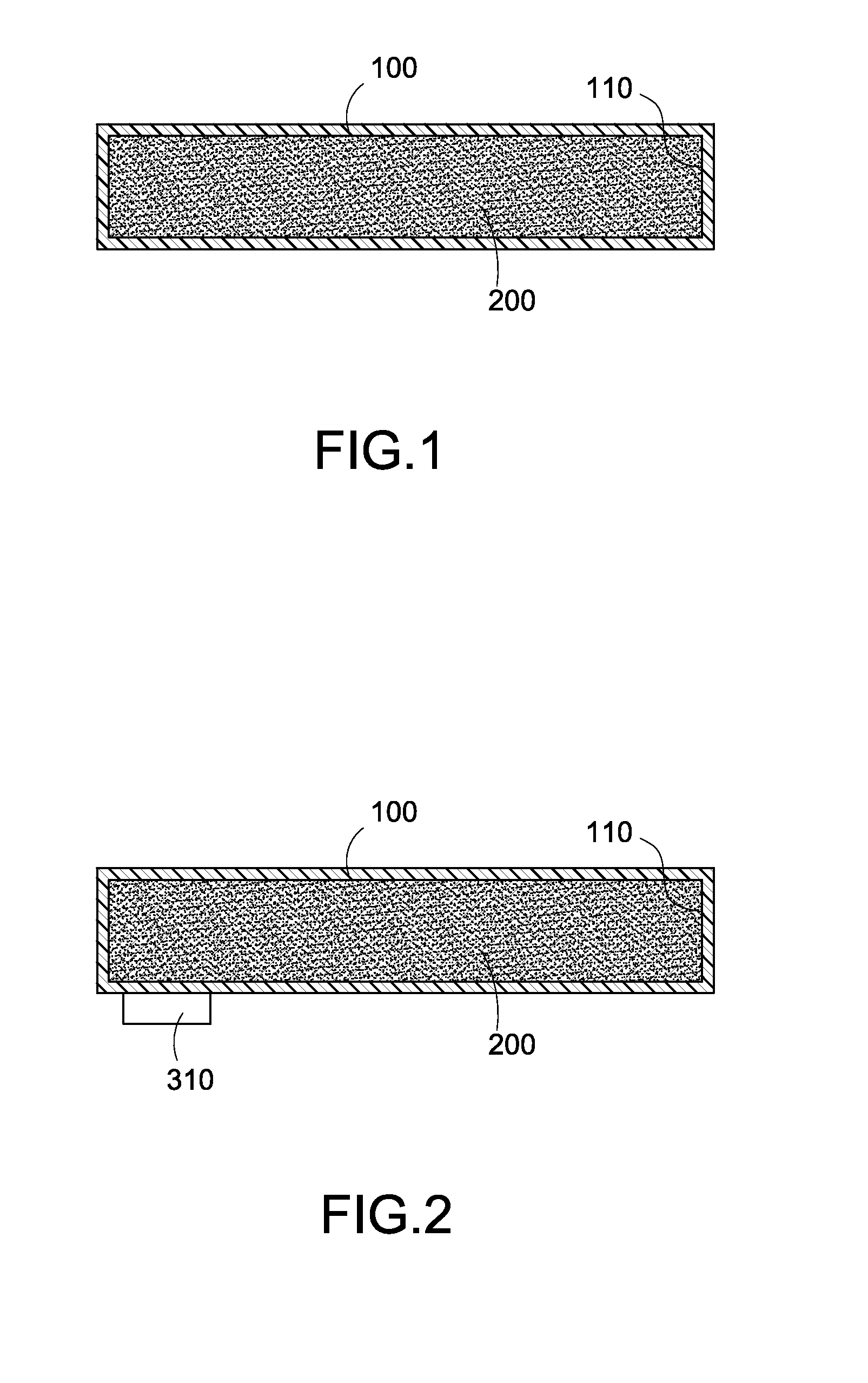

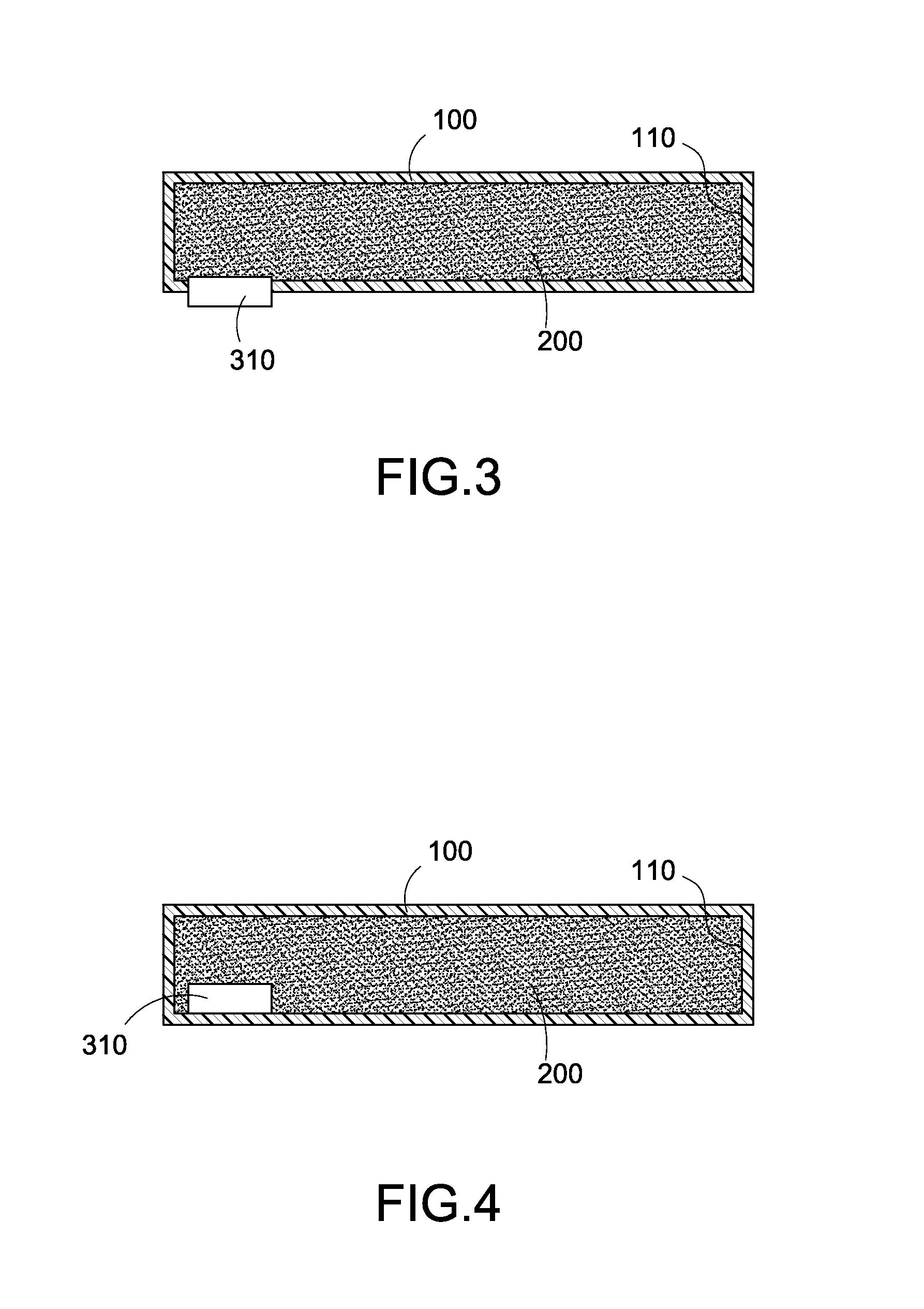

[0026]Referring to FIG. 1, it is provided the flexible heat transfer assembly according to the first embodiment of the present invention. The flexible heat transfer assembly comprises a covering layer 100 and a functional filler 200. The covering layer 100 surroundingly forms a sealed chamber 110. The functional filler 200 is filled in the sealed chamber 110.

[0027]The covering layer 100 is made of retractable material of elasticity, toughness and recoverability. The covering layer 100 preferably has a thickness ranging from 0.02 mm to 5 mm. The material of the covering layer 100 is preferably one of rubber, silica rubber, and resin (or called plastic). The rubber may be one of natural rubber and synthetic rubber. The resin may be one of ethylene acid resin, acrylic resin, organosilicon resin, urethane resin, polyethylene terephthalate (PET), and Polycarbonate (PC), in which the ethylene acid resin may be one of polyethylene (PE) and low density polyethylene (LDPE); the acrylic resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com