High voltage edge termination structure for power semicondcutor devices and manufacturing method thereof

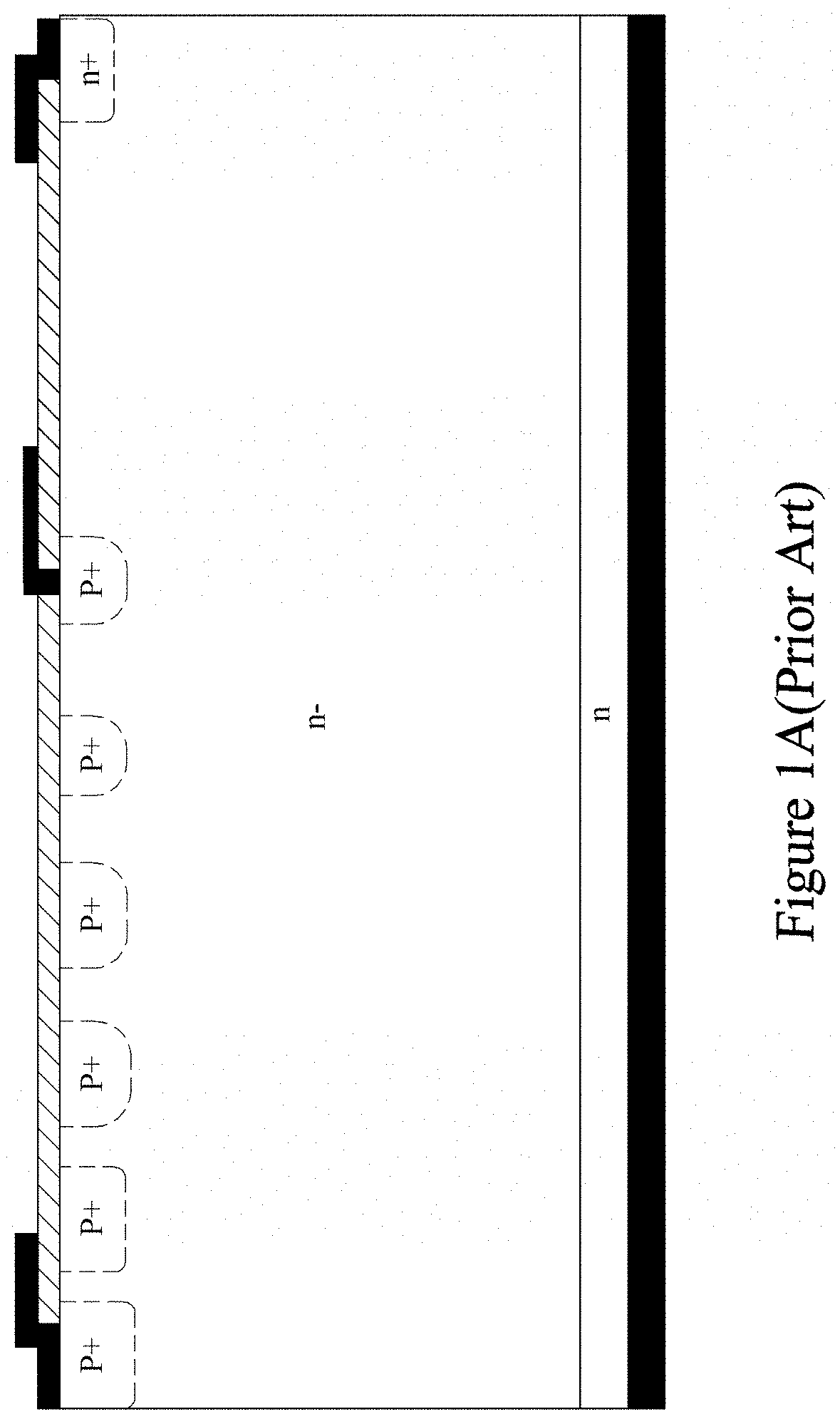

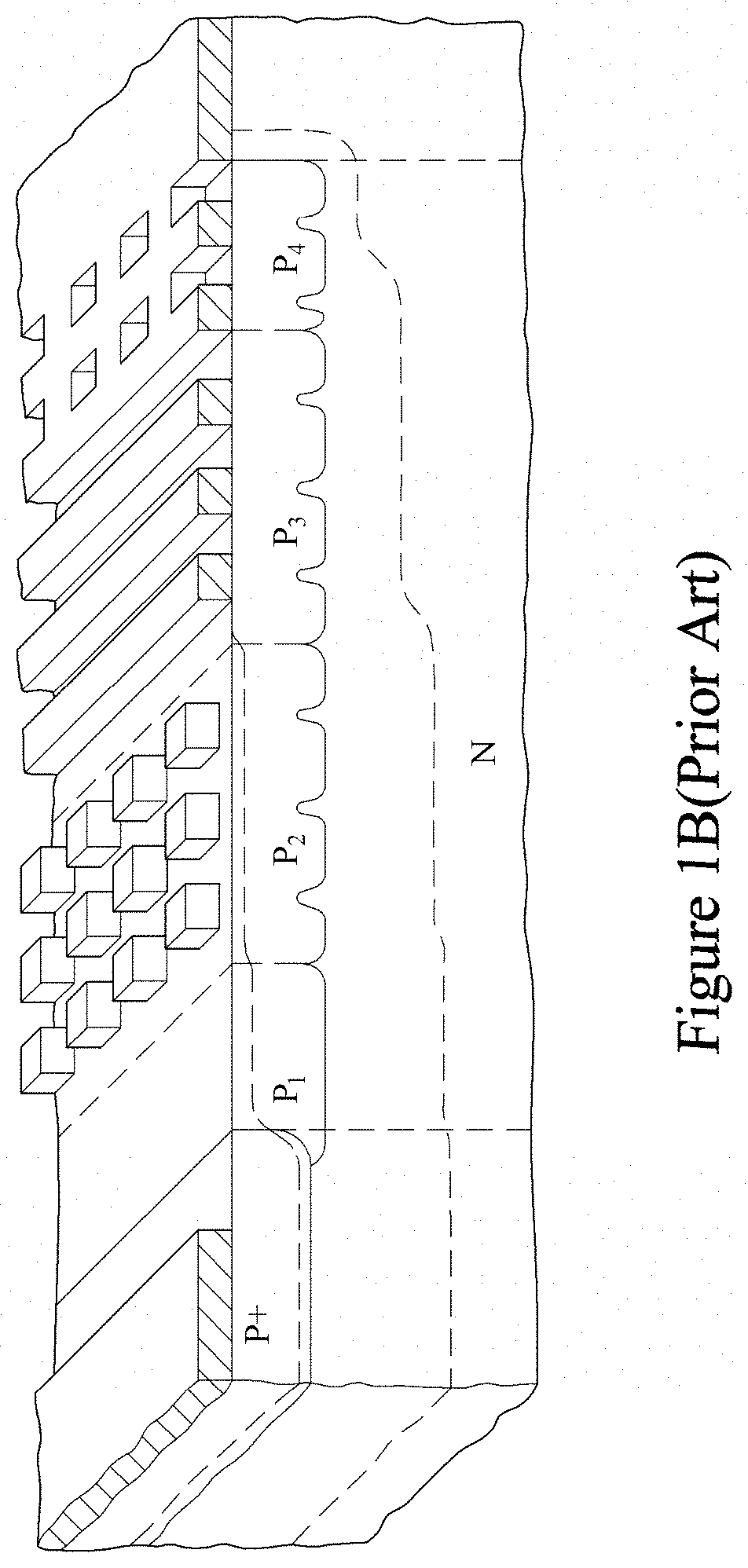

a technology of edge termination structure and power semiconductor, applied in the direction of semiconductor devices, basic electric elements, electrical apparatus, etc., can solve the problems of low applied voltage breakdown of devices, markedly sensitive jte structures to surface charge variations, and low voltage. , to achieve the effect of increasing the tolerance to surface charge, reducing the area of the structure, and high voltag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

