Pharmaceutical-grade ferric organic compounds, uses thereof and methods of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

ethod for Synthesis of a Pharmaceutical-Grade Ferric Citrate

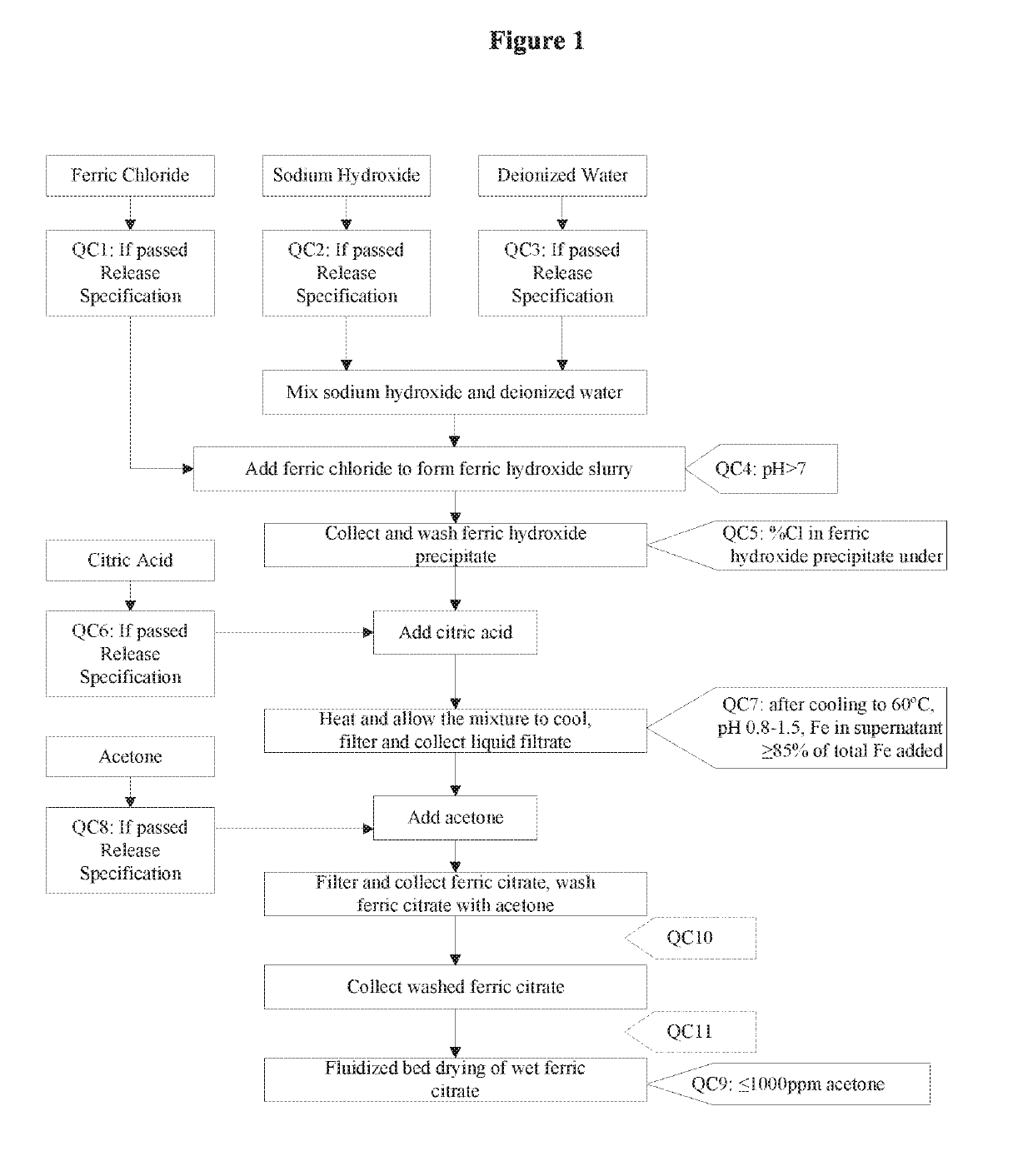

[0132]Referring to FIG. 1, which shows a general method of synthesis of the pharmaceutical-grade ferric citrate according to the invention, the flow chart shows implementation of quality control measures at selected stages of the synthesis process to ensure the final ferric citrate product complies with the Manufacture Release Specification as shown in Table A or any established Manufacture Release Specification for pharmaceutical-grade ferric citrate which have been approved or are suitable for human use. Other quality control measures or procedures, which are readily apparent to one of ordinary skill in the art, can be used or incorporated into the pharmaceutical-grade synthesis process to maintain the quality and purity of the final product and to increase the efficiency and yield of the synthesis process. See, for example, QC10 and QC11 in FIG. 1.

[0133]Examples of quality control measures employed in the synthesis proce...

example 1a

thod for Synthesis of a Pharmaceutical-Grade Ferric Organic Compounds

[0135]Referring to FIG. 10, which shows a general method of synthesis of the pharmaceutical-grade ferric organic compounds according to the invention, the flow chart shows implementation of quality control measures at selected stages of the synthesis process to ensure the final ferric citrate product complies with established Manufacture Release Specification for pharmaceutical-grade ferric organic compounds which have been approved or are suitable for human use. Other quality control measures or procedures, which are readily apparent to one of ordinary skill in the art, can be used or incorporated into the pharmaceutical-grade synthesis process to maintain the quality and purity of the final product and to increase the efficiency and yield of the synthesis process. See, for example, QC10A and QC11A in FIG. 10.

[0136]Examples of quality control measures employed in the synthesis process include: (QC4A) maintaining p...

example 2

y Profile of Ferric Organic Compounds According to the Invention

[0138]The ferric organic compounds produced according to the methods described above are more soluble than commercially available ferric organic compounds, over a wider range of pH levels. This increase in solubility of the ferric organic compounds of the present invention is believed to be a result of the unique significantly large active surface area of the ferric organic compounds of the present invention. For example, at pH 8.0, the intrinsic dissolution rate of ferric citrate of the present invention is 3.08 times greater than the commercially available ferric citrate. See Table 1.

[0139]The intrinsic dissolution rates of commercially available ferric citrate were compared with the ferric citrate of the present invention. The intrinsic dissolution rate is defined as the dissolution rate of pure substances under the condition of constant surface area. The dissolution rate and bioavailability of a drug substance is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com