Aluminum alloy and manufacturing method thereof

a technology of aluminum alloy and manufacturing method, which is applied in the field of aluminum alloy, can solve the problems of low tensile strength of alloys, crack generation, and difficulty in simultaneously improving tensile strength and elongation, and achieves the effects of improving casting properties, high strength and elongation, and efficient production of aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

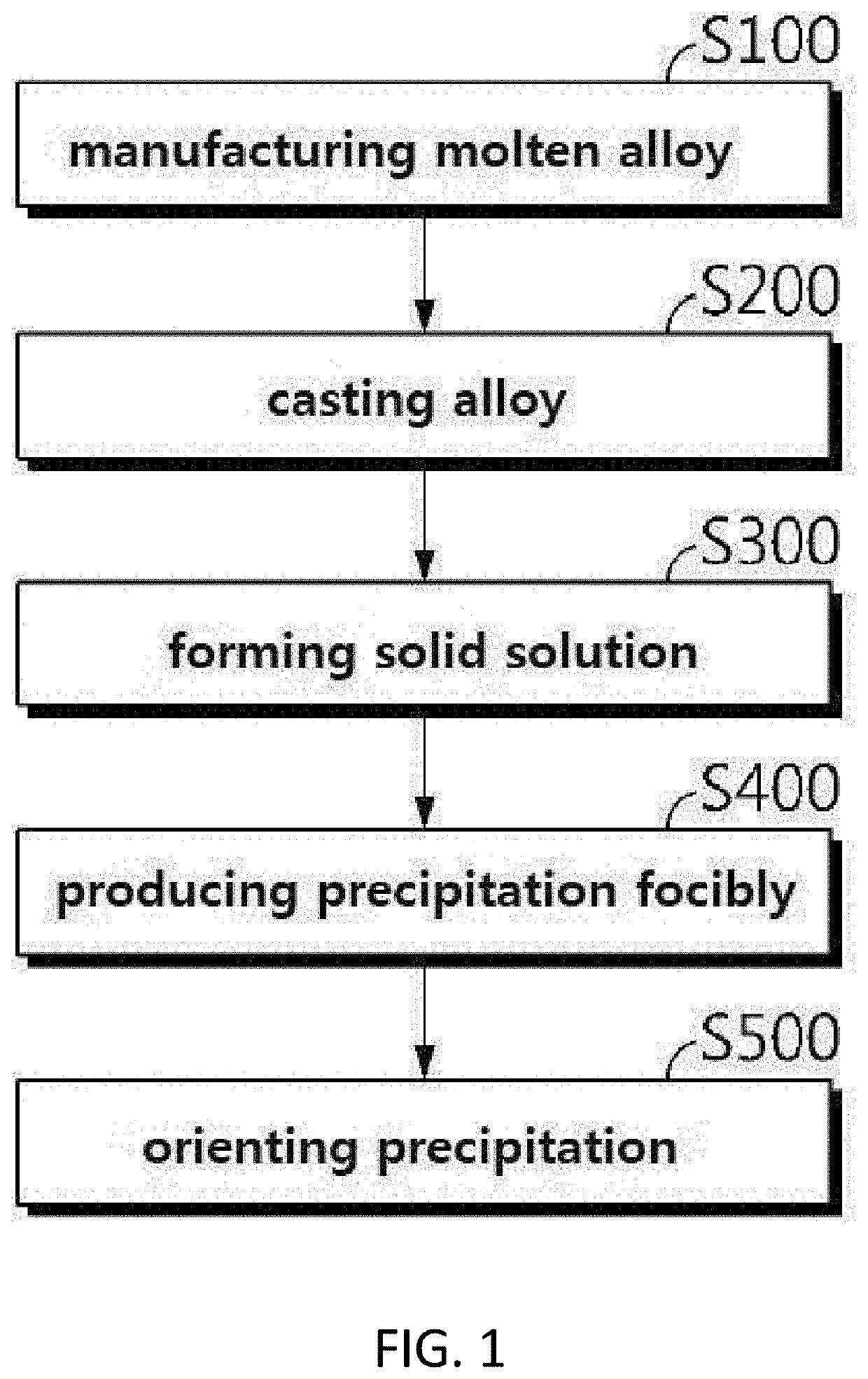

Method used

Image

Examples

experimental example

