Impact tool

a tool and impact technology, applied in the field of impact tools, can solve the problems of short working life of magnetic torque sensors, significant errors in measuring signals, and short working life of measuring signals, and achieve the effects of low clock frequency, high working life and extremely cheap units of measuremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

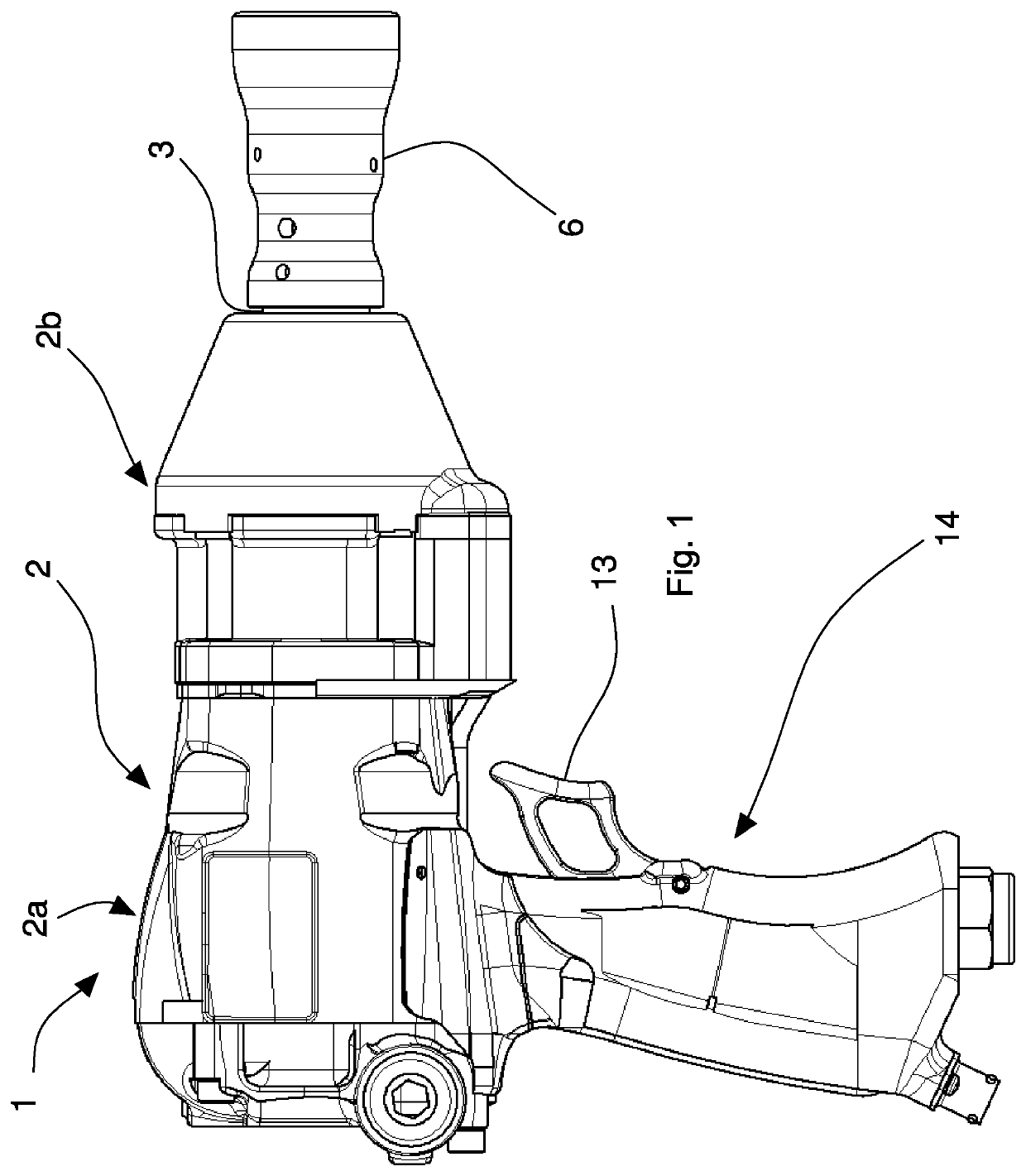

[0039]With reference to the aforesaid Figures, overall with 1 an impact tool has been indicated that, in the specific case, is an impact wrench usable, for example, for fitting and removing wheels of vehicles, in particular racing cars or motorcycles.

