Method, Particle Sensor and Particle Sensor System for Measuring Particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

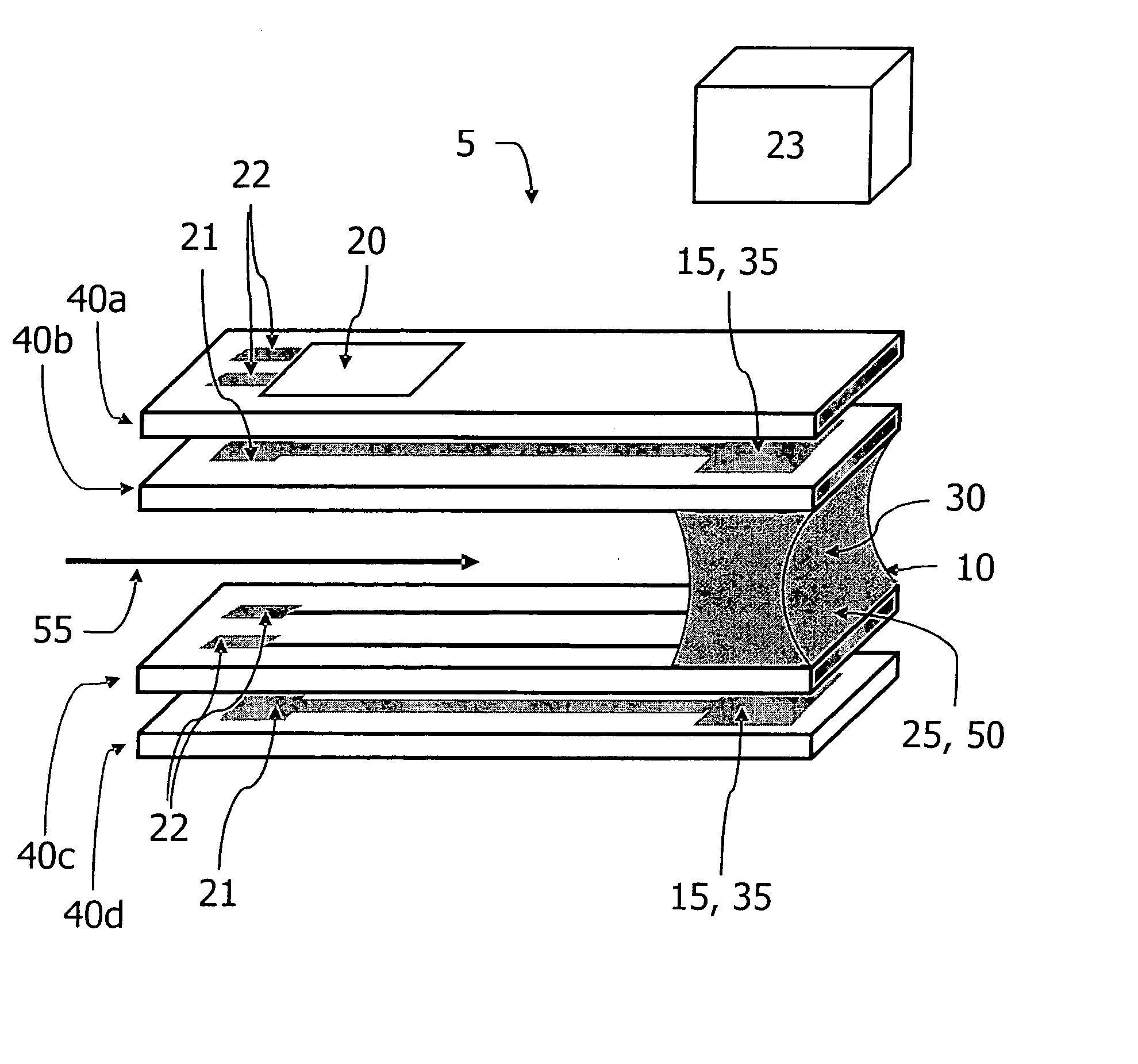

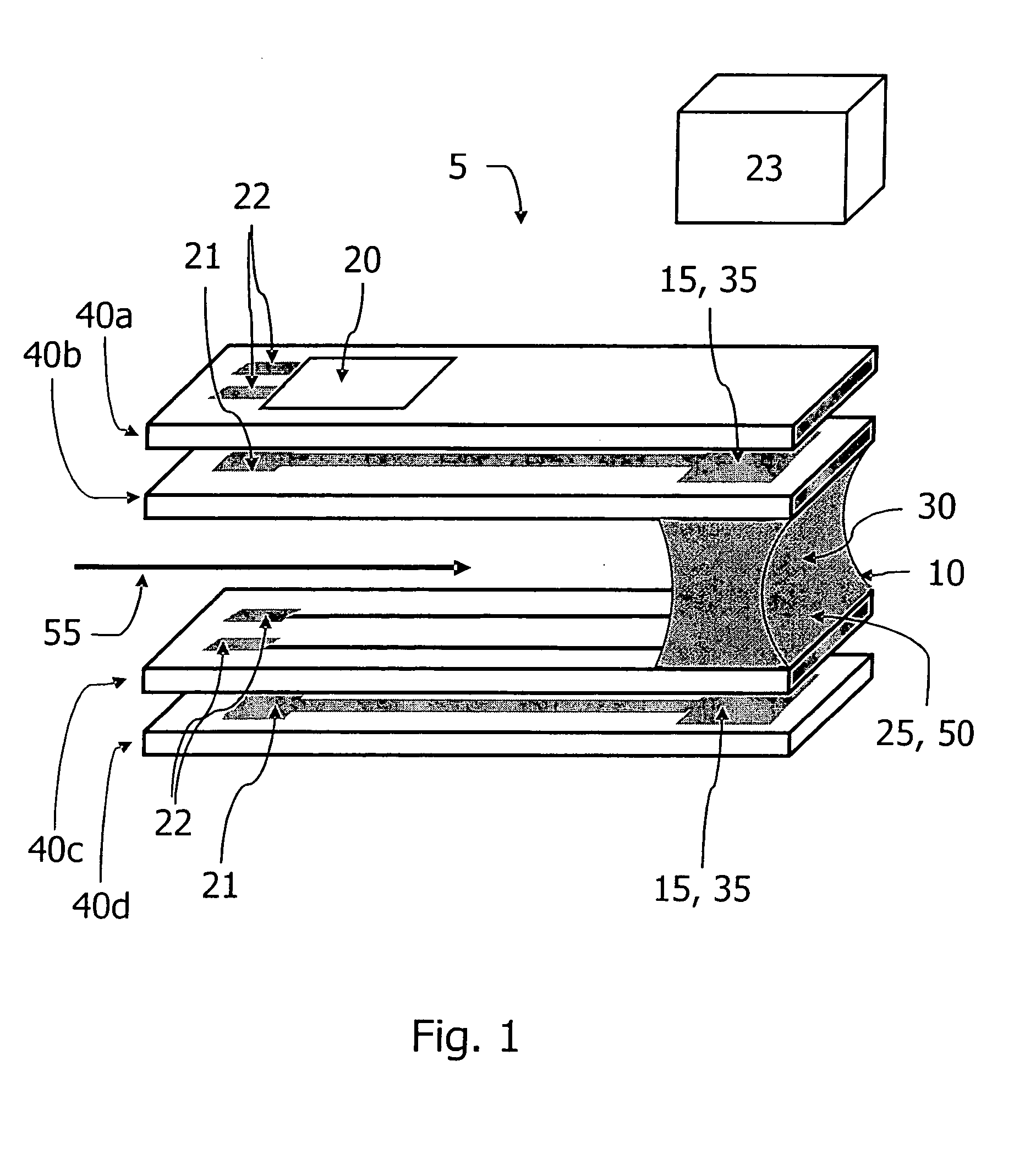

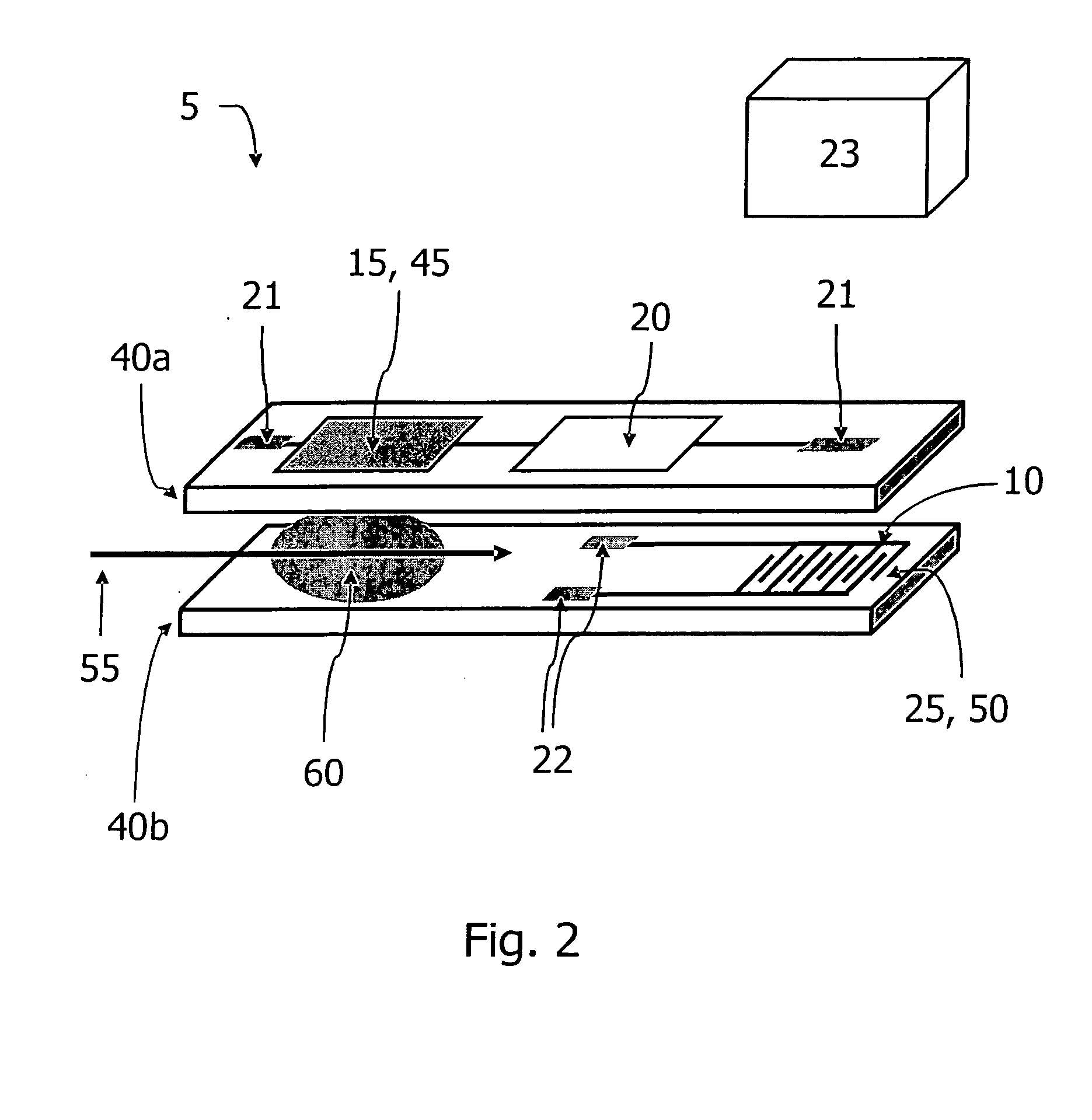

[0011]FIGS. 1 and 2 show a sensor for the detection of particles in a gas stream, which is used for installation in an exhaust branch of a motor vehicle, and may be situated downstream of a soot filter of a motor vehicle having a Diesel internal combustion engine. Alternatively, the sensor may also be situated upstream from the soot filter, in order to determine the soot input into the filter.

[0012] In a first exemplary embodiment as in FIG. 1, particulate sensor 5 has four base elements 40a, 40b, 40c, 40d. Base elements 40a, 40b, 40c, 40d are situated parallel to one another and congruent one above the other, between the two middle ones, 40b, 40c of the four base elements 40a, 40b, 40c, 40d, a greater clearance is provided as compared to the clearance between the two outer ones 40a, 40b and 40c, 40d of the four base elements 40a, 40b, 40c, 40d. Thus, base elements 40a and 40b, as well as 40c and 40d are laminated to each other, whereas between base elements 40b and 40c a gap is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com