Transformable gamma cameras

a technology of gamma cameras and transformable gamma, which is applied in the field of gamma cameras, can solve the problems of less efficient detection, higher cost than the almost 60-year old prior art, and detection with 5 mm thick cz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]While the invention may be subject to embodiment in different forms, there is shown in the drawings, and herein will be described in detail, specific embodiments with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention, and is not intended to limit the invention to that as illustrated and described herein.

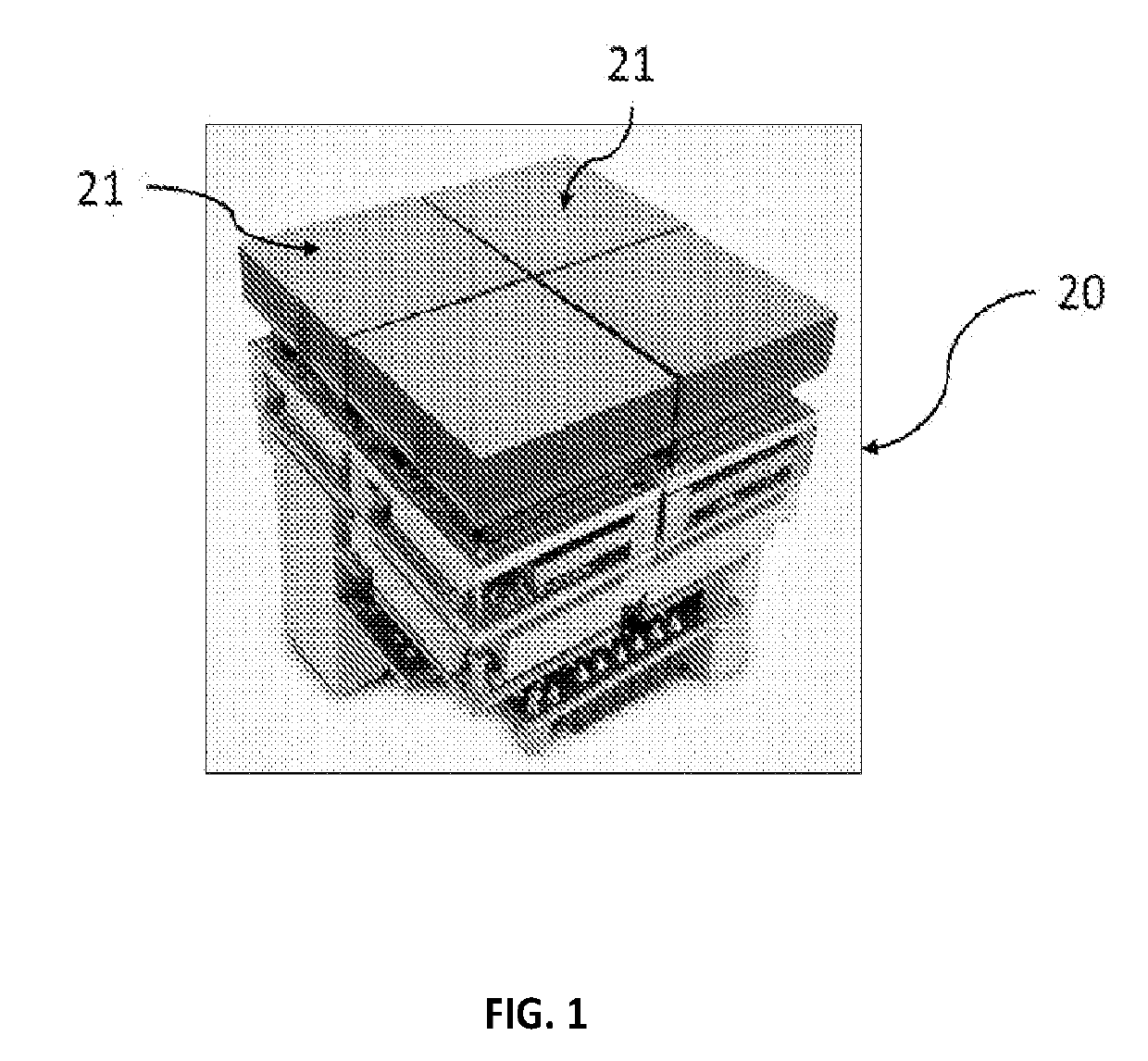