[0040]With reference in particular to FIG. 1, the impact tool 1 comprises a containing and protection casing 2 provided with a first part 2a arranged for housing internally a rotating hammer (not shown in the Figures) rotated by a motor (also not shown in the Figures). In the specific case, the motor is of pneumatic type. The rotating hammer acts as a flywheel for accumulating mechanical energy.

[0041]In the first part 2a a grip 14 is obtained for gripping of the impact tool 1 by an operator to facilitate the operations of fitting or removing one or more wheel of vehicles.

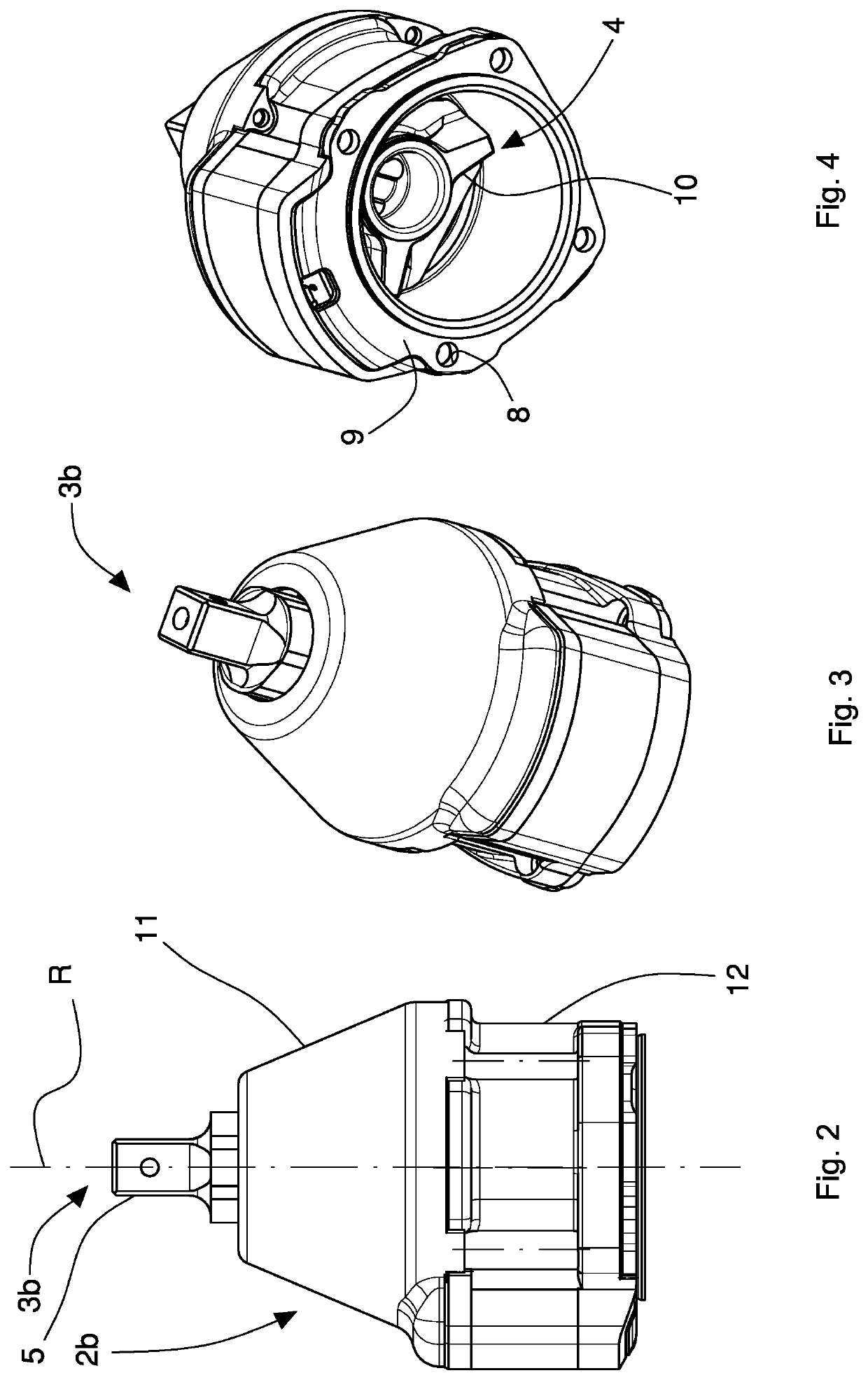

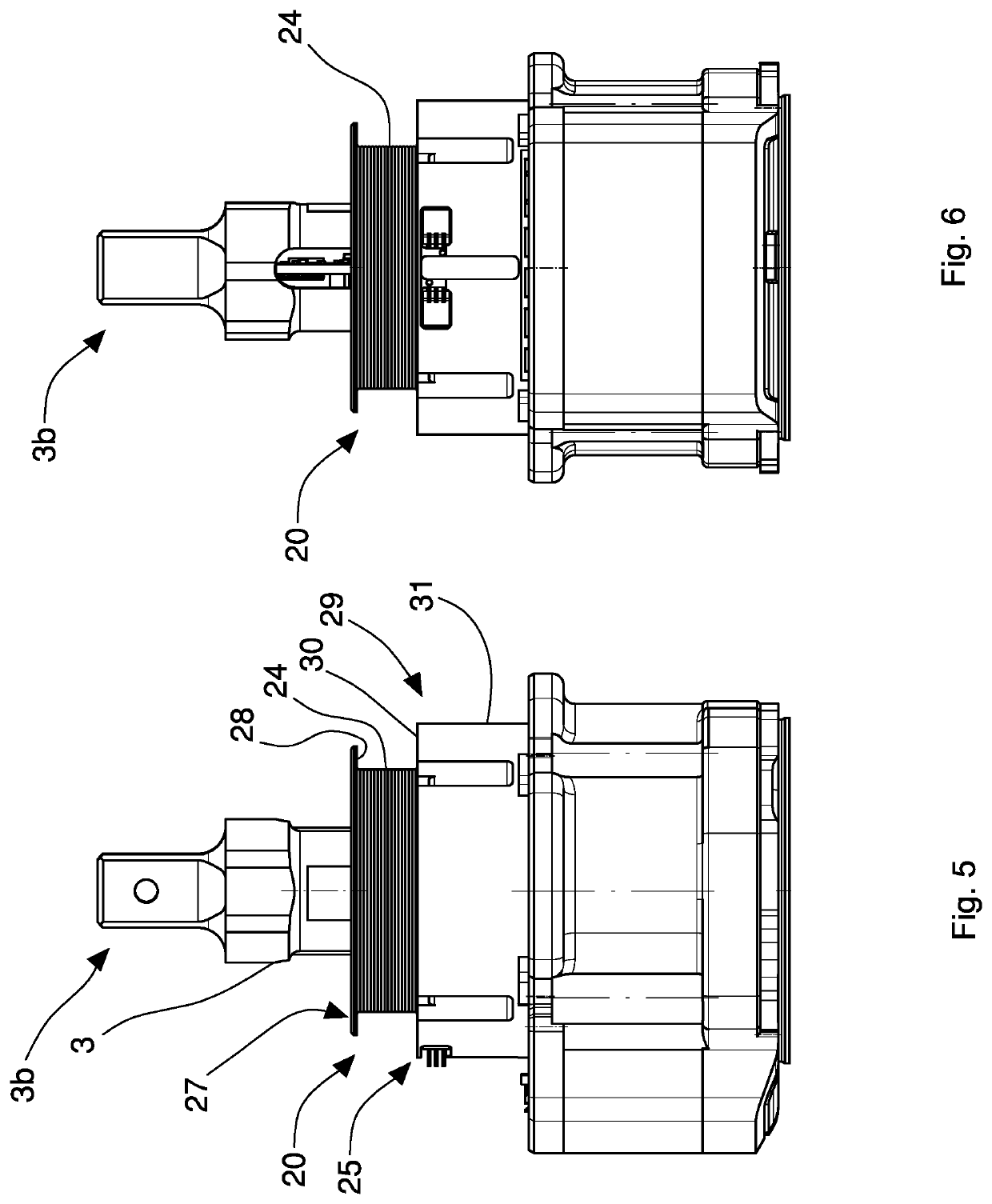

[0042]The impact tool 1 comprises, further, an output shaft 3 rotatable around a rotation axis R (FIG. 2). The output shaft 3 can have, as in the specific case, a proxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com