Monodisperse Cu2O single crystal solid sphere with controllable particle size and preparation method thereof

A monodisperse, solid sphere technology, applied in the direction of copper oxide/copper hydroxide, nanotechnology, etc., can solve problems that have not been reported before, and achieve the effect of expanding the application range and precisely controlling the particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

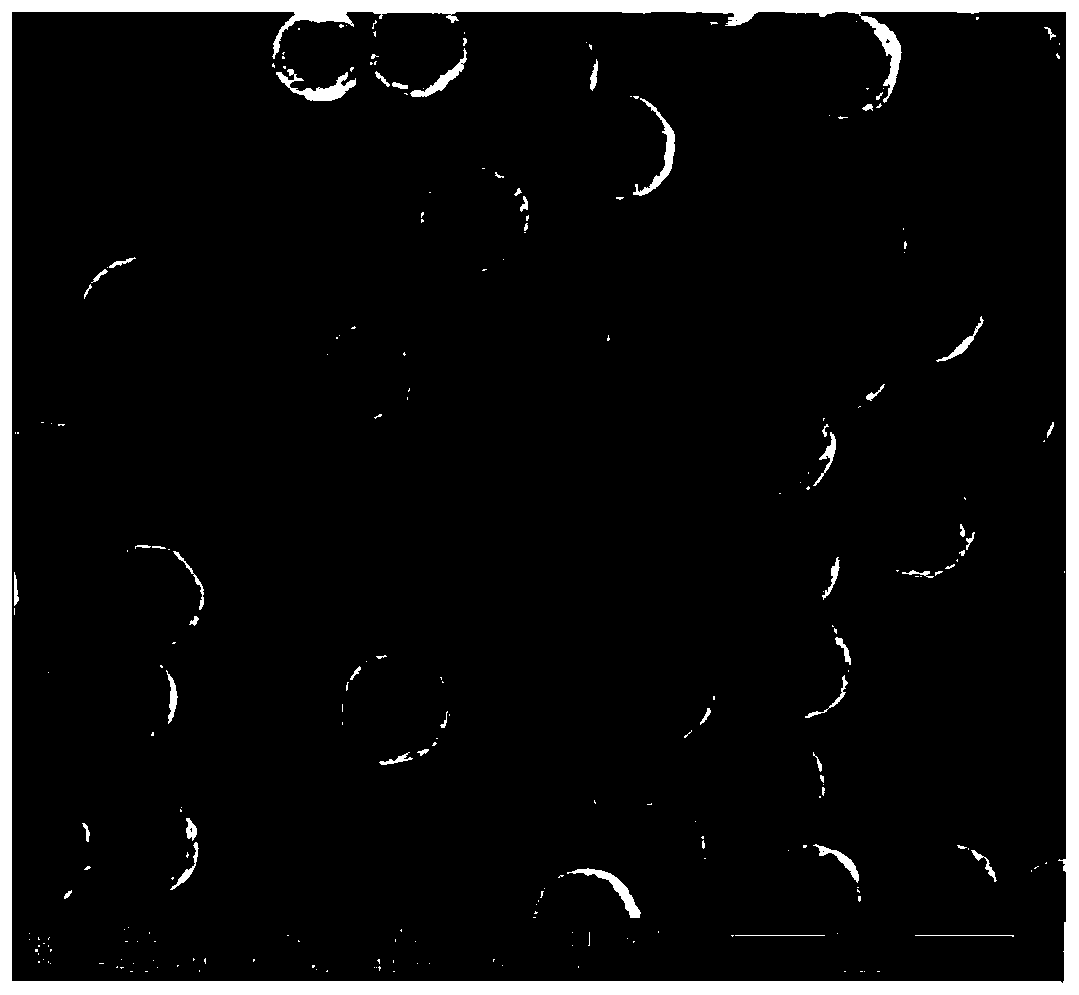

[0027] Add copper source 13.4mM, small molecule ligand 26.8mM sodium citrate dihydrate, polyvinylpyrrolidone (molecular weight Mw=30000) 2.3mM into the mixed solvent of water and polyol (ethylene glycol) (ethylene glycol and water The mass ratio is 3:10), add 20mL of NaOH solution to the mixed solution, and the concentration is 0.5M; at a temperature of 20°C; add 7mL, 0.12M ascorbic acid to the above mixed solution, react for 20min, and add to the mixed solution Add 8mL of ascorbic acid together, react for 1h, centrifuge to separate the precipitate, and dry the product under vacuum at 60°C to obtain uniform single crystal cuprous oxide solid microspheres with a particle size of 170nm, as figure 1 shown. Use 170nm monodispersed cuprous oxide single crystal solid balls as building units to build an amorphous structure, and carry out reflectance spectrum tests and structural color photos as shown in Figure 5 As shown, the reflection peak position is 635nm, and the structure is ...

