Brush for cosmetic implements and manufacturing method of the same

a technology for cosmetic implements and brushes, which is applied in the direction of packaging foodstuffs, packaging goods, transportation and packaging, etc. it can solve the problems of uneven length of bristles (tip parts), inconvenient user application of mascara to eyelashes, and additional problems such as increasing the radius of support members, so as to achieve convenient formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

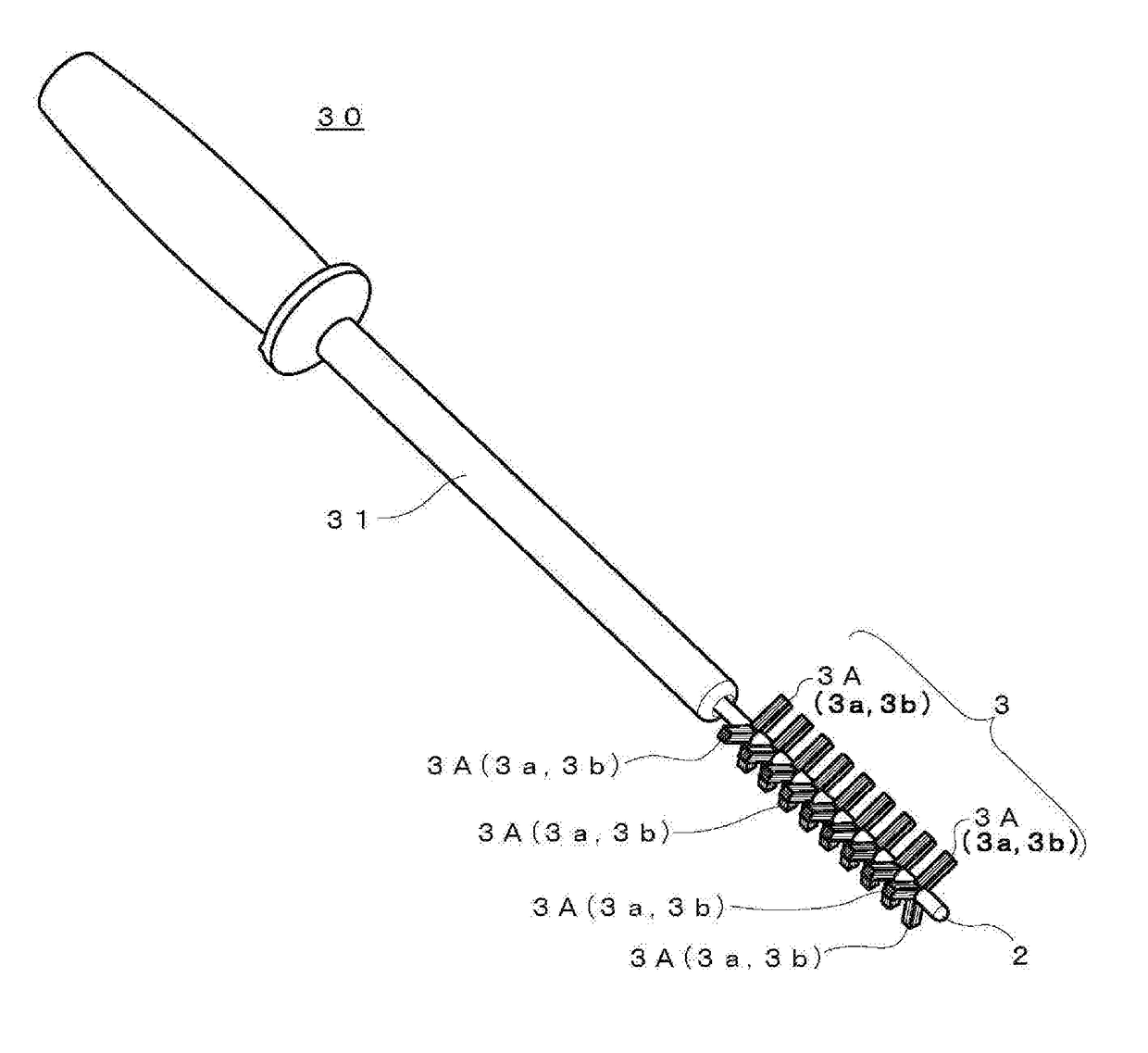

