Wear part and method of making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Many industrial operations involve tools and other parts that engage abrasive materials. For example, tools in mining and drilling operations are quickly worn away by cyclic material contact. Downtime for replacement of worn tools and components during industrial operations can significantly increase operating costs. Increasing the service life of wear members by increasing surface hardness limits downtime and increases operation efficiency.

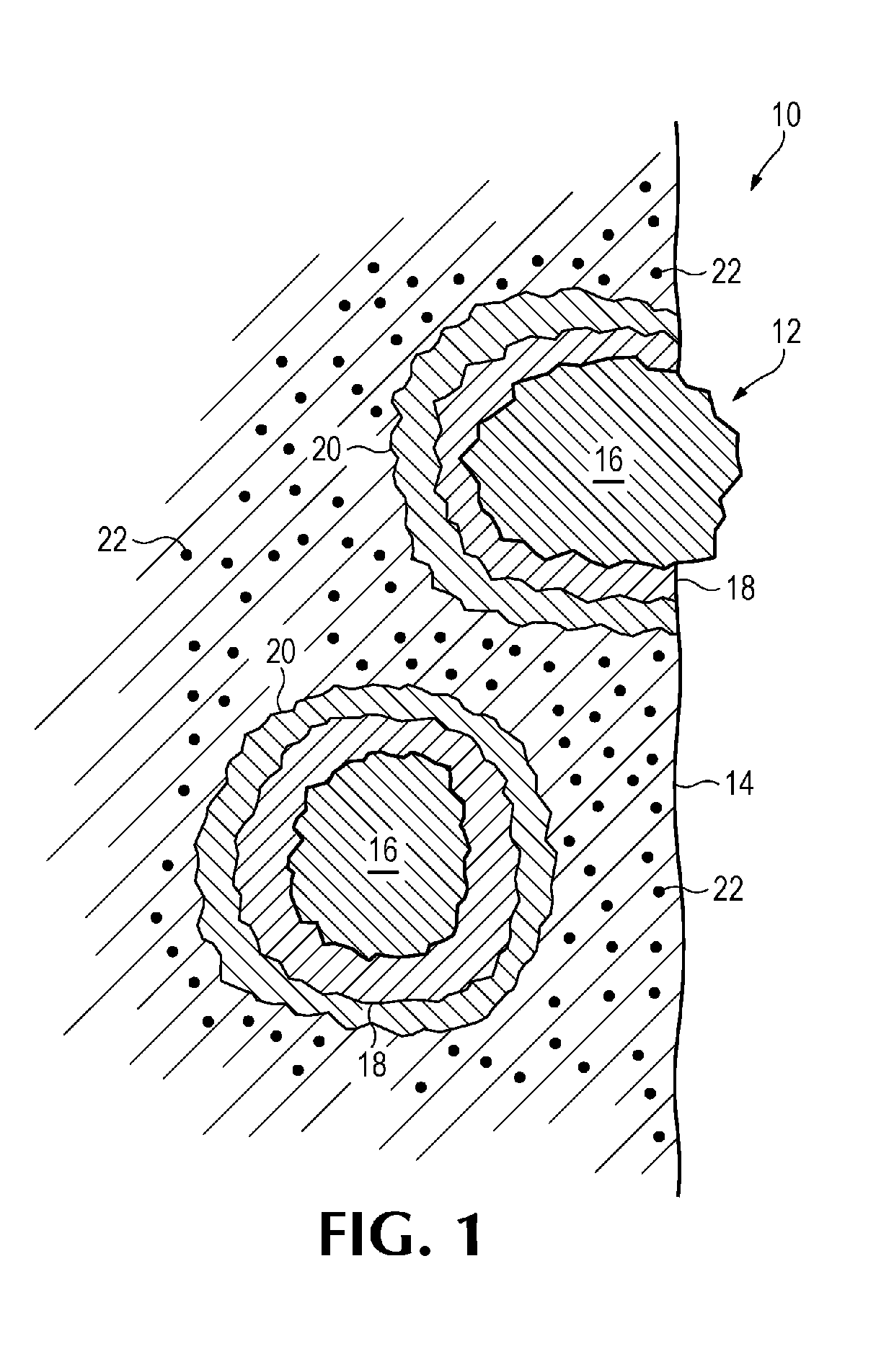

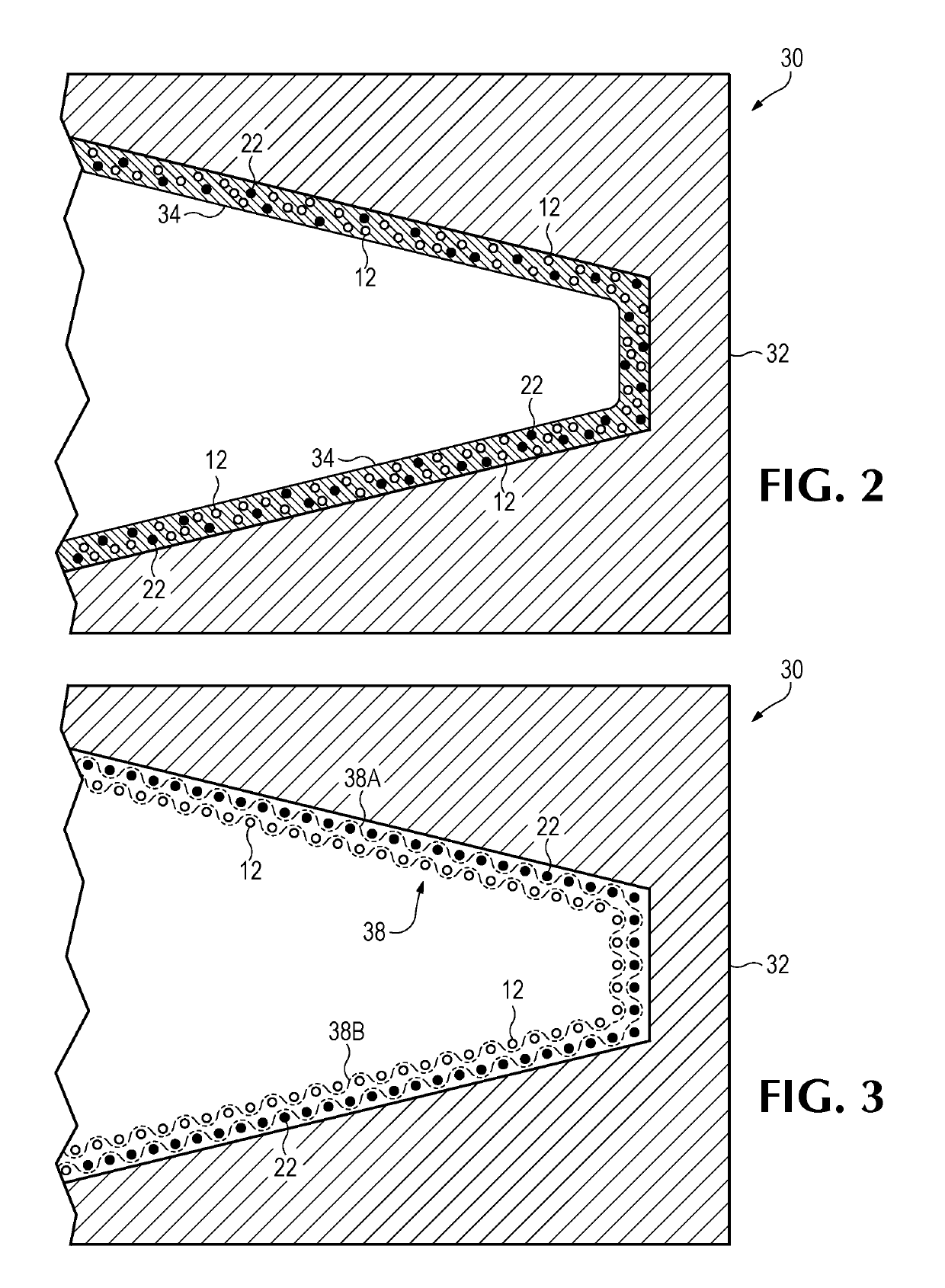

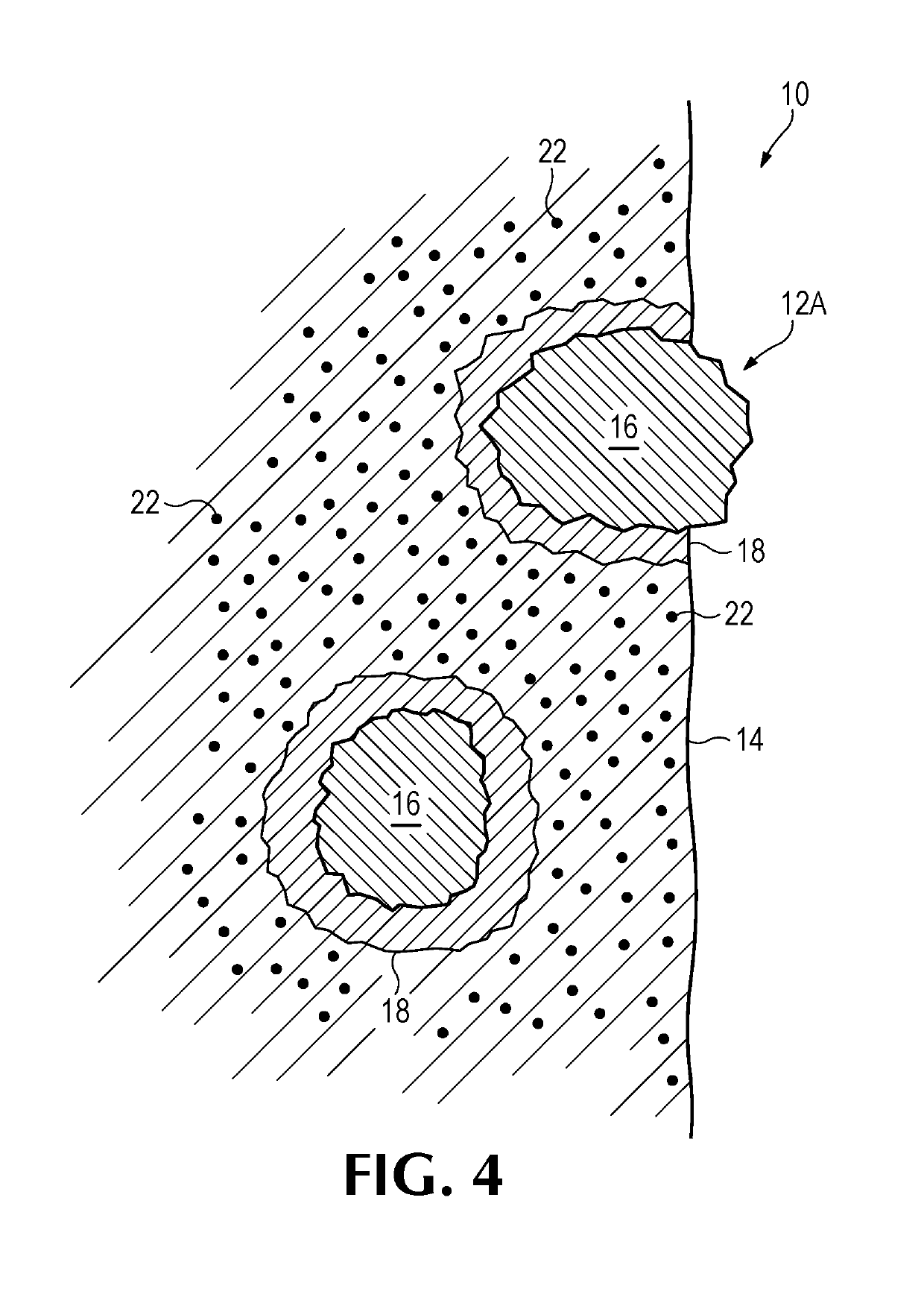

[0019]Incorporating hard particles in a matrix forming the surface of a member can significantly increase wear resistance. The term “particle” is used herein as a broad term to encompass hard material in many different forms including, e.g., spheroids, powder, whiskers, etc. The hard material can also be included in other forms such as preforms or other larger blocks. Tools and parts can be formed by infiltration where a molten matrix material fills spaces between hard particles such as tungsten carbide packed in a mold. In a part manufactu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com