Coolant compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

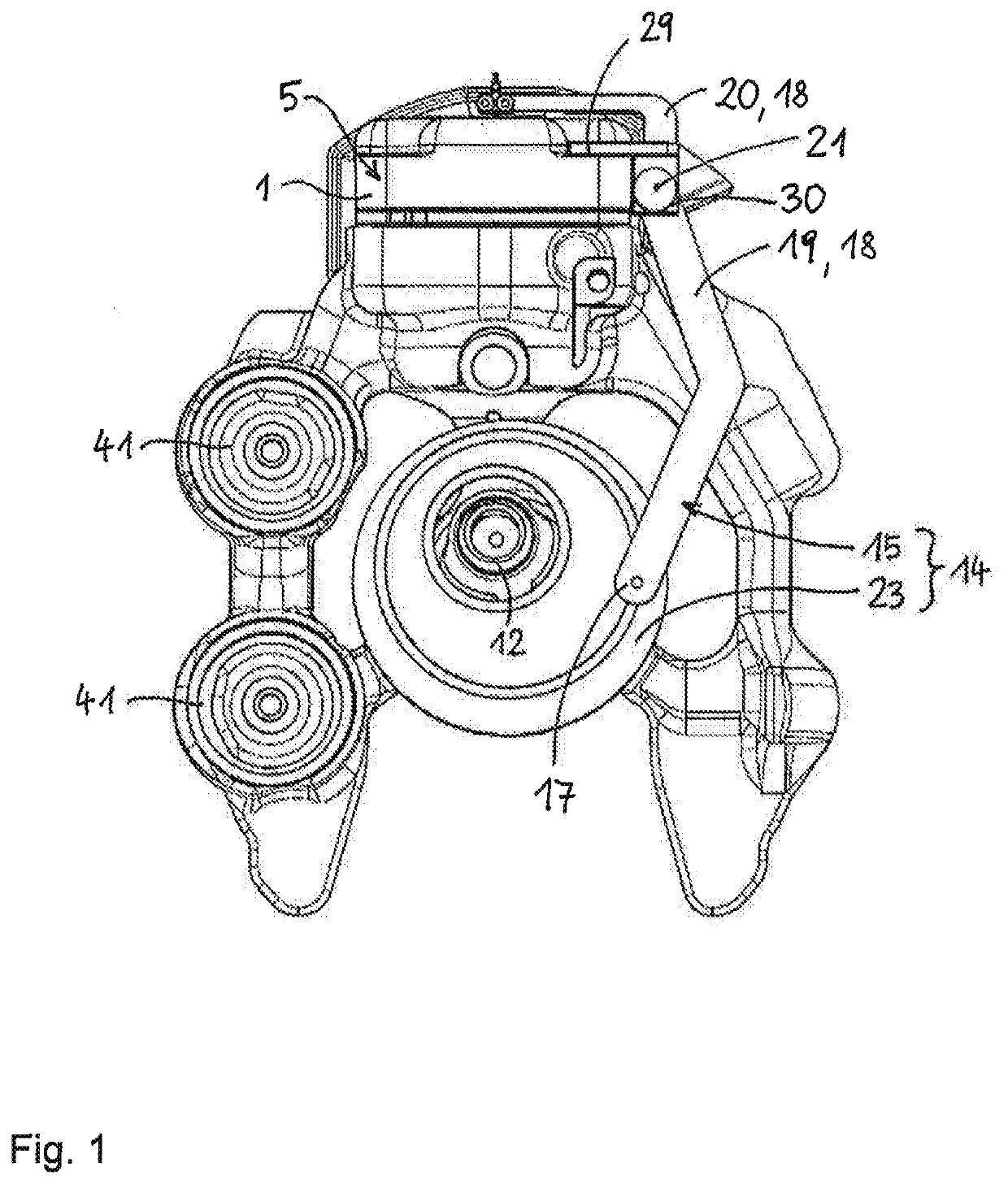

[0049]FIG. 1 shows a plan view of a coolant compressor according to the invention, wherein the components of the coolant compressor are enclosed in a hermetically sealable compressor housing, which is not represented here in order to be able to show the interior of the compressor housing.