Embodiment 2

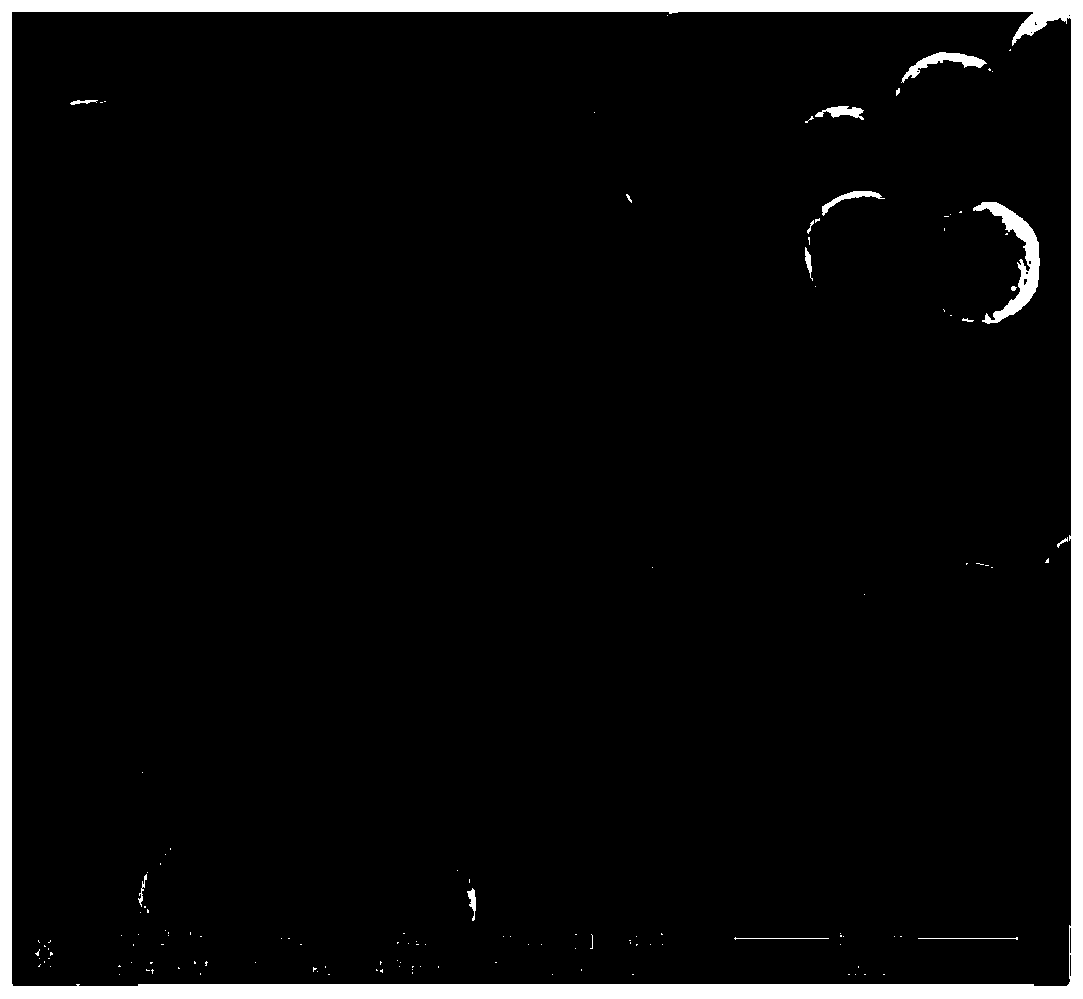

[0029]Copper source 13.4mM, small molecule ligand 16.2mM disodium edetate), polyvinylpyrrolidone (molecular weight Mw=40000) 2.3mM joins in the mixed solvent of water and glycerol (glycerol and water The mass ratio is 2:5), add 20mL of NaOH solution to the mixed solution, the concentration is 0.5M; under the condition of temperature of 60°C; add 7mL, 0.12M glucose dropwise to the above mixed solution under vigorous stirring, and react After 10 minutes, add 8 mL of glucose to the mixed solution, react for 1 hour, centrifuge to separate the precipitate, and dry the product under vacuum at 60°C to obtain monodisperse single-crystal cuprous oxide solid microspheres with a particle size of 200 nm. ,Such as figure 2 shown.

