Method for combusting exhaust gas with oxygen feed line

a technology of exhaust gas and oxygen feed line, which is applied in the direction of combustion types, lighting and heating apparatus, incinerator apparatus, etc., can solve the problems of no longer usable exhaust gas during the conversion process of materials, and achieve the effect of reducing the vulnerability of the flaring system to failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

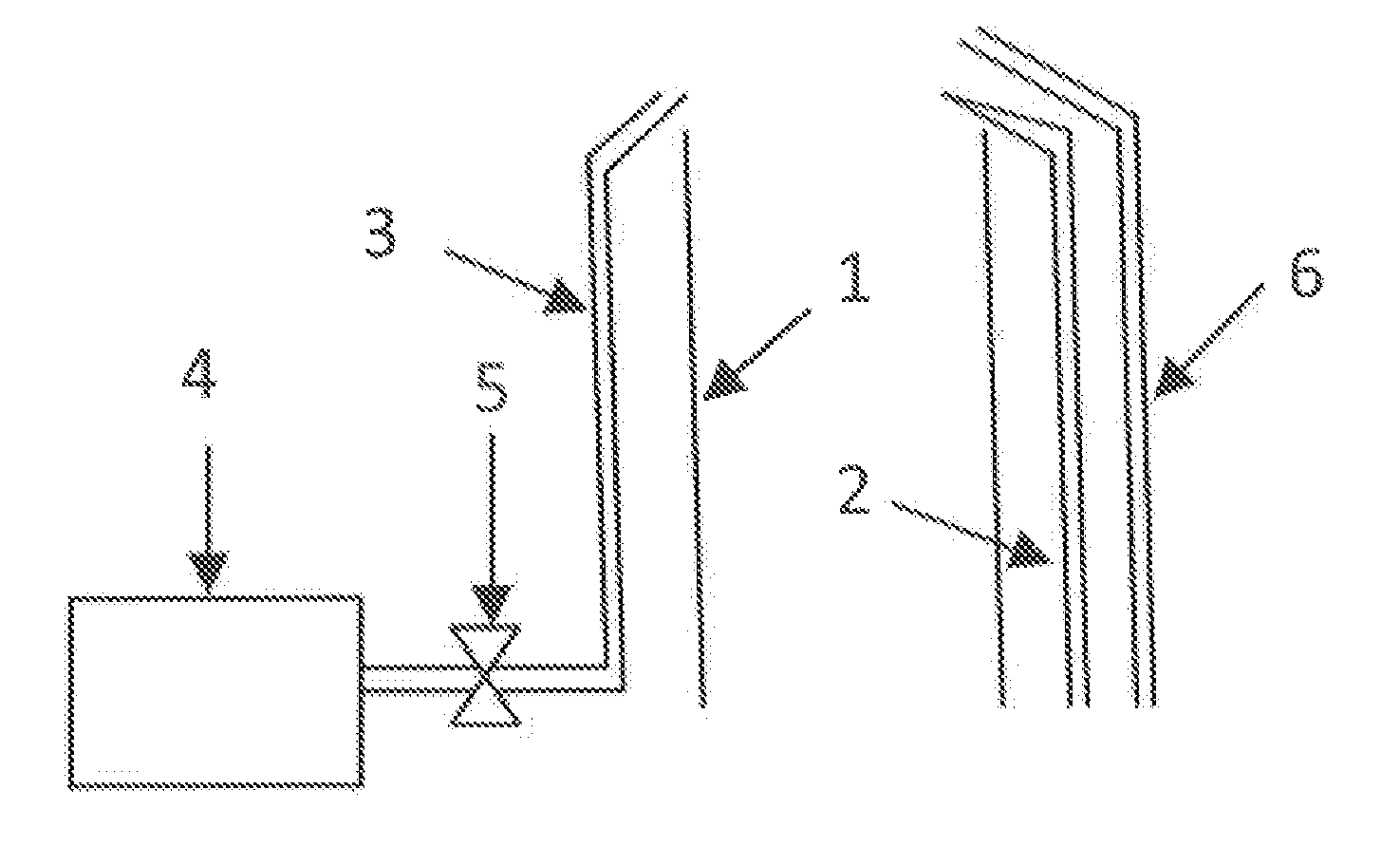

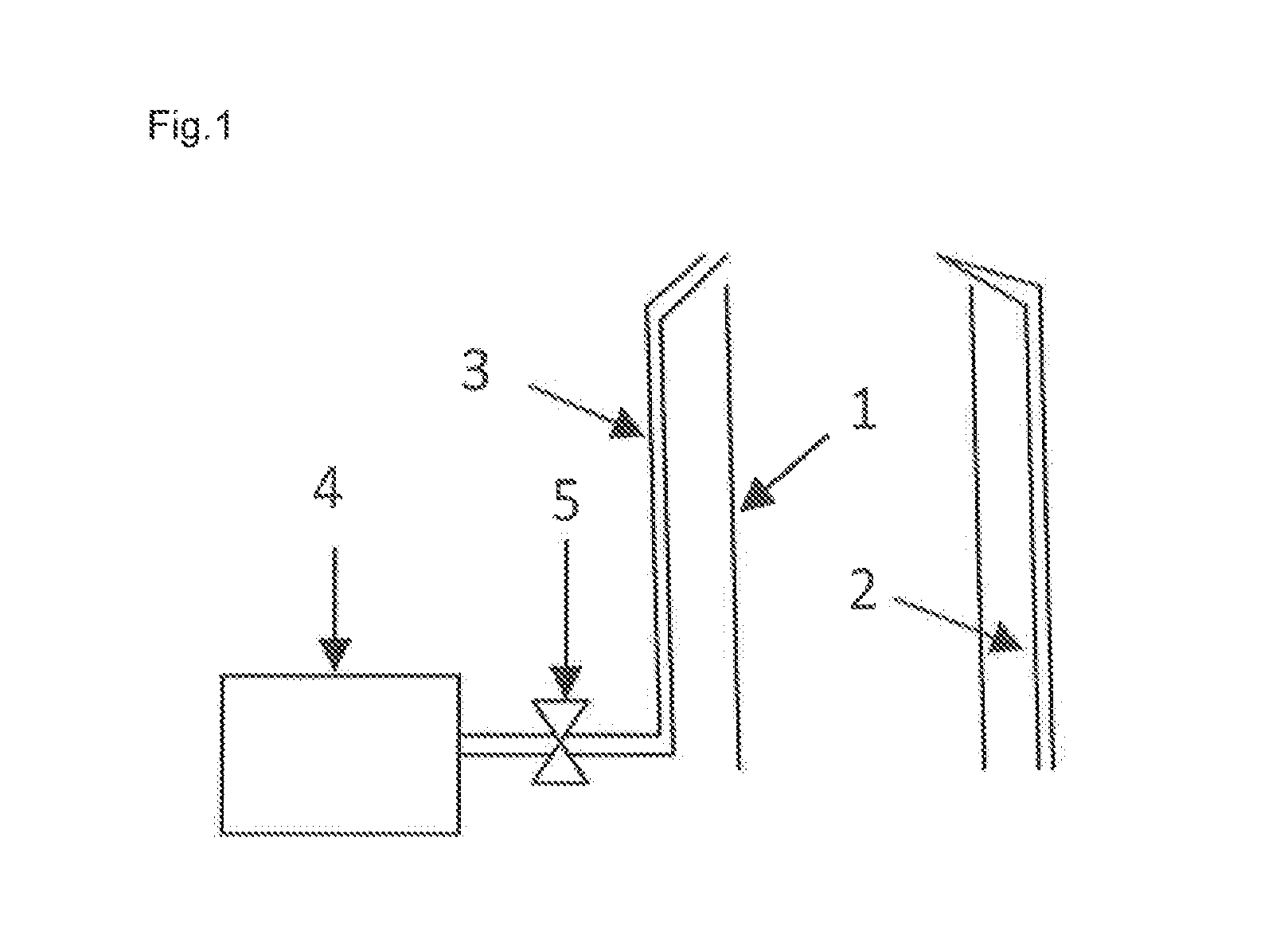

