Organic el image display device

an image display device and organic technology, applied in the direction of optical elements, identification means, instruments, etc., can solve the problems of image blurring, and achieve the effects of reducing image blurring, high brightness, and reducing image blurring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

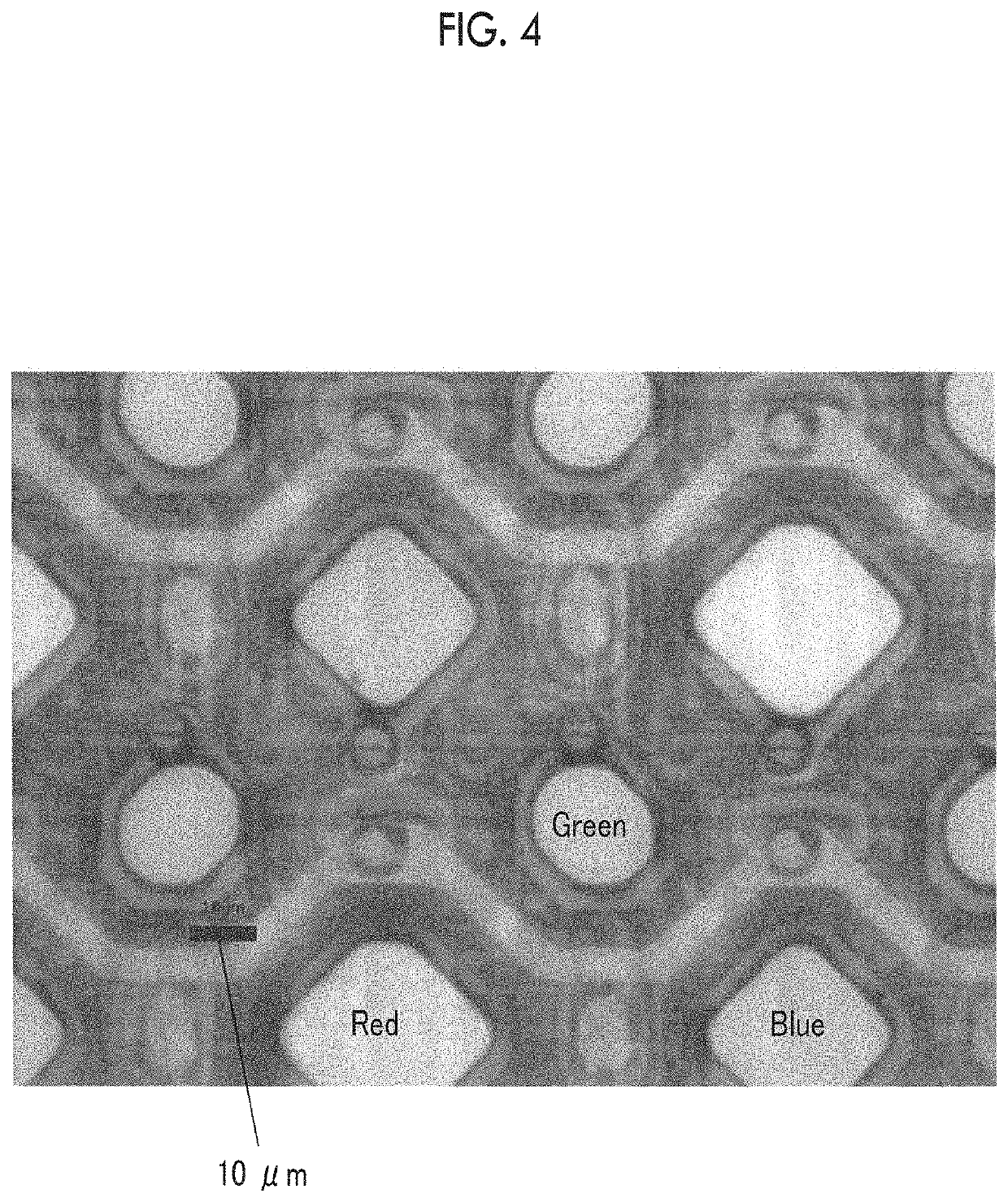

[0231]The alignment film composition A was uniformly applied to a glass substrate using a slit coater, and then dried for 2 minutes in an oven at 100° C. to obtain a glass substrate with an alignment film having a thickness of 0.5 μm. The alignment film was rubbed in a direction parallel to the coating direction. The liquid crystal composition LC-1 was applied to the rubbed surface. Next, the composition was heated and aged at a film surface temperature of 95° C. for 60 seconds, and immediately thereafter, the composition was exposed via a photo mask A shown in FIG. 3 (value of b: 57.7 μm: value of b corresponding to L of Expression (1)) at an exposure dose of 100 mJ / cm2 using a PLA-501F exposure machine (super high pressure mercury lamp) manufactured by Canon Inc. under air at 25° C. In FIG. 3, white refers to a transmission part and black refers to a shielding part. Then, by exposing the entire substrate to light under nitrogen by an air-cooled metal halide lamp (manufactured by E...

example 2

[0234]A layer having the cholesteric liquid crystal layer pattern was prepared in the same manner as in Example 1 except that a photo mask B, in which the value of b in FIG. 3 was set to 30.00 μm, was used during pattern formation. Furthermore, a layer having the cholesteric liquid crystal layer pattern and a circularly polarizing plate CP1 are laminated in the same manner as in Example 1 on the barrier layer surface of the light emitting element substrate prepared in the same manner as in Example 1 to prepare the image display device for evaluation.

example 3

[0235]A layer having the cholesteric liquid crystal layer pattern was prepared in the same manner as in Example 1 except that a photo mask C, in which the value of b in FIG. 3 was set to 20.00 μm, was used during pattern formation. Furthermore, a layer having the cholesteric liquid crystal layer pattern and a circularly polarizing plate CP1 were laminated in the same order as in Example 1 on the barrier layer surface of the light emitting element substrate prepared in the same manner as in Example 1 to prepare the image display device for evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com