Embodiment 3

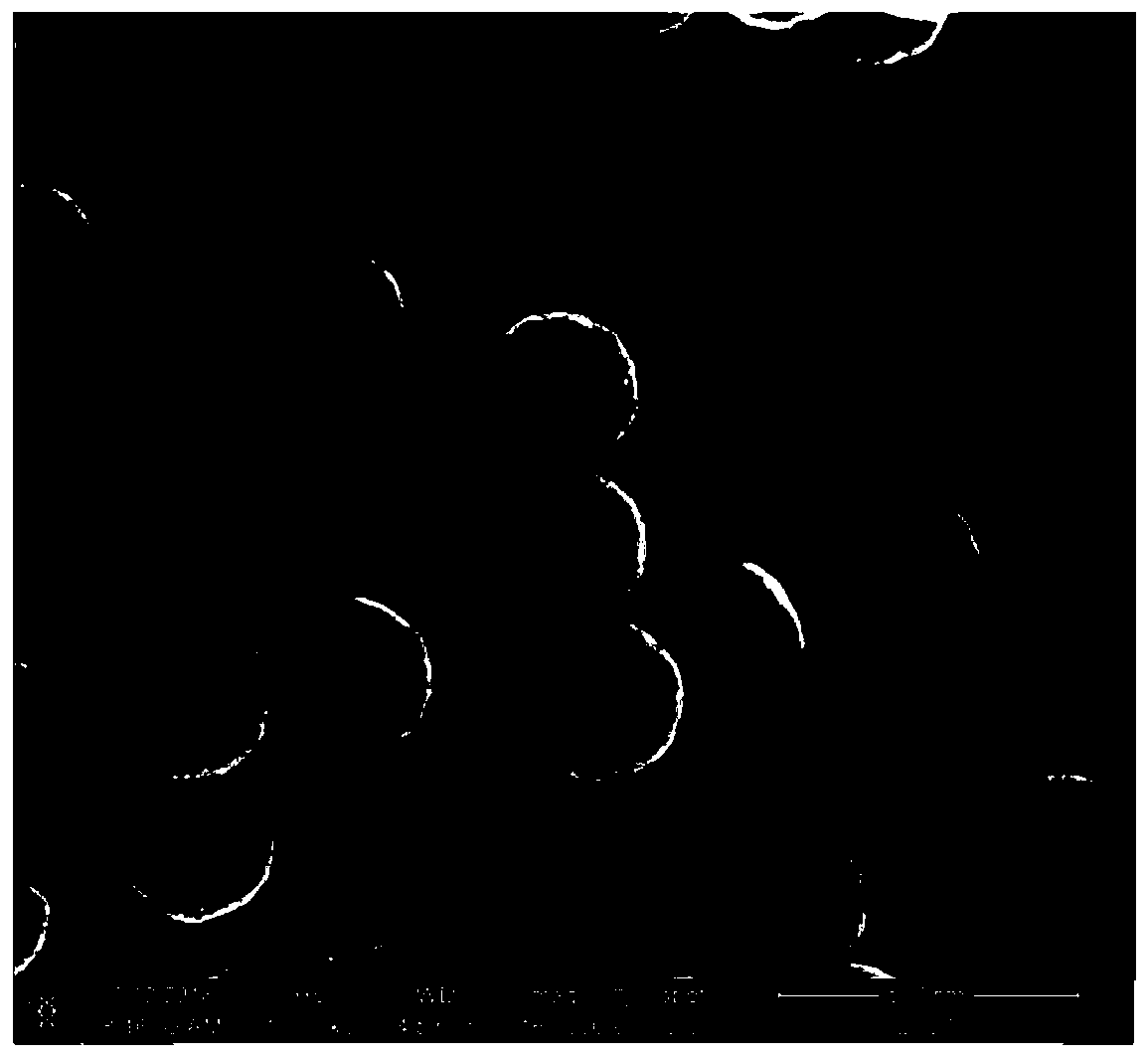

[0031] Copper source 13.4mM, small molecule ligand 18.7mM pentasodium diethylenetriaminepentaacetic acid (, polyvinylpyrrolidone (molecular weight Mw=10000) 2.3mM is added in the mixed solvent of water and neopentyl glycol ethylene glycol (new The mass ratio of pentylene glycol to water is 7:10), add 20mL of NaOH solution dropwise to the mixed solution, and the concentration is 0.5M; the temperature is under the condition of 80°C; add 7mL dropwise to the above mixed solution, 0.12M Glucose, after reacting for 10 minutes, add 8 mL of glucose to the mixed solution together, react for 1 hour, centrifuge to separate the precipitate, and dry the product under vacuum at 60°C to obtain a monodisperse single crystal cuprous oxide solid with a particle size of 270nm Microspheres, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com