Corrosion resistant article and methods of making

a technology of corrosion resistance and articles, applied in the field of nanostructured ferritic alloys, can solve the problems of low strength, low to intermediate strength, and poor corrosion resistance of duplex steels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0044]The following example illustrates the method, materials and results, in accordance with specific embodiments, and as such should not be construed as imposing limitations upon the claims. All components are commercially available from common chemical suppliers.

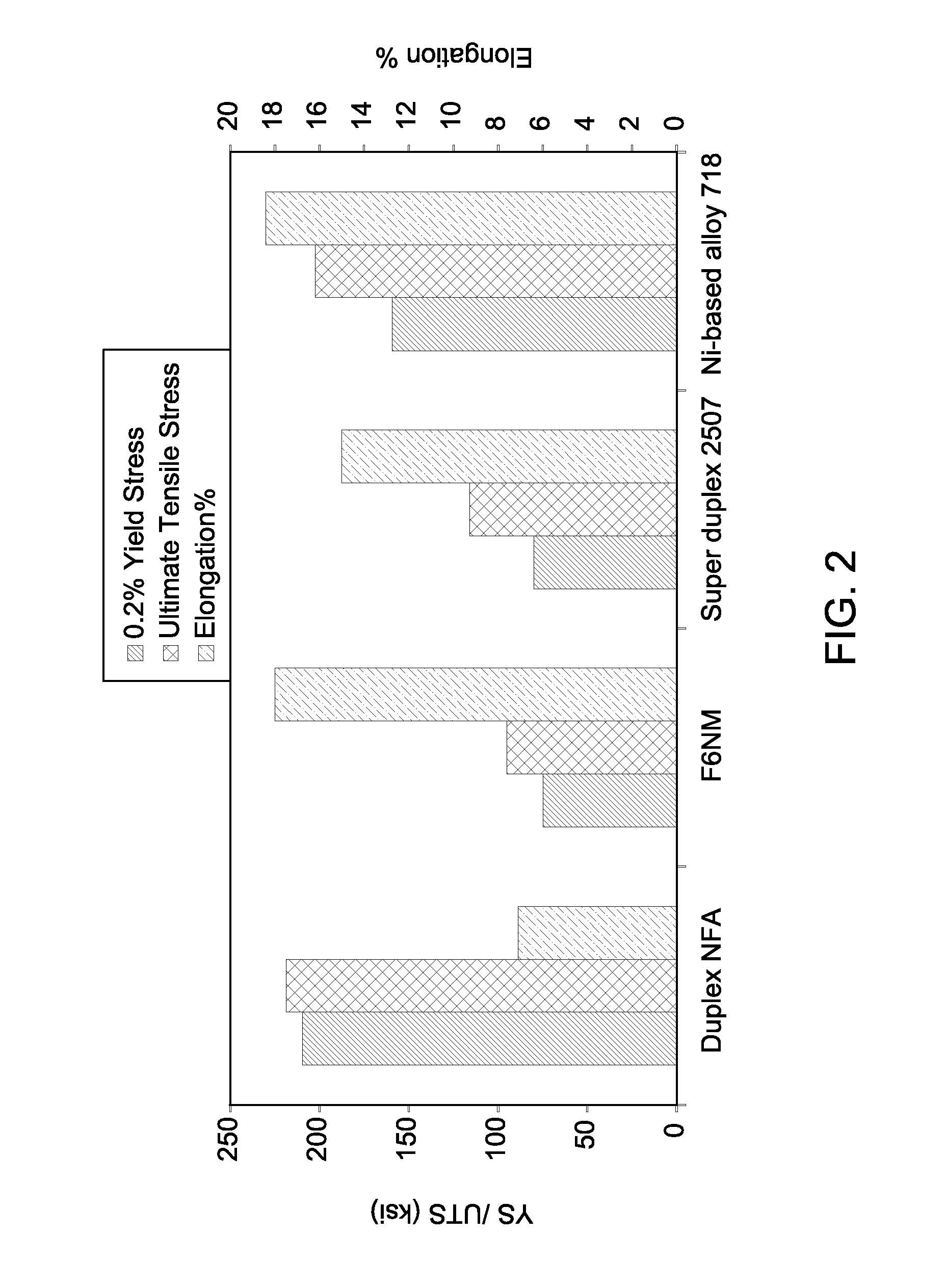

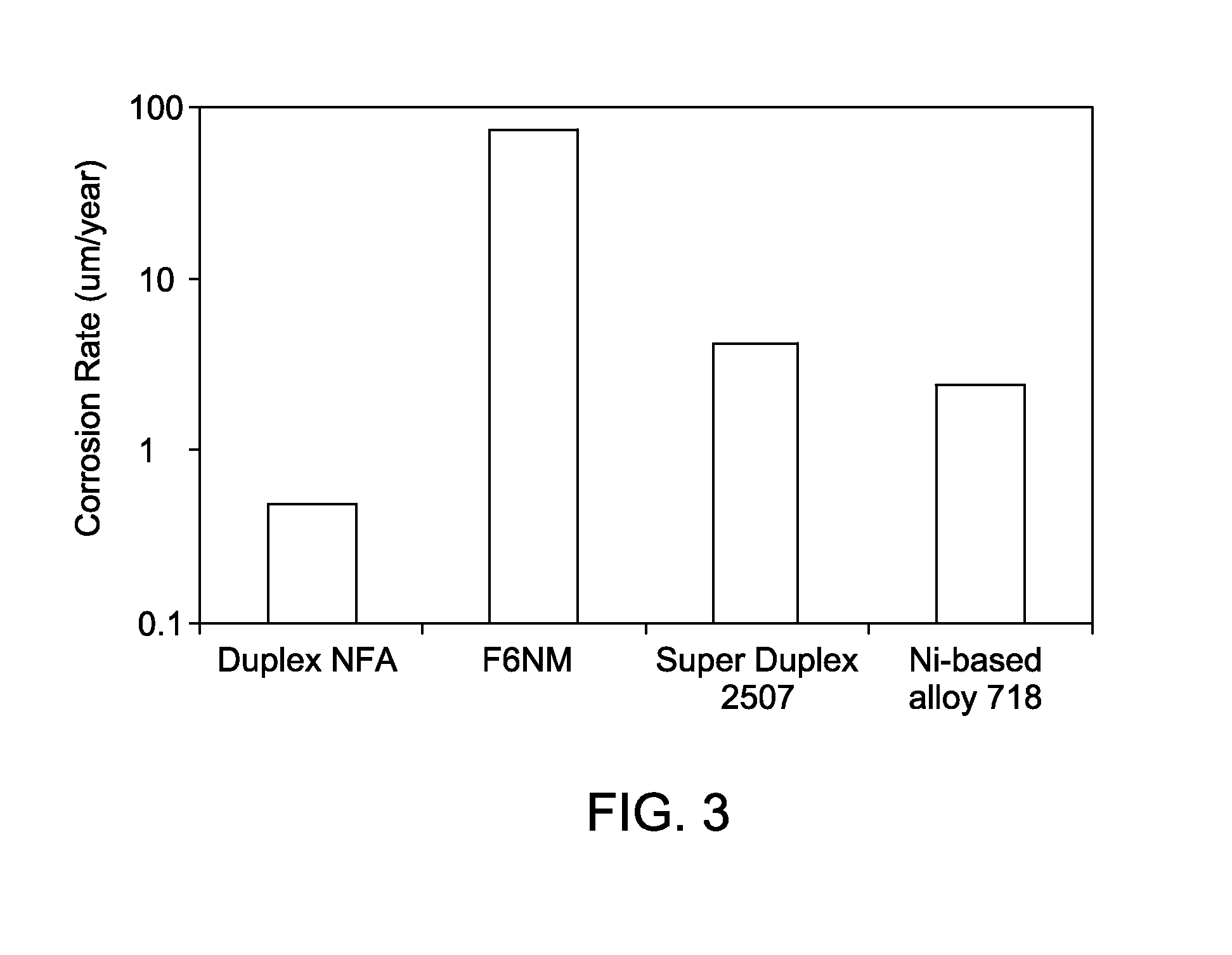

[0045]In one example method of preparation, pre-alloyed steel (Fe—Cr) powders doped with elemental metal powders (Cr, Mo, Ni, W, Ti) and iron nitride powder as necessary to match the nominal composition of the desired duplex NFA were taken as starting materials and mixed with Y2O3 powder. Nominal composition of the desired duplex NFA in this example was Fe-25Cr-3.5Mo-7Ni-0.25N-0.75W-0.4Ti-0.25Y2O3. Alternatively, pre-alloyed powders containing a mixture of 3 or more elements selected from Fe, Cr, Mo, Ni, W, and Ti may also be used as starting powders. Powders were mixed with 420 stainless steel balls (˜4.5 mm in diameter) with a 10:1 ratio and milled in a high energy attrition mill for about 20 hours in an argon environme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com