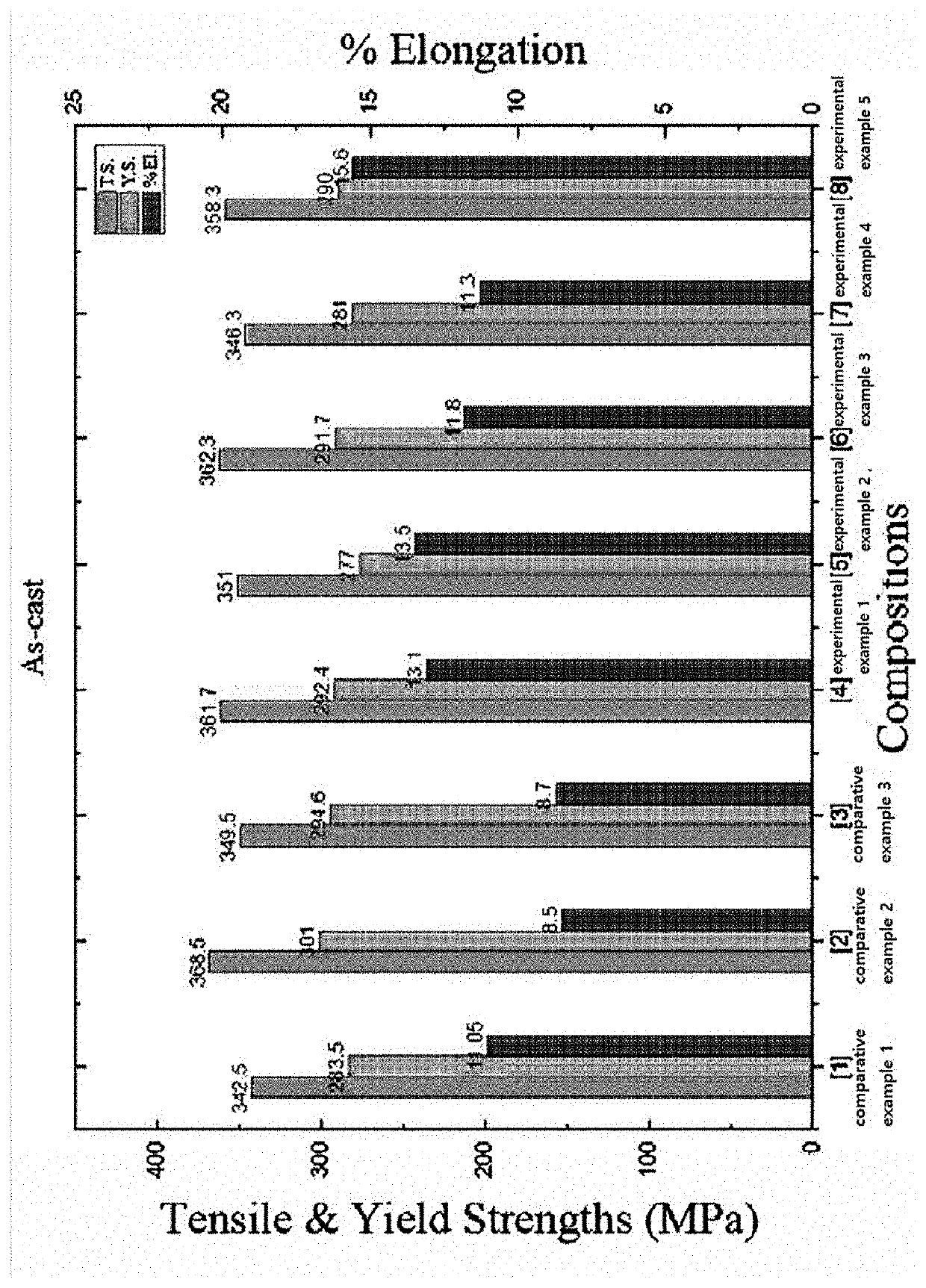

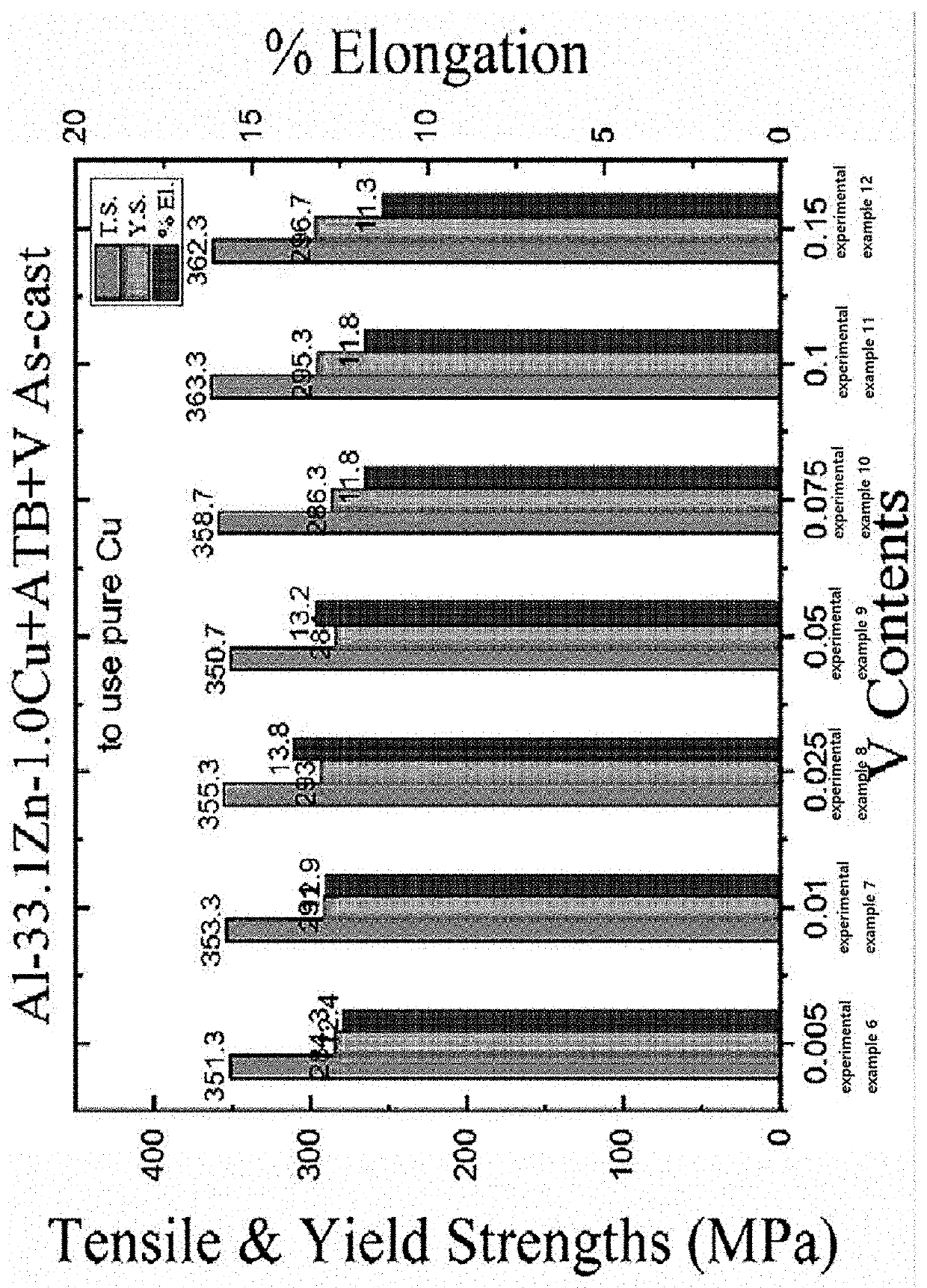

[0065]Hereinafter, the present invention will be described in more detail with reference to specific production examples, comparative examples and their property evaluation results of the present invention.

[0066]Table 1 shows contents of experimental examples and comparative examples of the aluminum alloy according to the present invention.

[0067]The aluminum alloy of the present invention, having the content of each element in Table 1 was cast by a compact 50 Kg electric furnace melting and high-frequency induction melting. All alloys were cast using a 99.9% pure raw material and master alloy. Using an electric furnace, 5 kg of each specimen was melted and temperature was maintained at 700° C. After complete melting, a degassing operation was performed with Ar gas for 10 minutes. After molten state was maintained for 10 minutes, it was filled into a sand mold.

[0068]In five minutes after filling, the ingot was taken out of the mold. Homogenization treatment was carried out at 450° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com