Light emitting microcapsule, method of preparing the same and OLED display device comprising the same

a technology of light-emitting microcapsules and display devices, which is applied in the field of display technology, can solve the problems of reducing the lightness of a phosphorescent oled, the phosphorescent material is more easily to suffer from a loss, so as to reduce the quenching probability of phosphorescent material, avoid phosphorescence losses, and the amount of phosphorescent material within

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

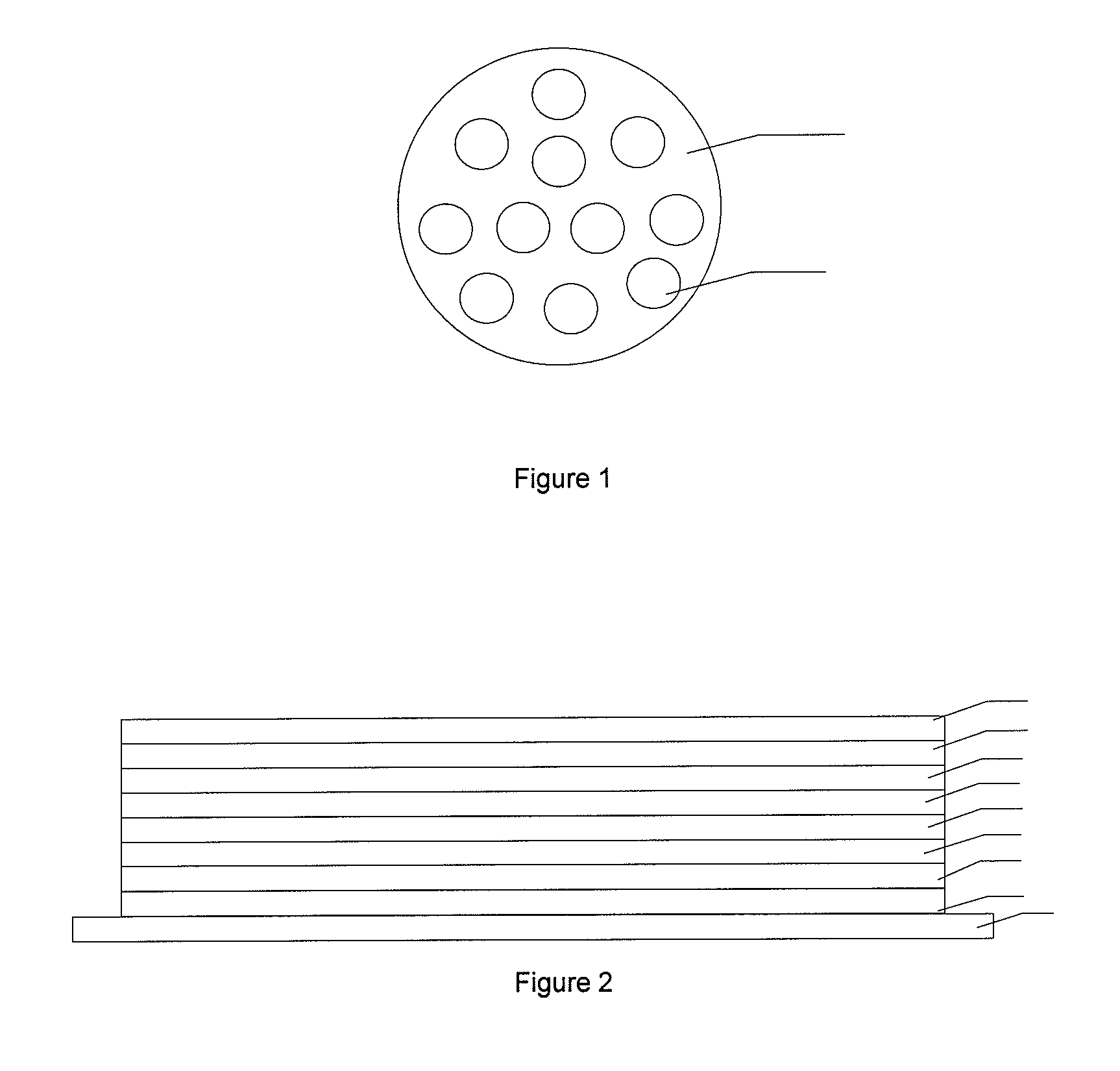

[0021]Embodiments of the present invention will be described in detail with reference to the accompanying figures, so that a person skilled in the art can get a better understanding of the technical solutions of the invention.

