Aluminum copper lithium alloy with improved mechanical strength and toughness

a technology of aluminum copper lithium alloy and mechanical strength, applied in the direction of electrochemical generators, batteries, electrical equipment, etc., can solve the problems of affecting the properties of other alloys, contaminating other alloys, and inability to obtain properties as beneficial as those obtained with alloys containing silver such as the aa2050 alloy, and achieve the effect of improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0100]In this example, several 400 mm thick slabs with the composition given in table 1 were cast.

TABLE 1Composition as a % by weight of Al—Cu—Li alloys cast in the form of a slab.CuMnMgZnLiAgZrFeSiTi543.610.340.170.560.930.130.100.0230.0150.022553.600.520.170.540.940.130.100.0230.0150.021563.600.340.430.570.930.000.100.0210.0150.022573.620.550.340.560.950.000.100.0170.0150.023713.620.360.430.560.900.010.100.0400.0240.031723.550.000.510.560.900.000.100.0350.0230.029

[0101]The slabs were homogenized at about 500° C. for about 12 hours and then scalped. The slabs were then hot rolled to obtain 50 mm, 102 mm or 130 mm thick slabs. The plates were solution heat treated at 527° C. and quenched with cold water. The plates were then stretched to give a permanent elongation of 4% or 6%.

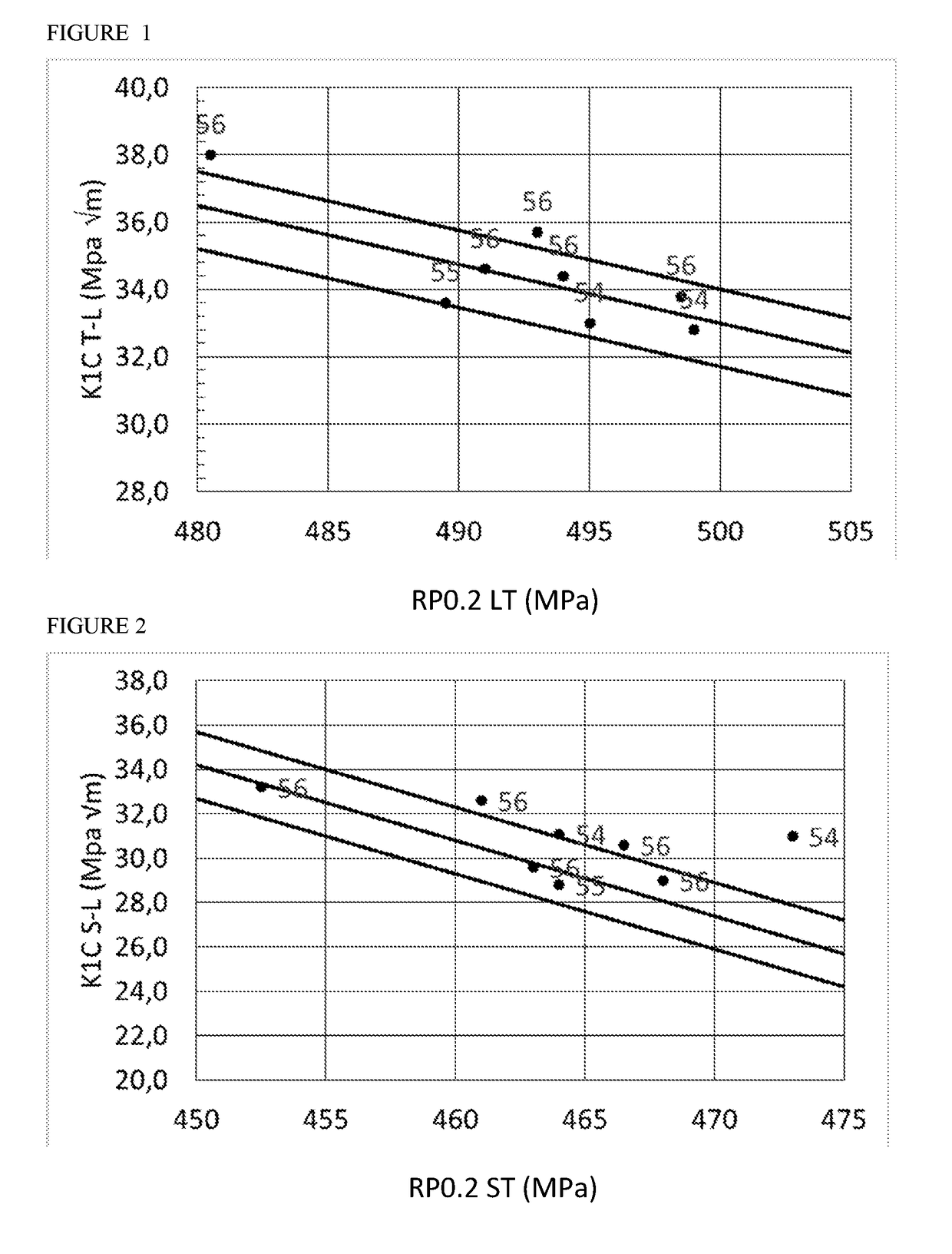

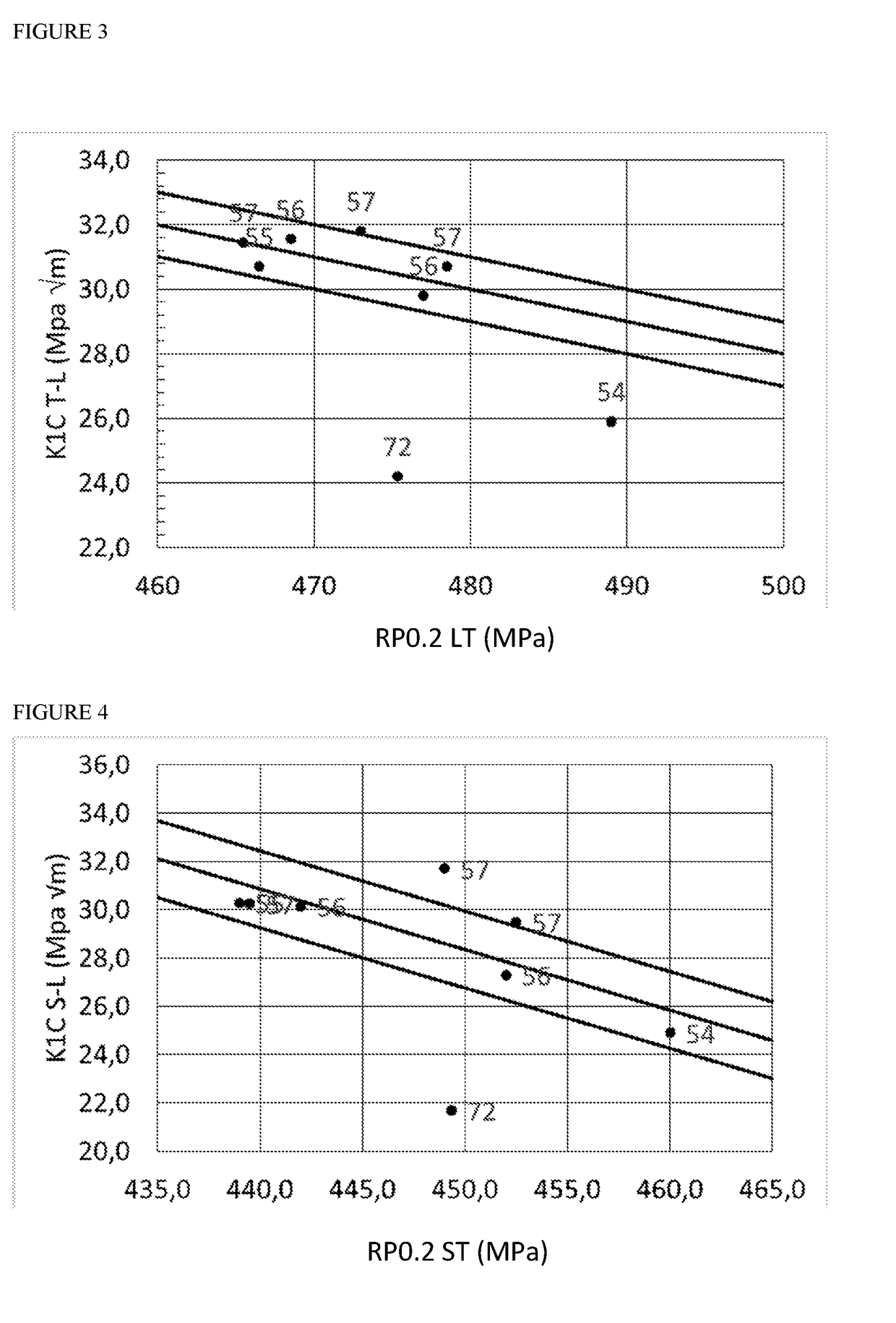

[0102]The plates were aged at 145° C. or at 150° C. Samples were taken at ¼-thickness to measure the static mechanical properties in tension and in toughness in the L, LT, L-T and T-L directions at ½-thickness...

example 2

[0106]In this example, several 120 mm thick slabs with the composition given in table 5 were cast.

TABLE 5Composition as a % by weight of Al—Cu—Li cast in the form of a slab.AlloyCuMnMgZnLiAgZrFeSiTi583.680.330.300.680.810.000.100.0210.0150.025593.640.350.320.000.850.120.100.0230.0150.025613.640.340.510.660.840.000.100.0200.0150.025623.670.350.330.700.860.140.100.0200.0150.025

[0107]The slabs were machined to a thickness of 100 mm. The slabs were homogenized at about 500° C. for about 12 hours and then scalped. After homogenization, the slabs were hot rolled to obtain 27 mm thick slabs. The plates were solution heat treated and quenched in cold water or in hot water at 90° C. so as to vary the quenching rate and stretched with a permanent set of 3.5%.