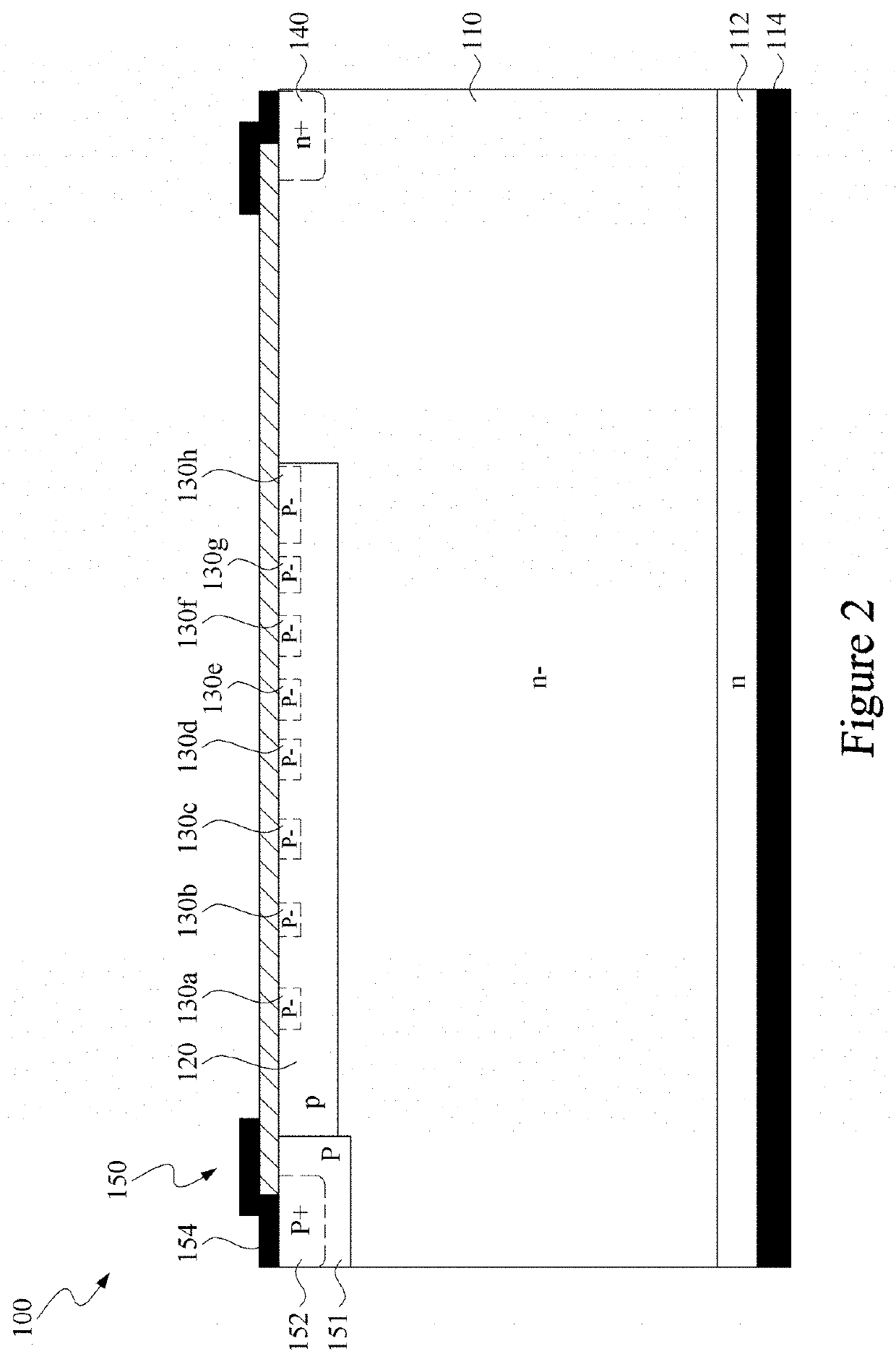

[0052]Please referring to FIG. 2, a high voltage edge termination structure featuring a laterally modulated JTE structure provided in accordance with the present invention will be discussed.

[0053]As illustrated in FIG. 2, the high voltage edge termination structure 100 comprises an N-type semiconductor body 110, a P-type JTE region 120, a plurality of P-type lightly doped regions 130a-130h, and an N-type heavily doped channel stop region 140.

[0054]There is an N-type semiconductor layer 112 with a doping concentration higher than that of the N-type semiconductor body 110 formed on a lower surface of the N-type semiconductor body 110. The N-type semiconductor layer 112 is utilized for reducing contact resistance between the N-type semiconductor body 110 and a cathode electrode 114 of the power semiconductor device.

[0055]The P-type JTE region 120 is formed in the top portion of the N-type semiconductor body 110. The P-type JTE region 120 is adjacent to the active region 150 of the powe...

second embodiment

[0066]Referring to FIG. 3, a high voltage edge termination structure featuring a JTE structure with field plates provided in accordance with the present invention will be discussed.

[0067]As illustrated in FIG. 3, the high voltage edge termination structure 200 comprises an N-type semiconductor body 210, a P-type JTE region 220, an N-type heavily doped channel stop region 240, and a plurality of field plates 260 (three field plates are shown).

[0068]There is an N-type semiconductor layer 212 with a doping concentration higher than that of the N-type semiconductor body 210 formed on a lower surface of the N-type semiconductor body 210. The N-type semiconductor layer 212 is utilized for reducing contact resistance between the N-type semiconductor body 210 and a cathode electrode 214 of the power semiconductor device.

[0069]The P-type JTE region 220 is formed in the top portion of the N-type semiconductor body 210, i.e. the portion close to the upper surface thereof. The P-type JTE region...

third embodiment

[0073]Referring to FIG. 4, a high voltage edge termination structure featuring a JTE structure with depletable guard rings and field plates provided in accordance with the present invention will be discussed.

[0074]As illustrated in FIG. 4, the high voltage edge termination structure 300 comprises an N-type semiconductor body 310, a P-type JTE region 320, an N-type heavily doped channel stop region 340, a plurality of field plates 360 (three field plates are shown), and a plurality of P-type depletable guard rings 370 (four depletable guard rings are shown).

[0075]There is an N-type semiconductor layer 312 with a doping concentration higher than that of the N-type semiconductor body 310 formed on a lower surface of the N-type semiconductor body 310. The N-type semiconductor layer 312 is utilized for reducing contact resistance between the N-type semiconductor body 310 and a cathode electrode 314 of the power semiconductor device.

[0076]The P-type JTE region 320 is formed in top portion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltages | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com