Pyrolysis systems

a technology of pyrolysis systems and pyrolysis equipment, which is applied in the direction of combustion types, machines/engines, lighting and heating apparatuses, etc., can solve the problems of increasing disposal problems of waste materials, wastes are generally abandoned, and refuse and toxic waste are often burned, so as to reduce the discharge of flue gas, enhance the viability of use, and increase the energy yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

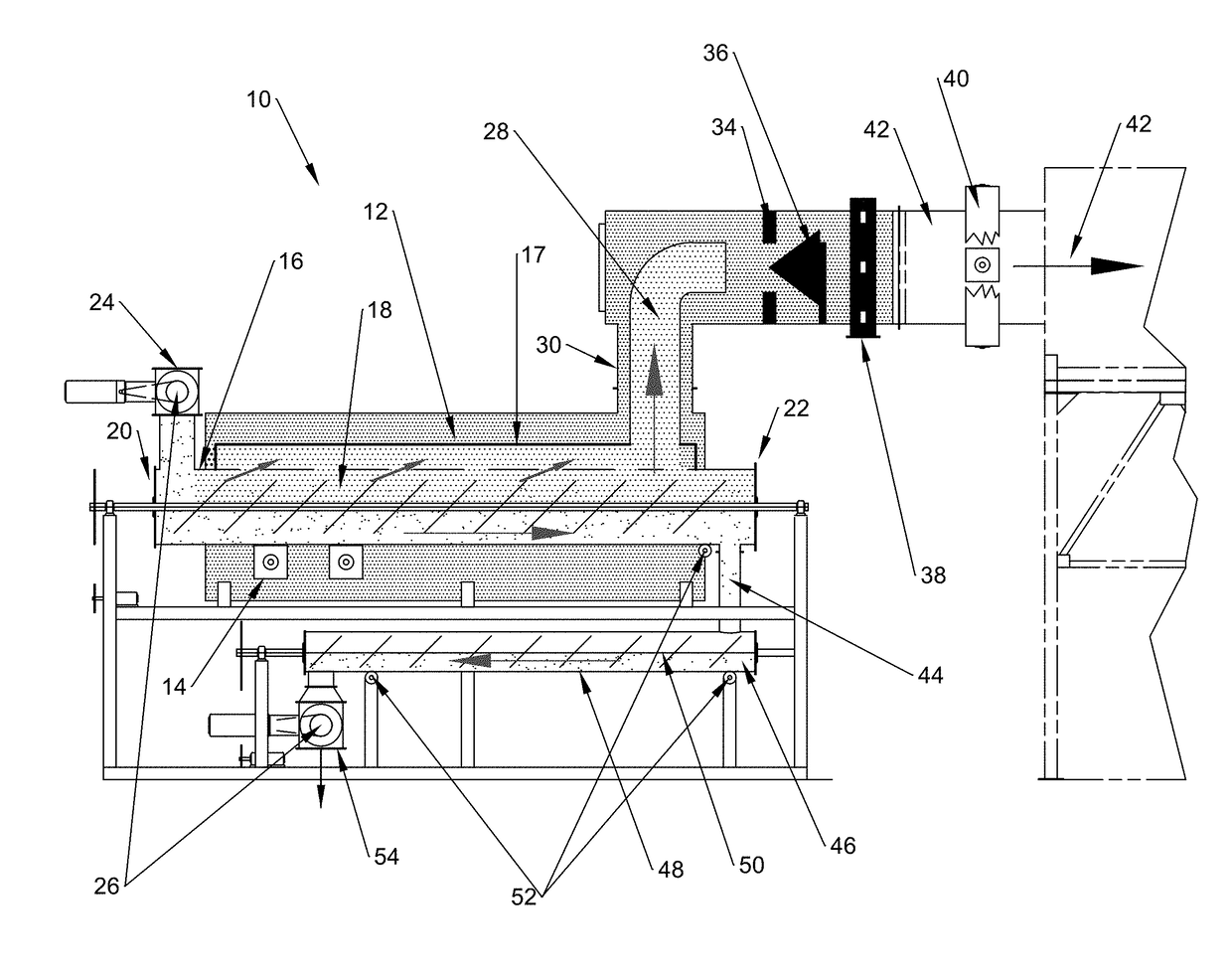

