Busbar assembly with alignment and touch-proof features for network elements

a technology of network elements and assembly parts, applied in the direction of support structure mounting, electrical equipment, servers, etc., can solve the problems of increasing power densities within new network communication systems, power demand too high for power planes, and power distribution in shelf-mounted equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0061]FIGS. 8-11 shows various views of an alignment block 60, which may be representative of one of the alignment blocks 28, 28a shown in FIGS. 4-7. FIG. 8 is a front perspective view of the alignment block 60 and FIG. 9 is a back perspective view of the alignment block 60. FIG. 10 is a front view and FIG. 11 is back view of the alignment block 60.

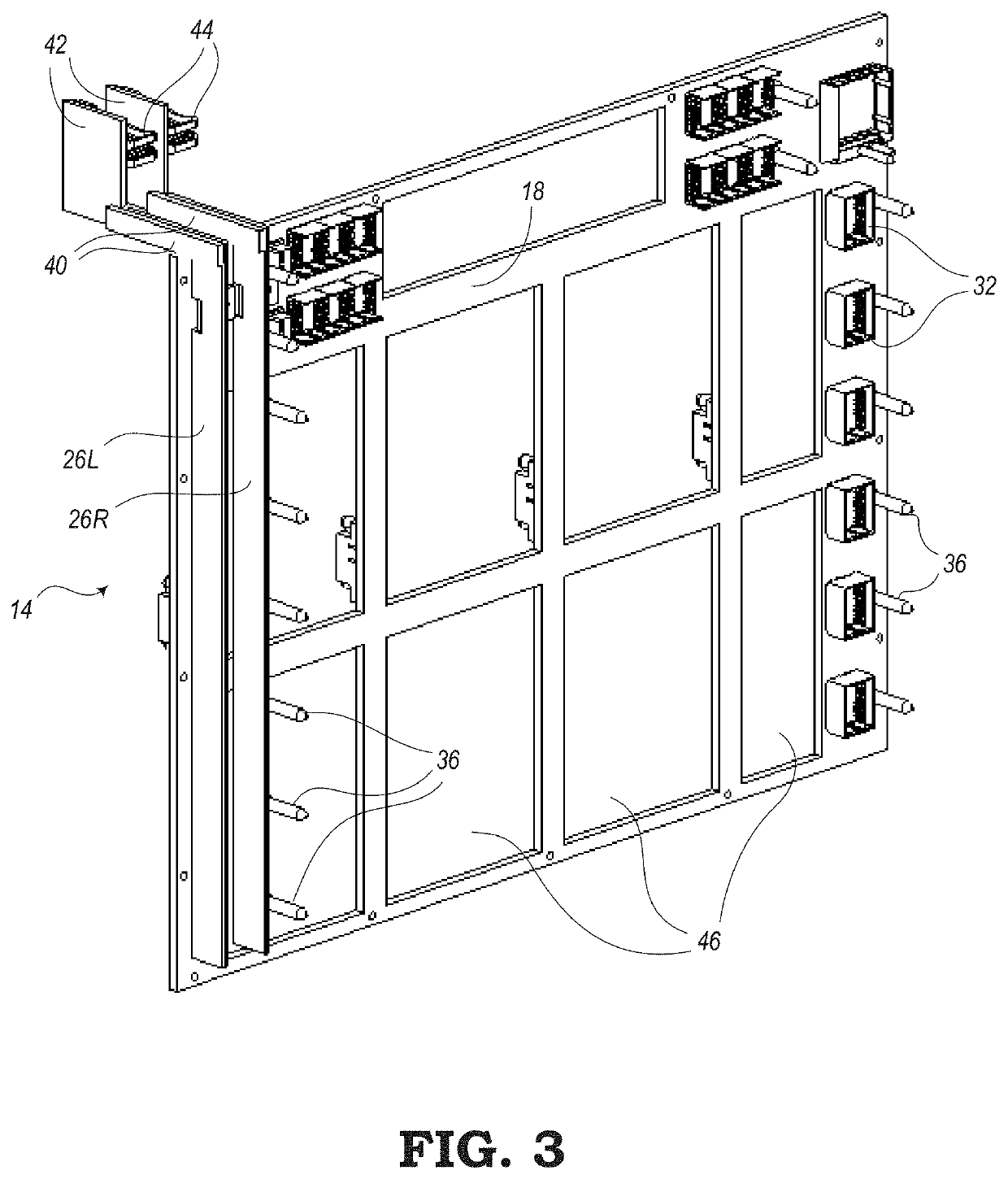

[0062]The alignment block 60 may be configured to provide alignment for power connectors (e.g., power connectors 22) on a circuit board (e.g., circuit board 16) to guide electrical contacts of the power connectors through slots in the alignment block 60 to allow the electrical contacts to be electrically engaged with the conductive strips 26 for providing power to the circuit board. In addition to alignment functions, the alignment block 60 may be configured to provide protective functions for protecting users from electrical shock (or electrocution) from the electrical power being carried by the conductive strips 26 of the busbar system ...

third embodiment

[0084]FIG. 20 is a close-up front perspective view of the third busbar assembly 170 shown in FIG. 19 to show details of the alignment blocks 174 according to a Again, the power connectors 178 of the circuit board 176 are shown as being fully installed in order to connect to the busbars (e.g., conductive strips 172L, 172R). Electrical contact is made through one of the alignment blocks 174 when the circuit board 176 is fully inserted onto the non-conductive substrate 182 for power and signal connection. FIG. 21 shows a front view of the alignment blocks 174 of the busbar assembly 170 shown in FIG. 19 accurately attached to the non-conductive substrate 182.

[0085]FIG. 22 is a front perspective view of one of the alignment blocks 174 shown in FIG. 19 and FIG. 23 is a back perspective view of the alignment block 174. As mentioned above, the alignment block 174 may be configured to provide alignment for power connectors 178 on a circuit board 176 to guide electrical contacts of the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com