Preparation process of nanometer zinc oxide with antibacterial performance

A nano-zinc oxide and preparation technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the difficulty of high industrial production, complex process technology, low product purity, etc. problem, to achieve the effect of promoting stability, improving antibacterial performance and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

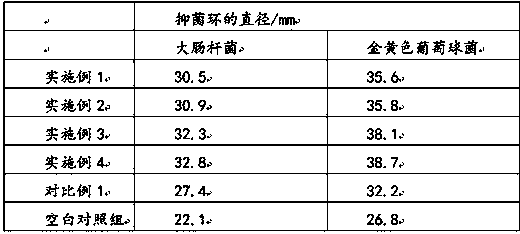

Examples

Embodiment 1

[0059] A preparation process of nano-zinc oxide with antibacterial properties, comprising the following steps:

[0060] (1) Preparation of colloid a

[0061] Prepare a calcium chloride-ethanol-water mixed solution, add sodium polyacrylate and silk fibroin to the mixed solution, heat to 35°C, and stir at 1500 r / min for 1 hour to obtain colloid a; the sodium polyacrylate and silk The mass ratio of fibroin is not higher than 1:30; the mass ratio of calcium chloride, ethanol and water in the calcium chloride-ethanol-water mixed solution is 0.8:3:10; silk fibroin accounts for the calcium chloride-ethanol-water mixed solution The quality score of 7.2%. The mass ratio of sodium polyacrylate to silk fibroin is 1:35;

[0062] (2) Preparation of colloid b

[0063] Add sodium hydroxide and cetyltrimethylammonium bromide to the isopropanol solution in turn, stir at 500r / min for 30min, and then add dropwise to the zinc acetate solution, add dropwise while stirring, dropwise add After c...

Embodiment 2

[0069] A preparation process of nano-zinc oxide with antibacterial properties, comprising the following steps:

[0070] (1) Preparation of colloid a

[0071] Prepare a calcium chloride-ethanol-water mixed solution, add sodium polyacrylate and silk fibroin to the mixed solution, heat to 38°C, and stir at 1500 r / min for 1 hour to obtain colloid a; the sodium polyacrylate and silk The mass ratio of fibroin is not higher than 1:30; the mass ratio of calcium chloride, ethanol and water in the calcium chloride-ethanol-water mixed solution is 1:3:10; silk fibroin accounts for the calcium chloride-ethanol-water mixed solution The quality score of 7.6%. The mass ratio of sodium polyacrylate to silk fibroin is 1:40;

[0072] (2) Preparation of colloid b

[0073] Add sodium hydroxide and cetyltrimethylammonium bromide to the isopropanol solution in turn, stir at 500r / min for 30min, and then add dropwise to the zinc acetate solution, add dropwise while stirring, dropwise add After com...

Embodiment 3

[0079] A preparation process of nano-zinc oxide with antibacterial properties, comprising the following steps:

[0080] (1) Preparation of colloid a

[0081] Prepare a calcium chloride-ethanol-water mixed solution, add sodium polyacrylate and silk fibroin to the mixed solution, heat to 36°C, and stir at 1500 r / min for 1 hour to obtain colloid a; the sodium polyacrylate and silk The mass ratio of fibroin is not higher than 1:30; the mass ratio of calcium chloride, ethanol and water in the calcium chloride-ethanol-water mixed solution is 1.0:10; silk fibroin accounts for the mass of the calcium chloride-ethanol-water mixed solution The score was 7.3%. The mass ratio of sodium polyacrylate to silk fibroin is 1:37;

[0082] (2) Preparation of colloid b

[0083] Add sodium hydroxide and cetyltrimethylammonium bromide to the isopropanol solution in turn, stir at 500r / min for 30min, and then add dropwise to the zinc acetate solution, add dropwise while stirring, dropwise add Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com