Preparation of Microcapsules

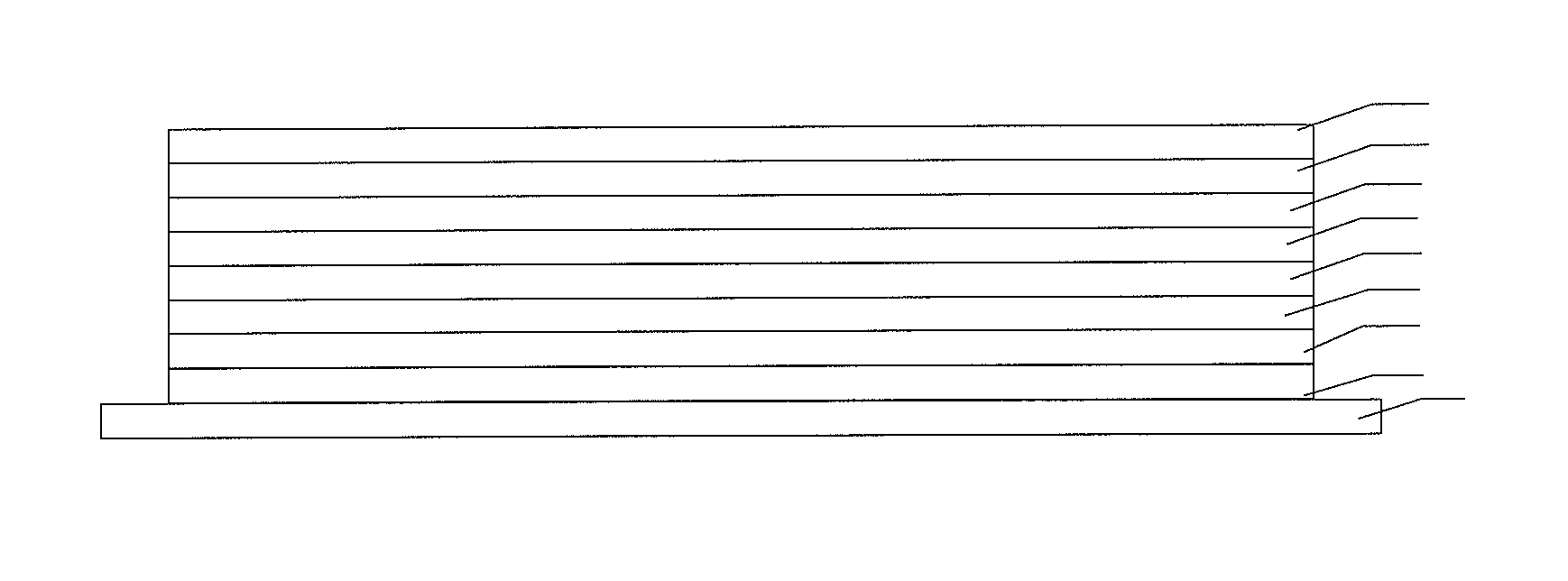

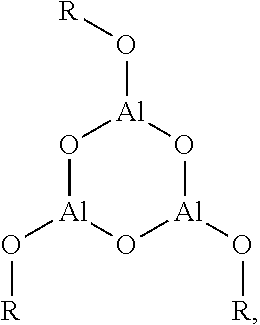

[0022]As shown in FIG. 1, this embodiment provides a microcapsule 1 comprising a wall material and a core material, wherein the core material is phosphorescent material 2 and the wall material is a wall material capable of encapsulating the phosphorescent material.

[0023]Said phosphorescent material 2 can be a complex of iridium, such as a green phosphorescent material of Ir(ppy)3, a blue phosphorescent material of FCNIr, a red phosphorescent material of Ir(pq)2acac and the like, with the molecular structures shown below:

[0024]It should be understood that any of the phosphorescent materials in the prior art can be used as a core material of the microcapsules.

[0025]Preferably, the phosphorescent material 2 has a particle size in a rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com