Corrosion inhibitor composition for magnesium or magnesium alloys

a technology of corrosion inhibitors and compositions, which is applied in the direction of electrolytic coatings, surface reaction electrolytic coatings, anodisation, etc., can solve the problems of reducing affecting the corrosion resistance of magnesium alloys, so as to inhibit the corrosion of such metals and lessen the environmental concern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

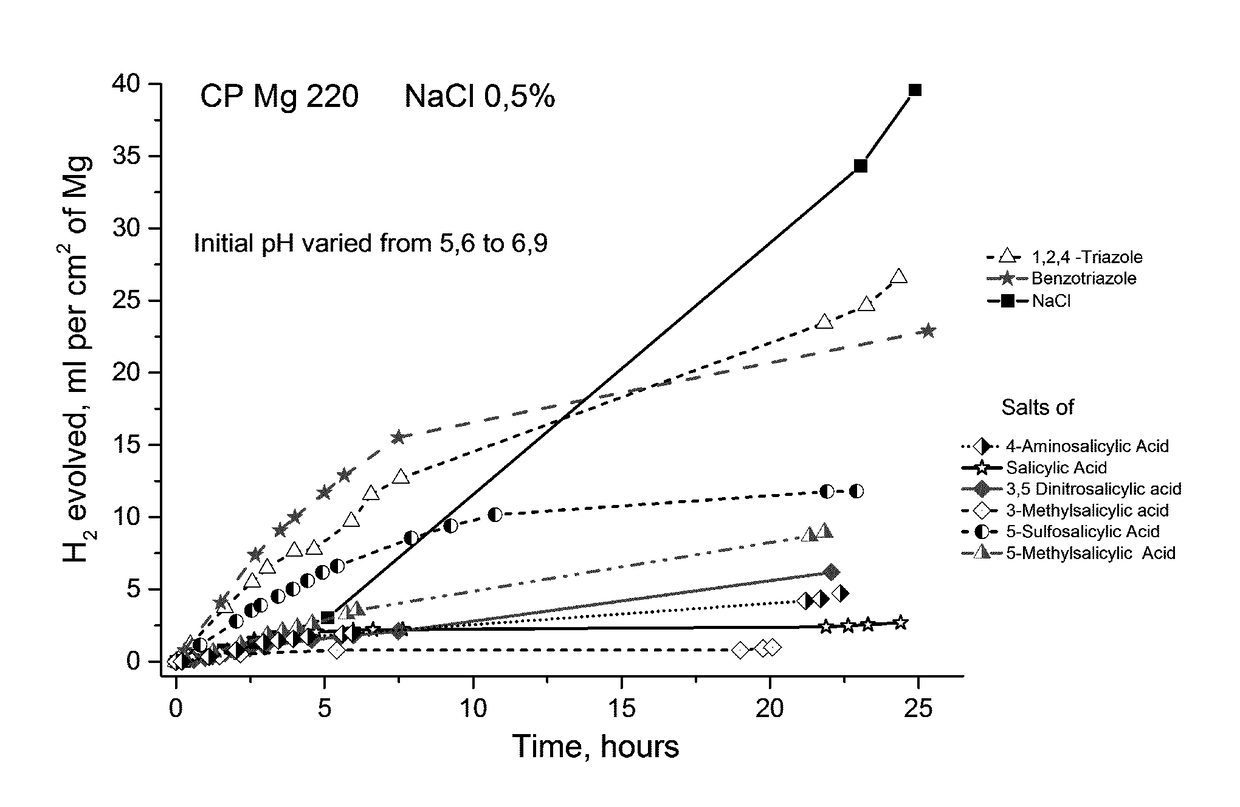

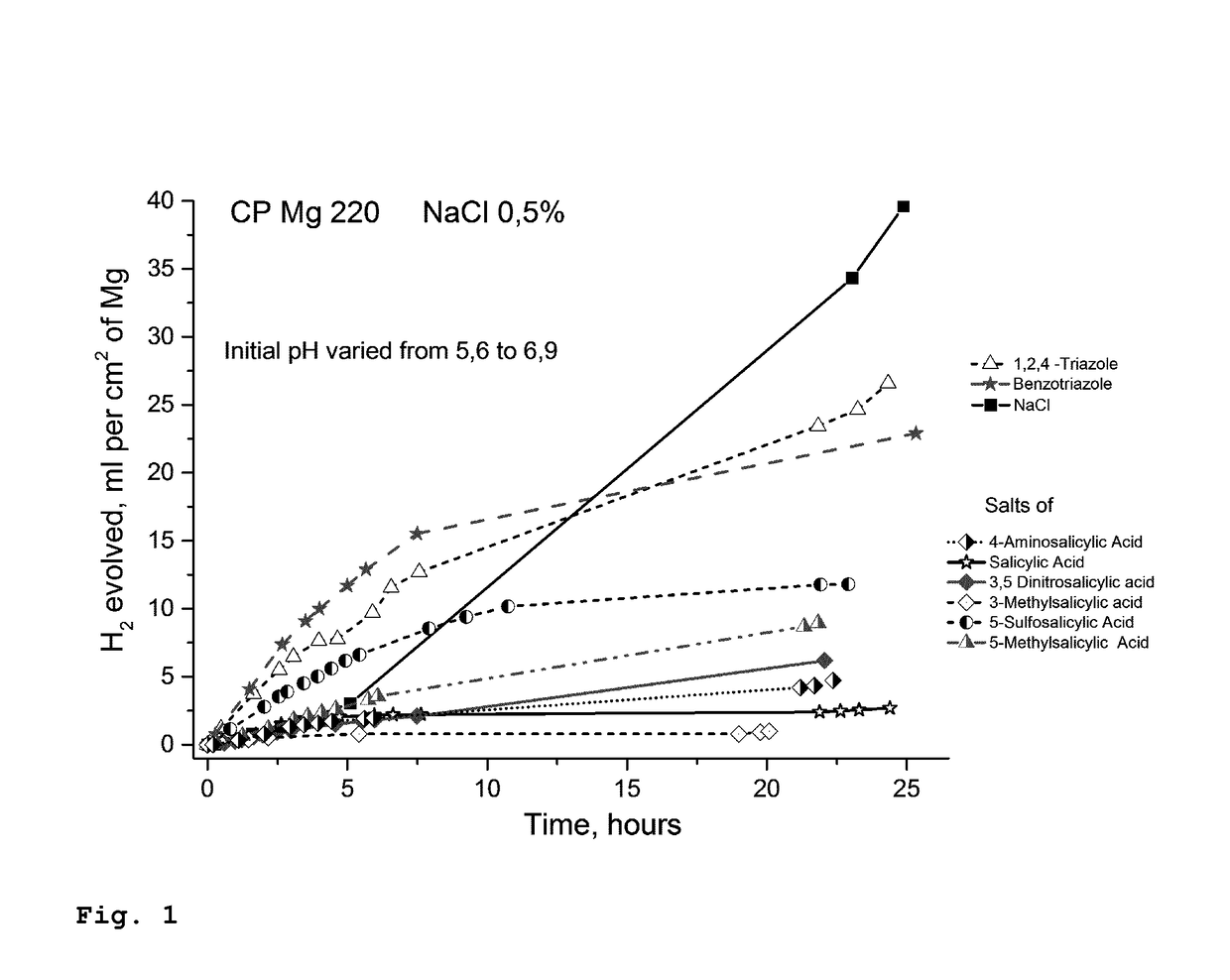

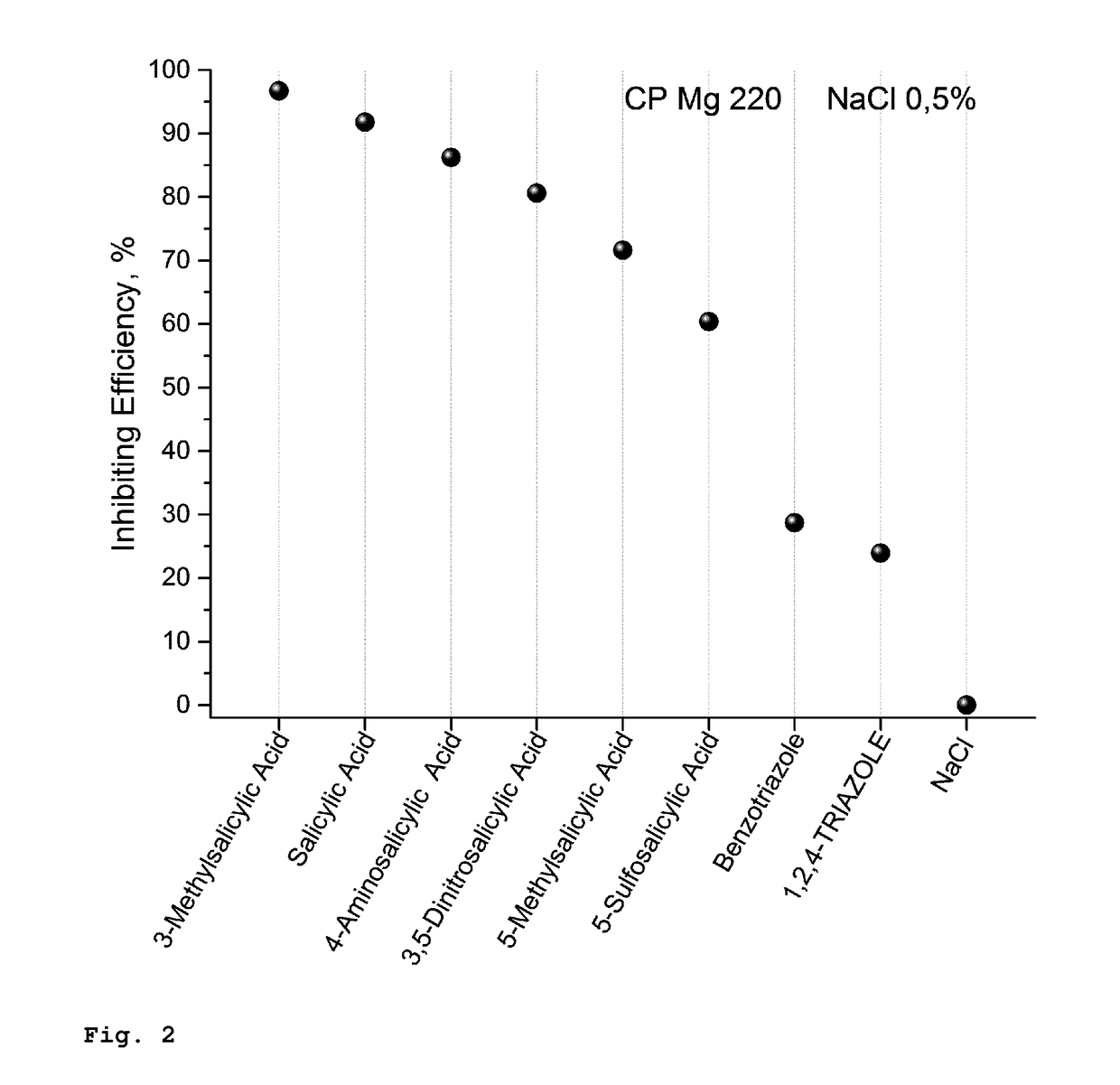

[0019]Preferred embodiments of the present invention are further illustrated by the following, non-limiting examples by referring to the figures below. Magnesium materials used for hydrogen evolution measurements presented in FIGS. 1 to 8 were as specified in Table 1. The ingots of HP Mg 51, WE43, ZE41, E21, AZ31, AZ91 and AM50 were shaved to receive the stripes with the surface area of 240 to 480 cm2 / g. This was done to ensure the identical chemical composition of each portion of the alloy used for testing solutions of different inhibitors. The plates (5.0 cm2 / g) of commercial purity magnesium (CP Mg 220) were tested.

TABLE 1Noble impurities found* in the materials used for hydrogenevolution tests.Impurity, ppmMaterialFeCuNiHigh Purity Mg (HP Mg5151)Commercial Purity Mg2205(CP Mg 220)WE43384746ZE4115198Elektron 21 (E21)122052AZ3115143AZ912248AM508133*Analysed by spark emission spectroscopy

[0020]FIG. 1 shows the results (normalized values) of hydrogen evolution measurements during im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion inhibiting | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com