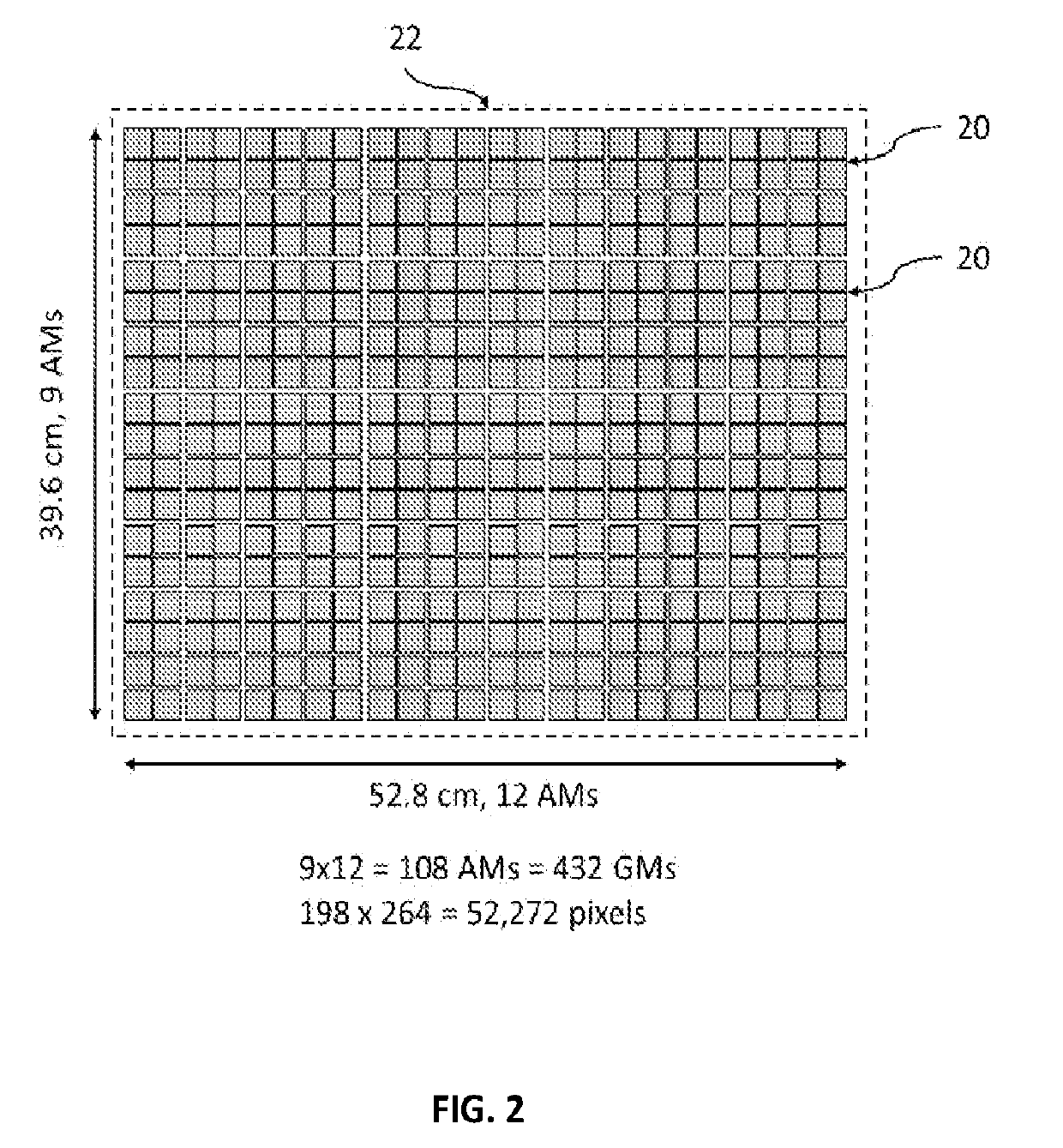

[0035]FIG. 1 shows a modular semiconductor direct conversion CZT gamma detector called D-Matrix™. This aggregator module (AM) 20 is composed of four CZT crystal detectors 21, each designated a gamma module (GM), each measuring about 2.2 cm×2.2 cm×0.5 cm thick. Each GM 21 may comprise a monolithic crystal or may comprise multiple tiles of CZT mounted in an abutting composite with small gaps between the tiles. The top GM 21 surface in FIG. 1 is the metallic cathode, which is typically monolithic but which can also be pixelated. Gamma photons generally enter the GM from the cathode side of the CZT crystal. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com