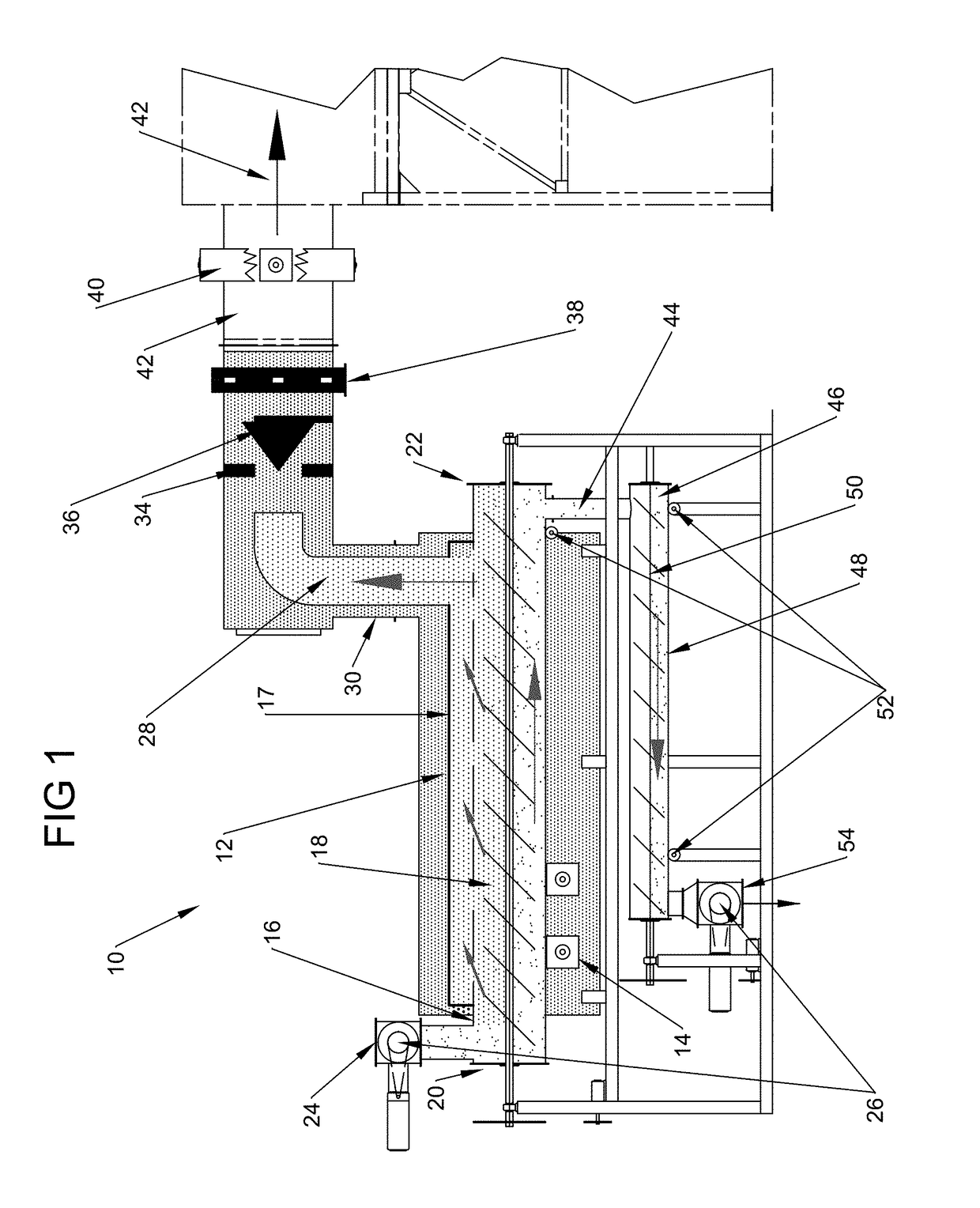

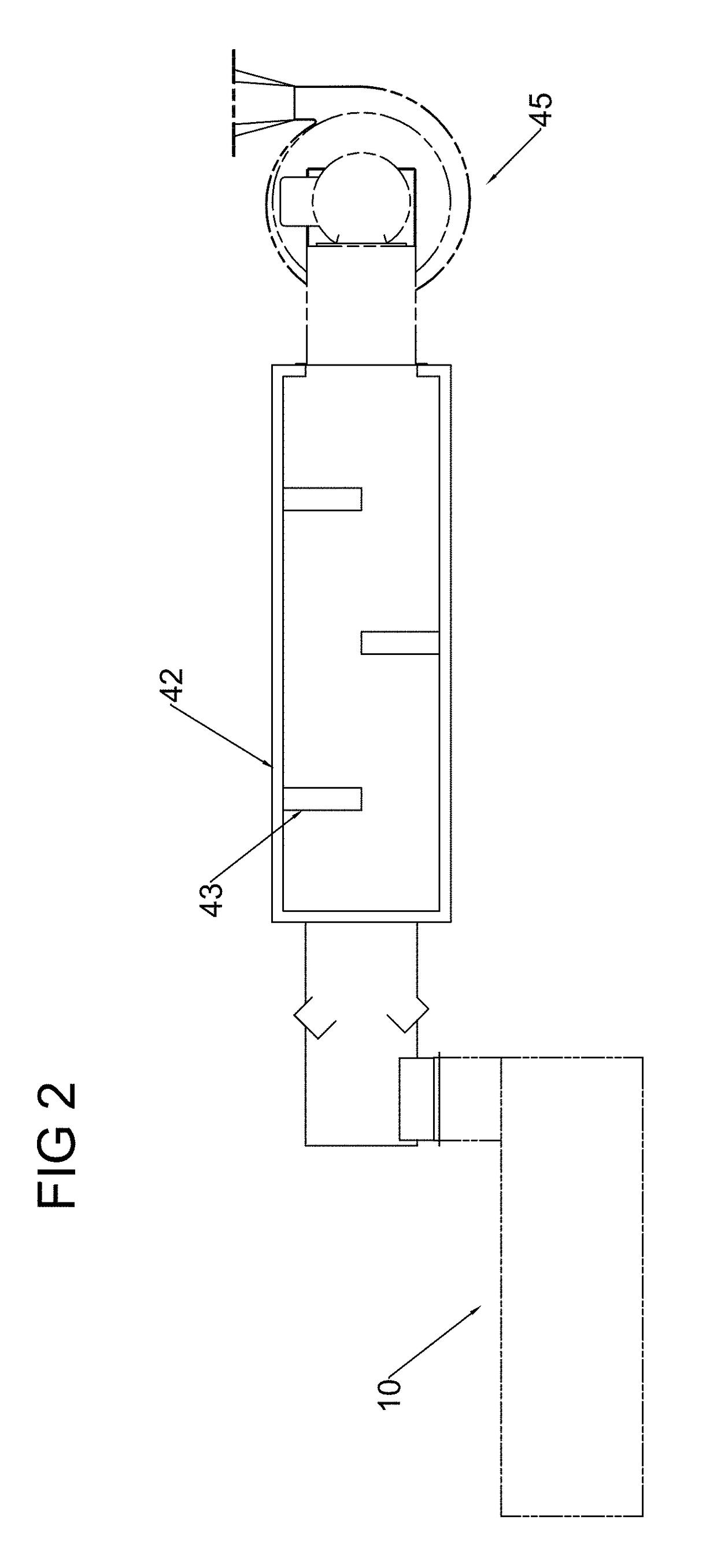

[0020]A pyrolysis unit 10 is shown in FIG. 1. Pyrolysis unit 10 may be used to perform the initial pyrolysis step in a pyrolysis system that includes a thermal oxidizer unit and stack unit (not shown.) As noted above, the pyrolysis unit routes syngas discharge in a manner that reduces maintenance of the unit, routes flue gases in a manner that recovers their heat and eliminates discharge of flue gas to the environment, and includes other features which enhance the commercial viability of the pyrolysis system.

[0021]The pyrolysis unit 10 includes a combustion chamber 12, which is made from materials capable of withstanding temperatures of 1200-2600° F. Burners 14 are positioned within the combustion chamber. These burners may be natural gas or propane-fired and are adapted to generate and supply hot combustion gases into the combustion chamber. While two burners are illustrated, more or fewer could be provided.

[0022]A main retort 16 is disposed within the combustion chamber 12. Pyroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com