Corrosion inhibitor

a corrosion inhibitor and corrosion inhibitor technology, applied in anti-corrosion paints, polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to meet environmental requirements, invariably less effective than chromate counterparts, and achieve improved corrosion resistance, prevent further corrosion, and prevent further corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

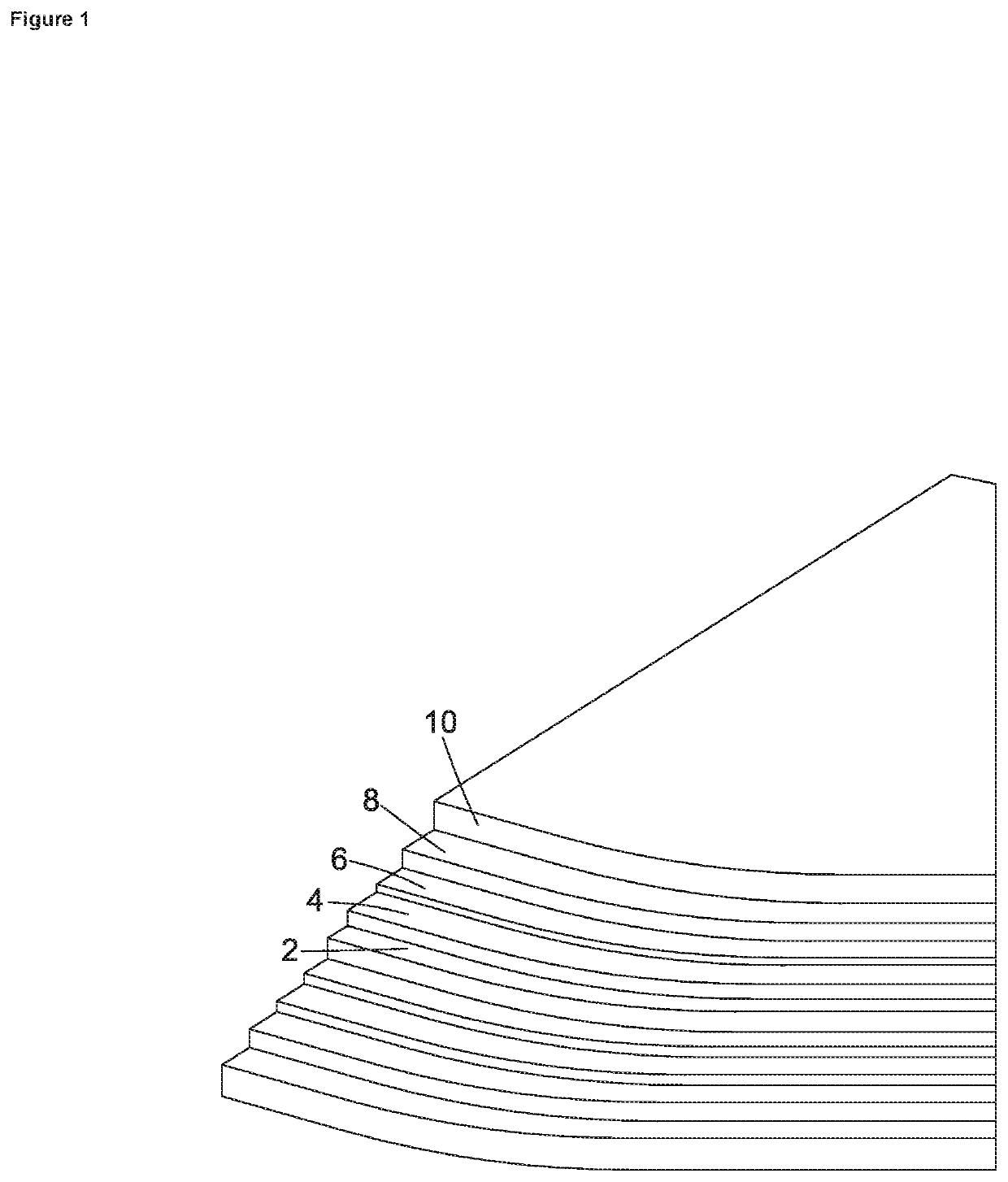

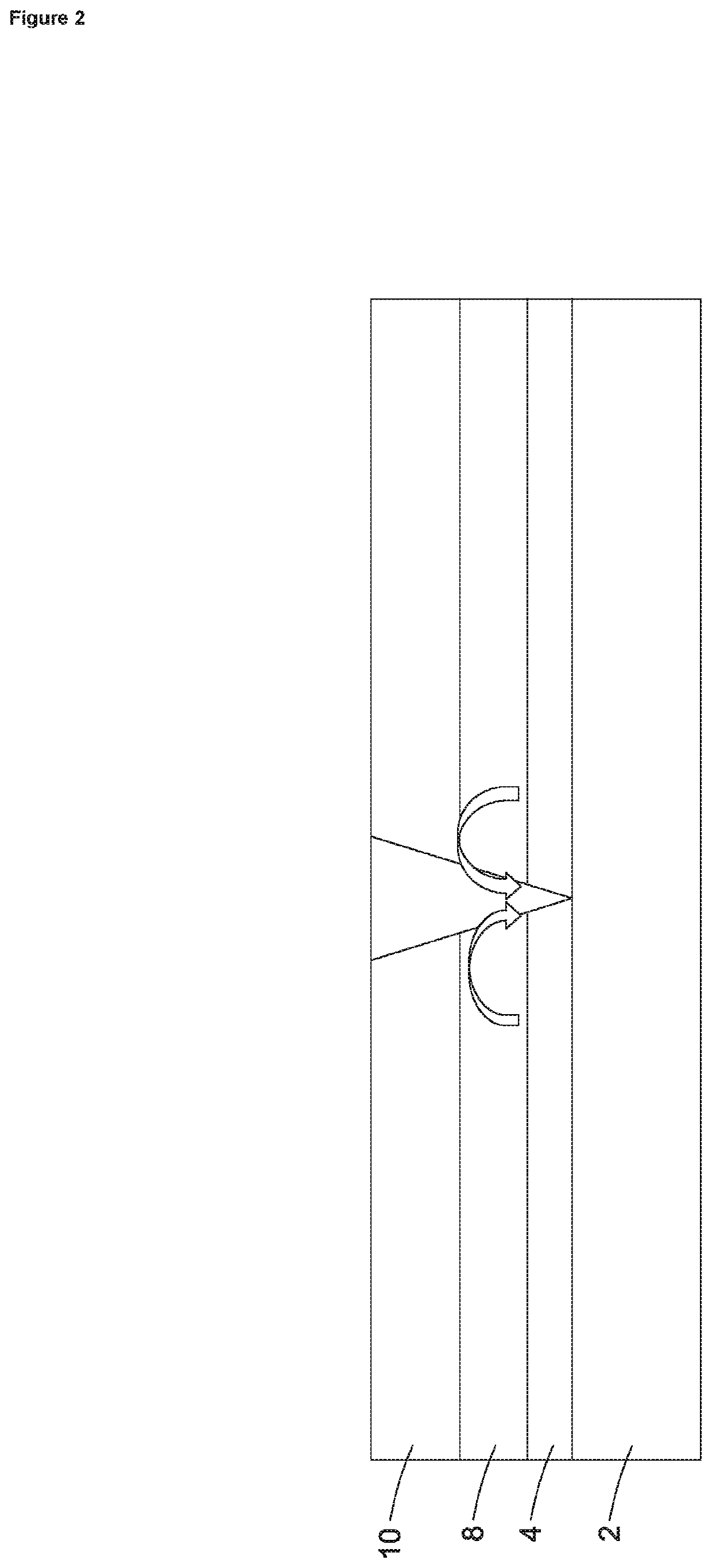

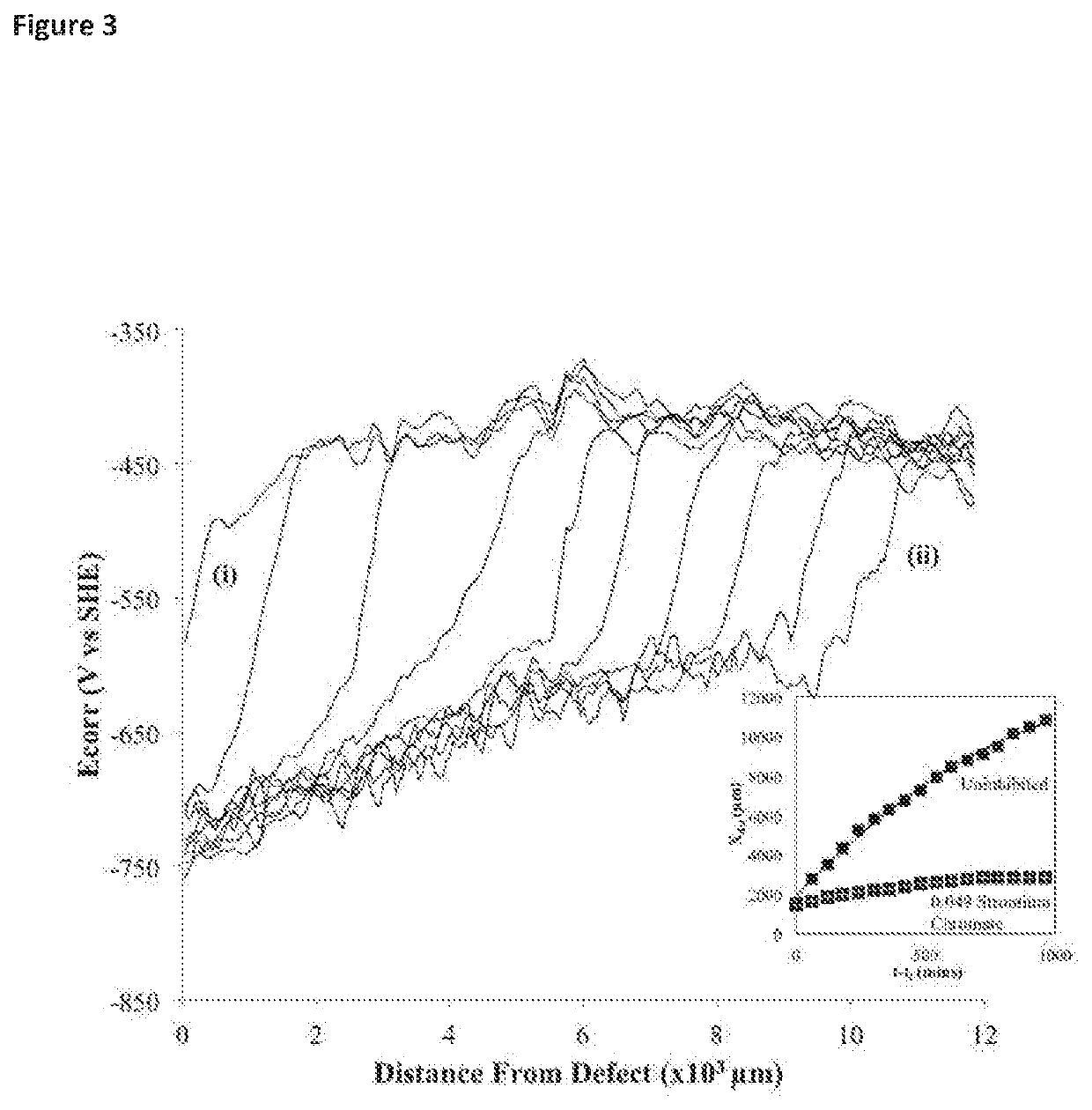

[0047]The present invention has been developed to provide a smart-release corrosion inhibitor which has particular but not exclusive application in the protection of galvanised steel from corrosion. The inhibitor, which is usually applied as a primer to a metal surface in liquid form at room temperature and pressure contains an organic ion, preferably an azole, and even more preferably benzotriazolate (BTA). This is added to an ion exchange matrix. The ion exchange resin matrix in one embodiment is a divinylbenzene copolymer with a sulphonate functional group as shown below. The benzene ring with the three nitrogen atoms is benzatriazolate and is positively charged due to extra hydrogen cation. The ion exchange resin matrix is the remainder and is shown as being negatively charged.

[0048]The corrosion inhibitor structure is formed of repeating units of the ion exchange resin with a sulphonated group having a negative charge to hold the corrosion inhibiting cation of protonated benzot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particulate size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particulate size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com