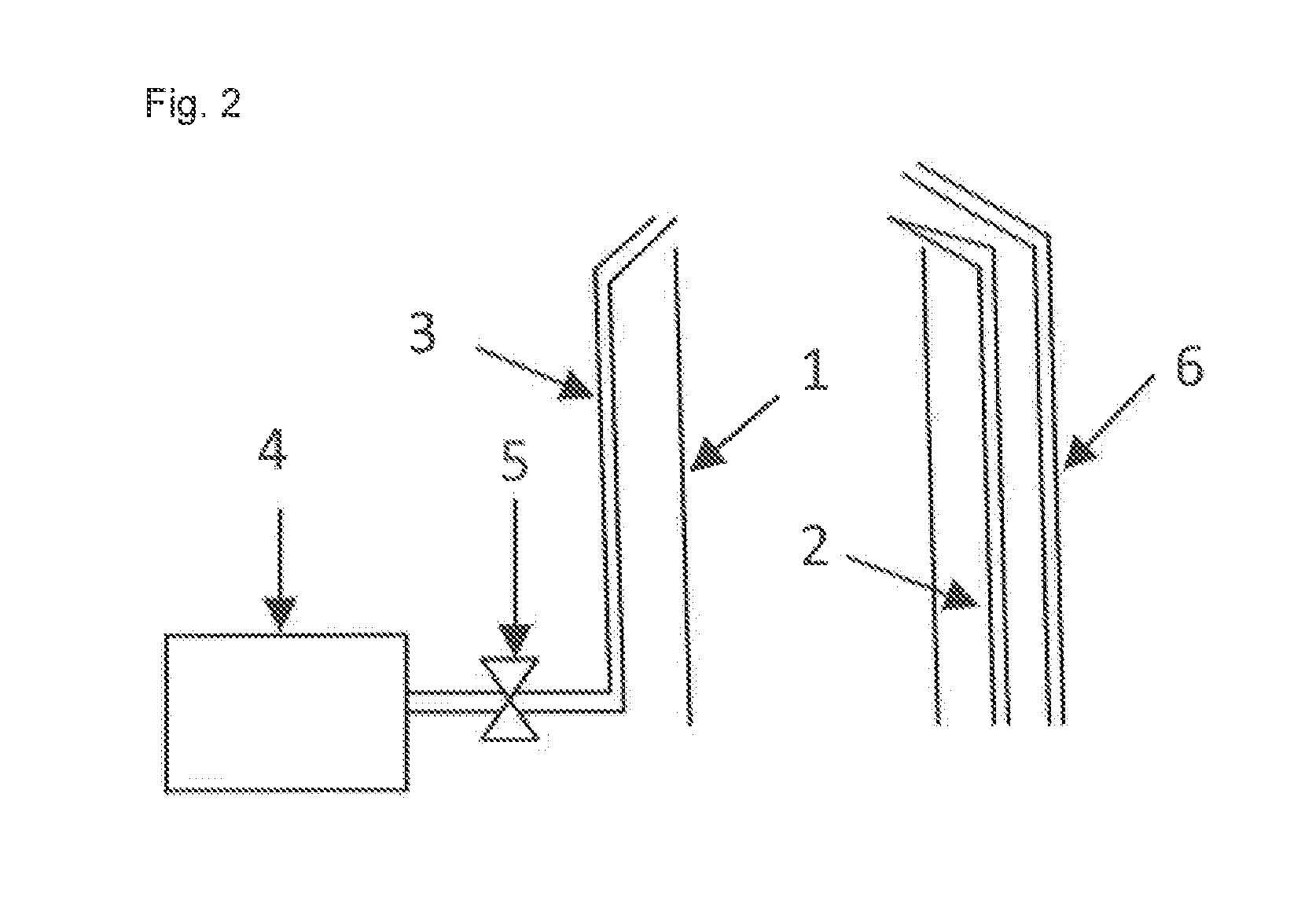

[0031]FIG. 1 presents a schematic view of a device according to the invention for combusting exhaust gases. The device consists of an exhaust pipe 1, an ignition device 2 and an oxygen feed line 3, which is connected with an oxygen tank 4. The exhaust gases, for example which come about in a refinery or in a chemical factory, exit from the exhaust pipe 1, and are ignited by the ignition device 2 with the formation of a flame.

[0032]An oxygen-containing gas, in particular oxygen-enriched air with an oxygen content exceeding 30% v / v, exceeding 50% v / v, exceeding 80% v / v or technically pure oxygen with an oxygen content exceeding 95% v / v or exceeding 99% v / v, is introduced into the flame through the oxygen line 3, wherein the oxygen is introduced from a liquid oxygen tank 4 by way of a valve 5. The valve 5 is used to release the fixed quantity of oxygen, and is designed as a shutoff valve. In addition, it is easier to provide oxygen in a tank system than to generate steam, in particular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com