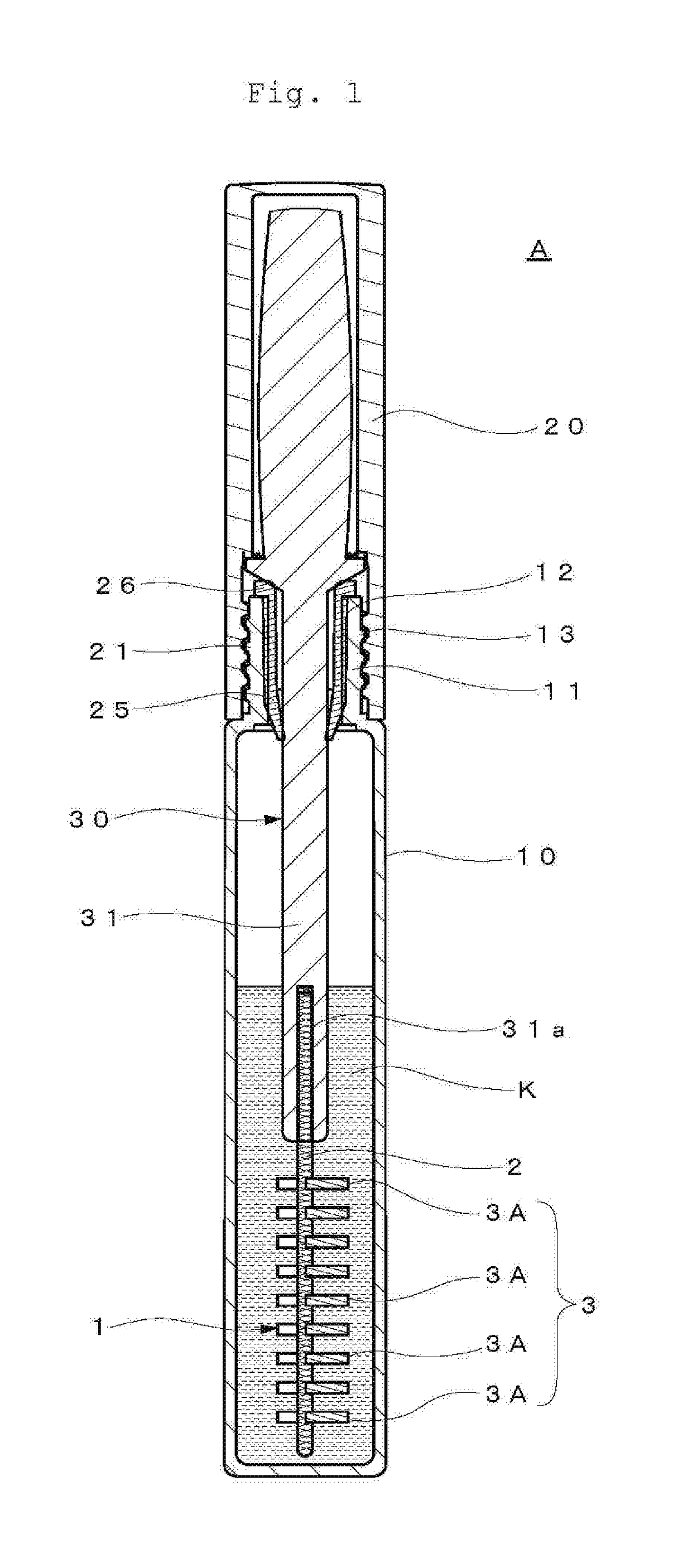

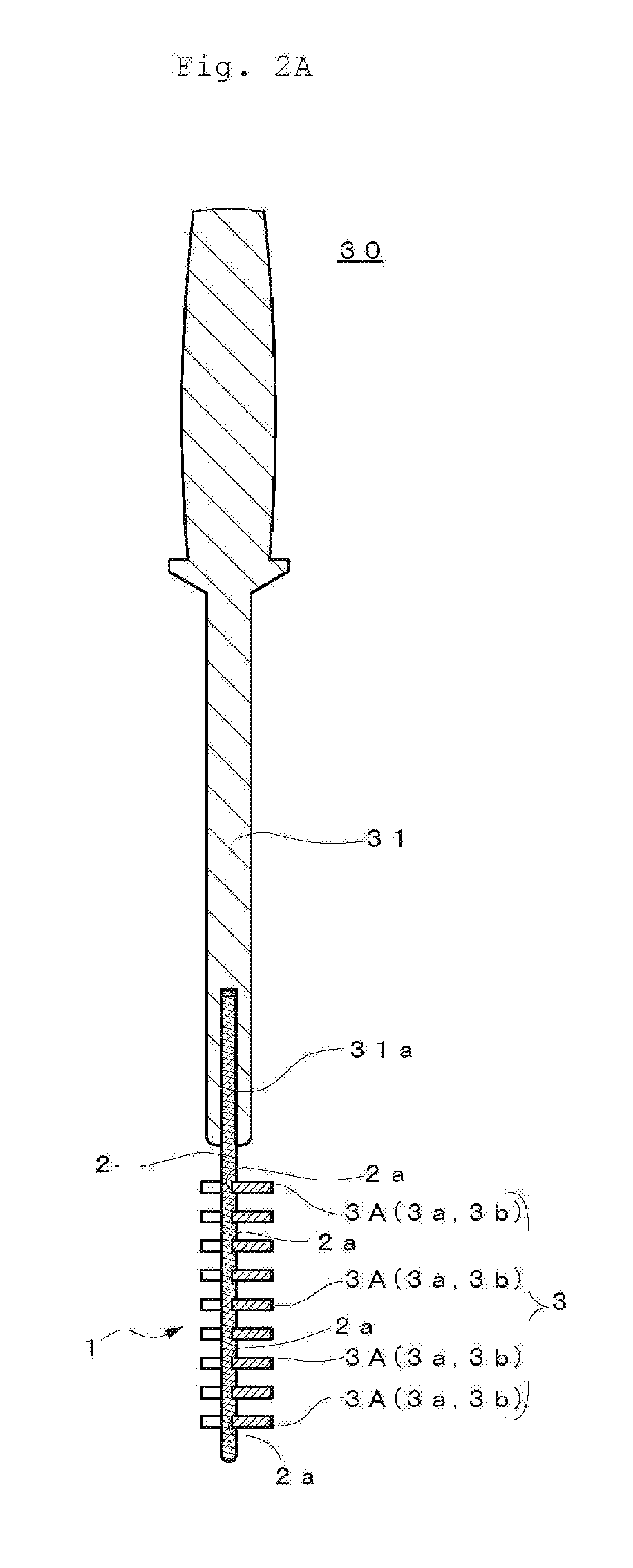

[0037]Hereinafter, an explanation will be made of an embodiment of the present invention with reference to the drawings FIGS. 1 through 5. Cosmetic implements to which the brush according to the present invention is utilized are such as eye-liners, mascaras, nail polish, lipsticks, hair dyes. In the present embodiments, a mascara having fluidity will be described as an example. A cosmetic implement A includes a container 10 containing a coating liquid K, a cap 20 threadedly engaging with the container 10, and applicator 30 provided with a brush part 3 immersed in the coating liquid K in the container 10.

[0038]The container 10 is formed in a bottomed cylinder shape having a neck portion 11 and contains a prescribed amount of the coating liquid K of mascara with fluidity. The coating liquid includes, as disclosed in Japanese Patent No. 5791424, a viscosity modifier 0.1 to 2 wt %, a film-forming agent 0.5 to 30 wt %, a pigment having an average diameter 1 mm or larger 0.5 to 30 wt %, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com