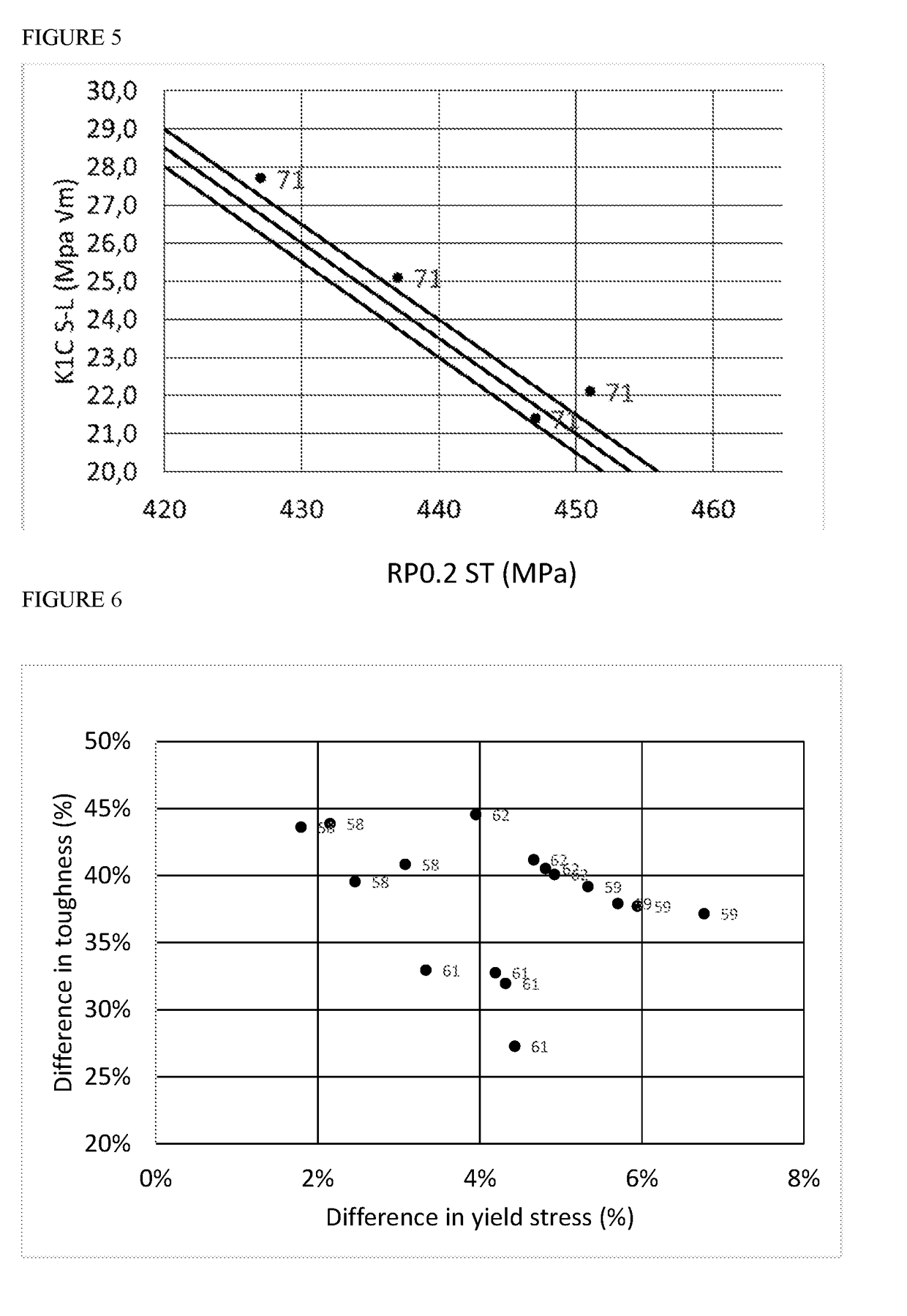

[0108]The plates were aged at between 15 h and 50 h at 155 ° C. Samples were taken at mid-thickness to measure static mechanical properties in tension and the toughness KQ. The width W of the test pieces used to measure the toughness in t...

example 3

[0110]In this example, we studied the effect of controlled stretching and ageing on toughness results Kapp and Keff measured by an R curve.

[0111]50 mm and 102 mm thick plates were obtained with alloys 56 and 71 in table 1. The plates were solution heat treated at 527° C. and were quenched in cold water. Plates made of alloy 56 were then stretched to a permanent elongation of 4% and plates made of alloy 71 were stretched to a permanent elongation of 6%.

[0112]Plates made of alloy 56 were then aged for 40 hours at 150° C. and plates made of alloy 71 were aged for 20 hours at 150° C.

[0113]Samples were taken at ½ thickness for 50 mm thick plates and at ¼-thickness for 102 mm and 130 mm thick plates, to measure mechanical static tension and toughness characteristics in plain stress Kapp and Keff in the L, LT, L-T and T-L directions. For toughness, the R curve was measured on CCT test pieces with width W=406 mm and thickness B=6.35 mm.

[0114]The results are summarized in Table 8 below:

TABLE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com