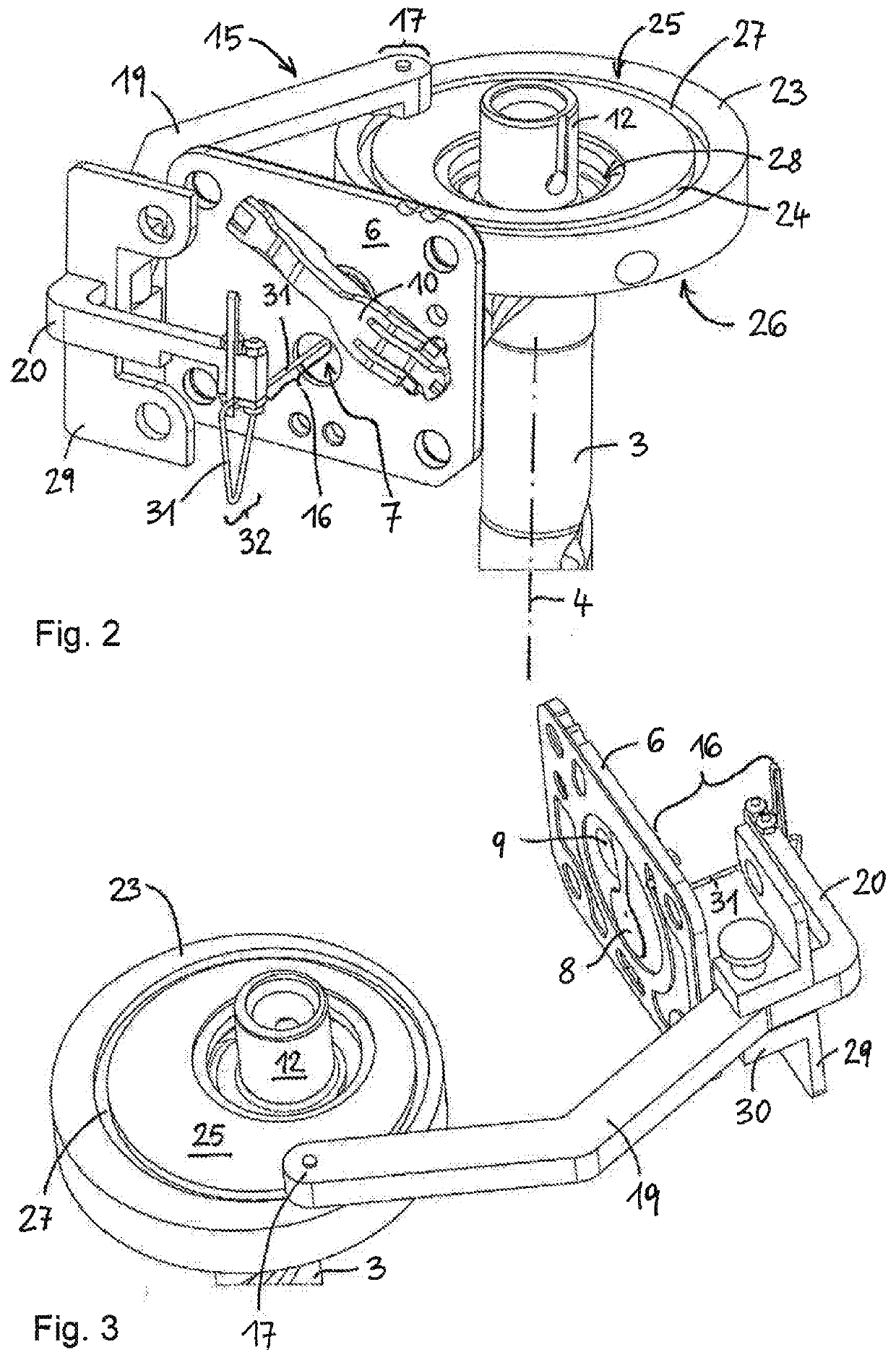

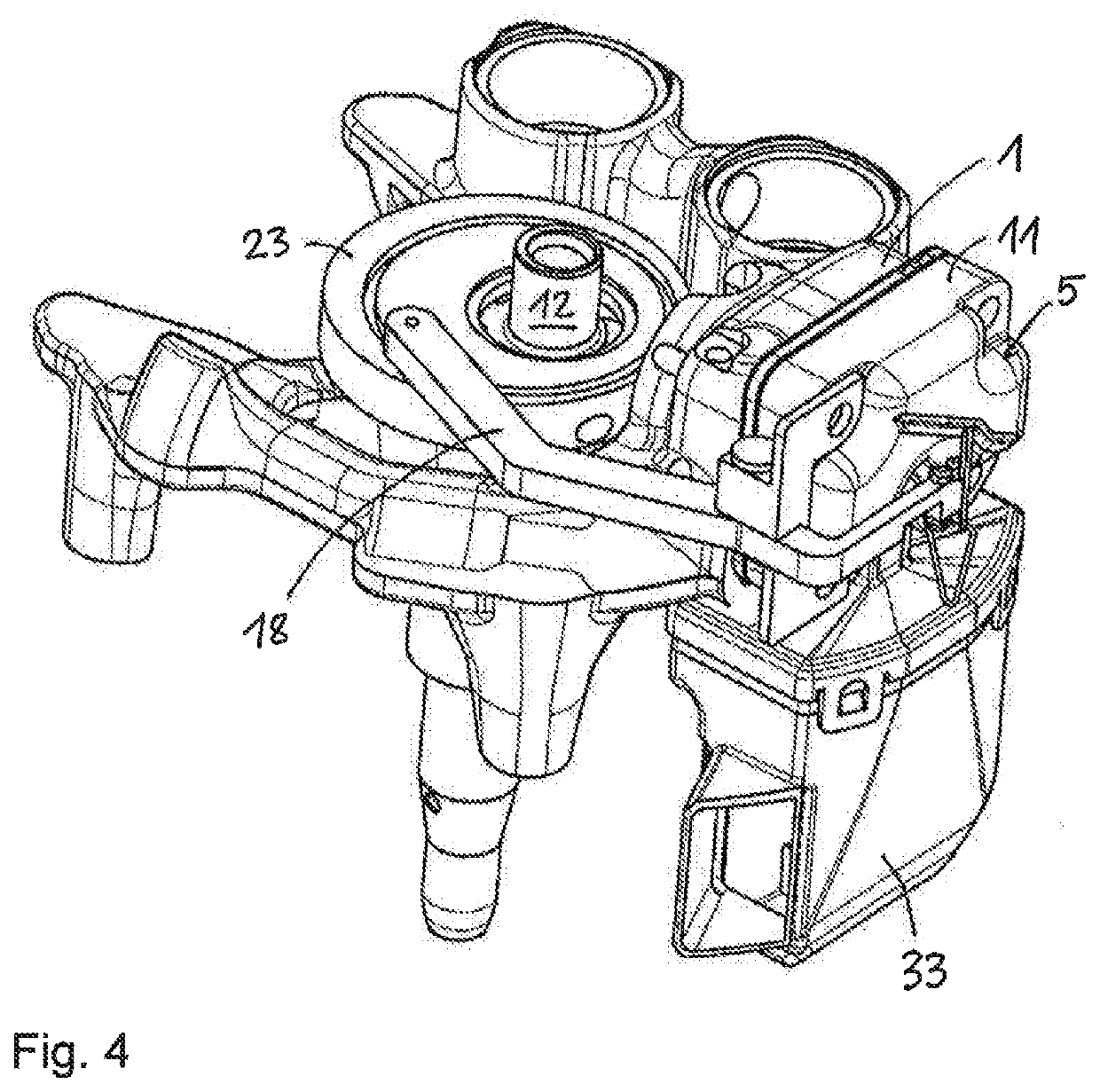

[0050]The coolant compressor comprises an electrical drive unit comprising a stator and a rotor, which is connected for conjoint rotation to a crankshaft 3 (see FIGS. 2 and 3). The crankshaft 3 is drivable by means of the electrical drive unit, and a piston-cylinder unit operatively connected to a crank pin 12 of the crankshaft 3 arranged eccentrically relative to the longitudinal axis 4 of the crankshaft 3 cyclically draws in and compresses coolant. The piston-cylinder unit comprises a cylinder housing 1 enclosing a cylinder, and a piston 2 translationally guided therein (see FIG. 7). The piston 2 is connected via a connecting rod 13 to the crank pin 12 of the crankshaft 3 so that the piston 2 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com