Cartridge-based 3D printing system

a 3d printing and printer technology, applied in the field of cartridge-based 3d printing system, can solve the problems of variable build quality, low cost printers with poor resolution, and high cost, and achieve the effects of high price, high quality, and high printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

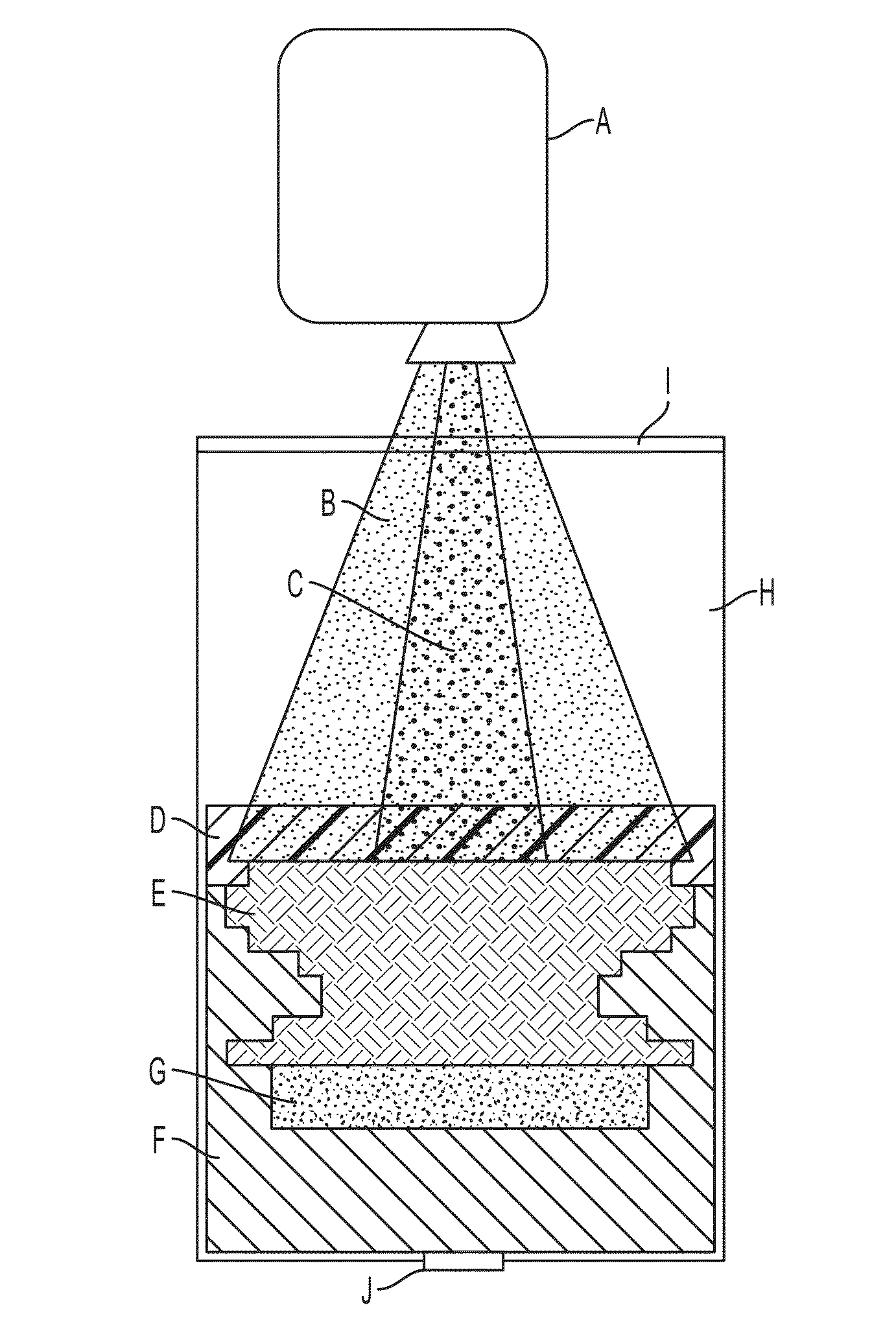

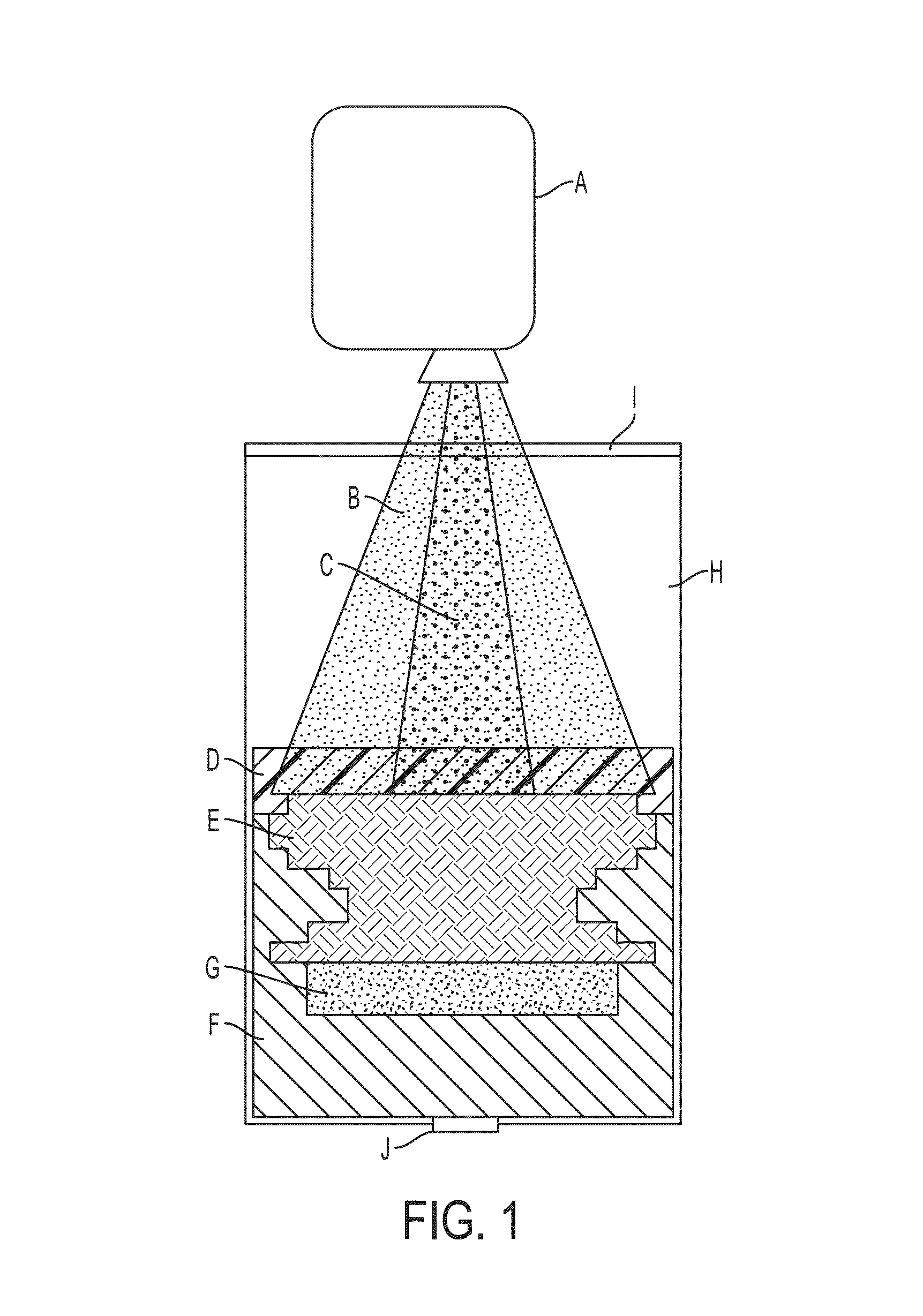

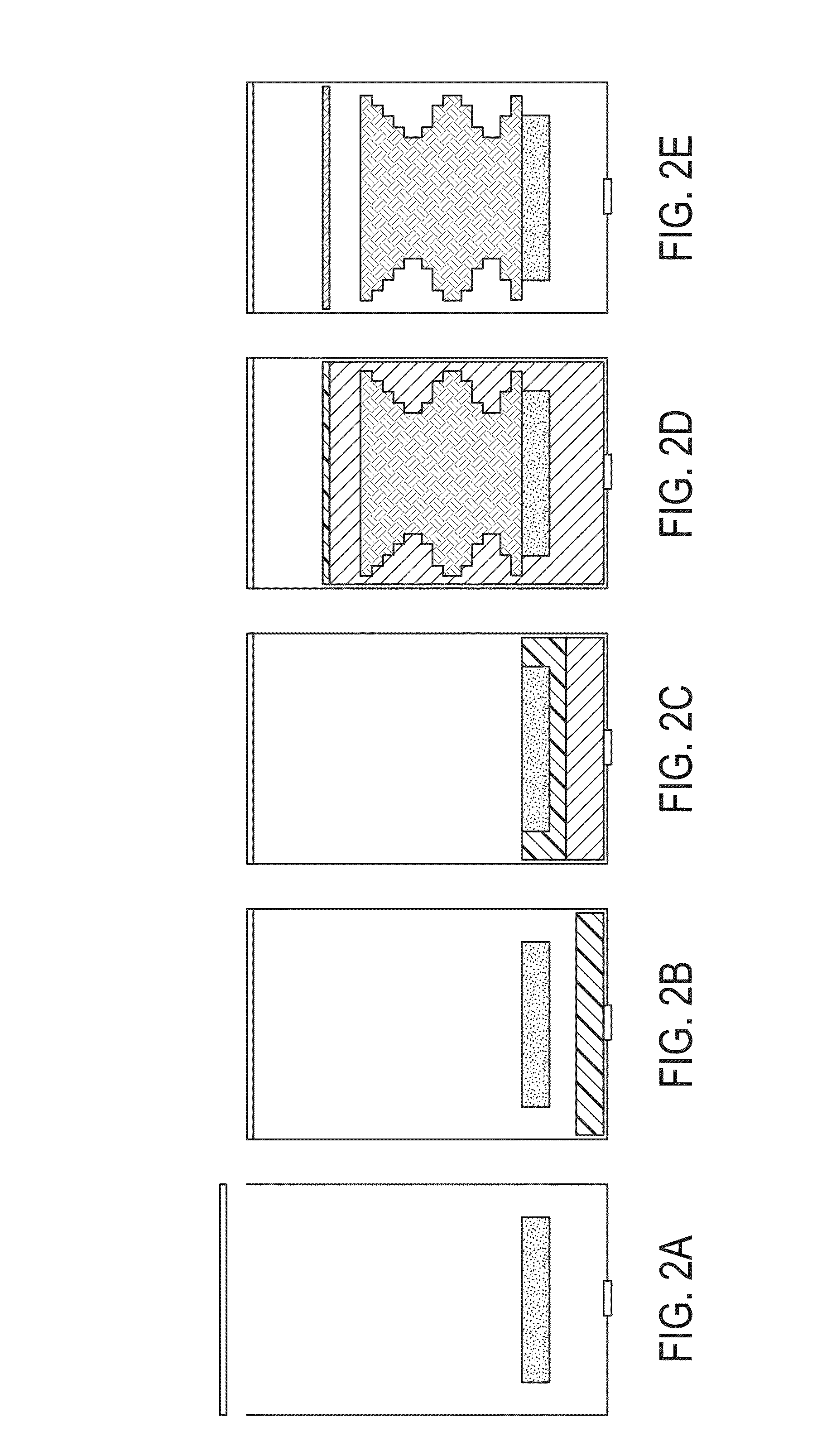

[0029]An embodiment of the claimed invention is directed to a 3D printing system (“system”). The system directs projected light at tunable wavelengths (“light source”) to cure a polymer resin from monomers or oligomers (“resin”) which is floating on a higher density liquid platform (“Z-fluid”) in which the curing (“reaction”) occurs within a prepackaged vessel (“cartridge”) which facilitates the layer which is printed at any given time. In a further embodiment, the resin can be packaged, sealed and sold within the cartridge. Cartridges of different sizes and dimensions contain different amounts of different colored materials. This allows users to rapidly select from among many combinations when ordering cartridges and easily switch materials, colors, sizes between successive print jobs without a costly system wide resin purge. One or more cartridges are loaded into the system, which allows for quick and convenient Z-fluid manipulation and the printing of the part within the cartridg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com