Automatic shut-off for water treatment system

a water treatment system and automatic shut-off technology, applied in the direction of filtration separation, separation processes, instruments, etc., can solve the problems of uncontrollable release of water from the system, significant flood damage to the building or structure in which the water treatment system is located, and system failures, so as to prevent further water damage and ensure the effect of shut-off reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. Construction Overview

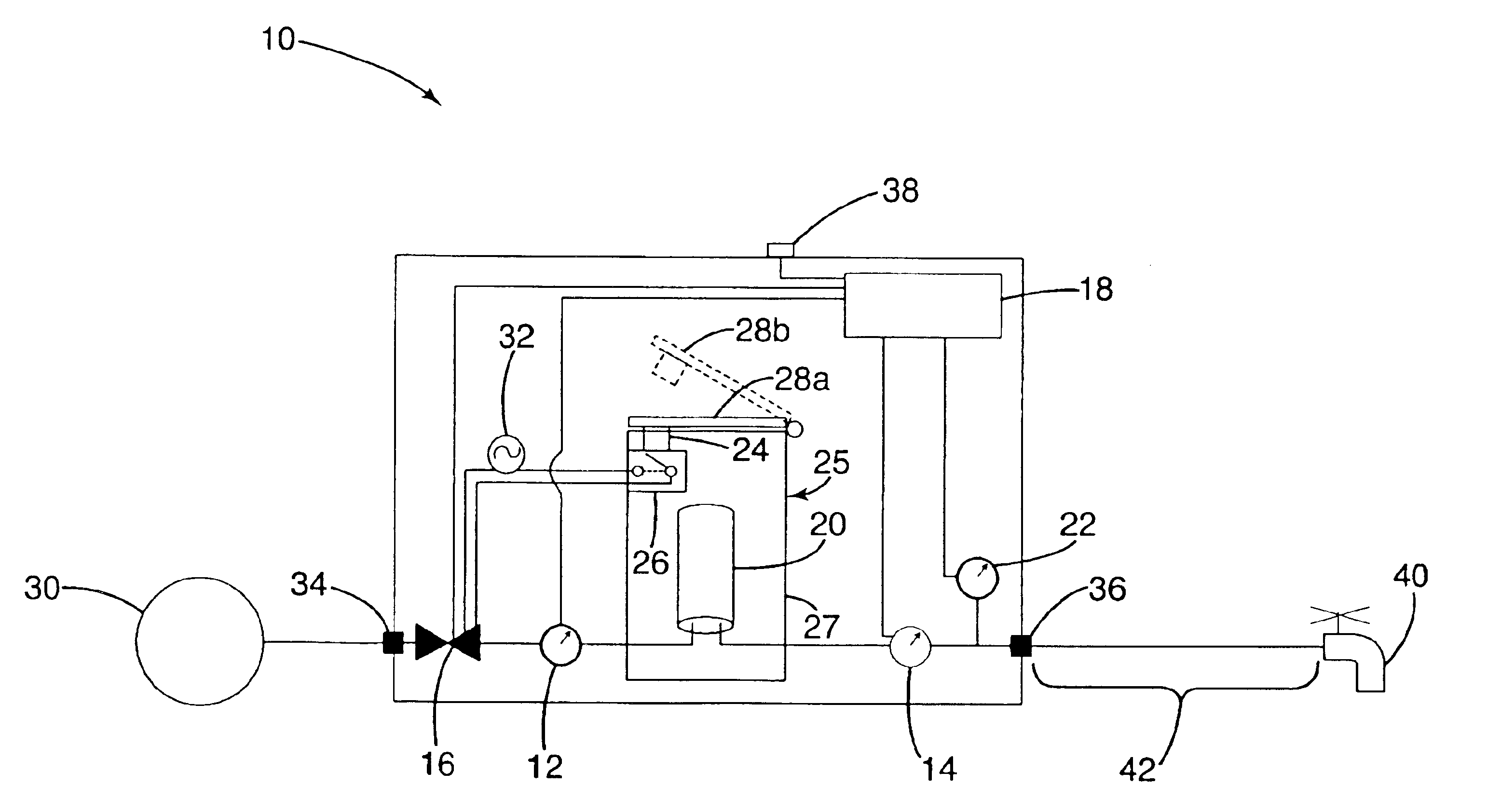

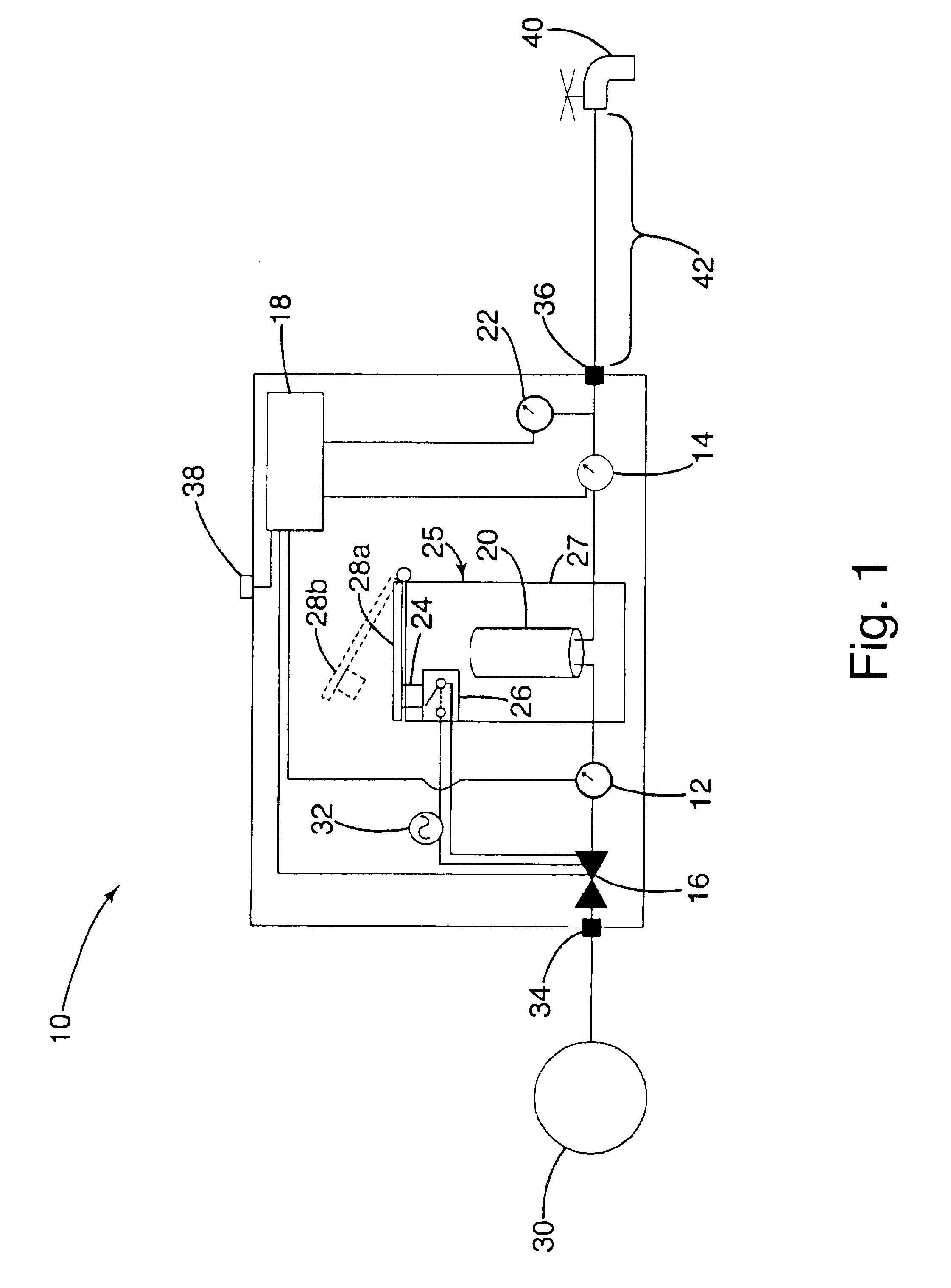

[0017]A water treatment system manufactured in accordance with an embodiment of the present invention is shown in FIG. 1 and generally designated 10. The water treatment system is in fluid communication with a water supply 30 and a point of use 40, which for example, may be a faucet or multiple faucets within a building or distribution system. Plumbing system 42 provides the communication between the water treatment system 10 and the faucet 40.

[0018]The water treatment system 10 generally includes in an inflow control valve 16, inflow sensor 12, a water treatment device 25, outflow sensor 14 and a pressure sensor 22. The inflow control valve 16 is controlled by the processor 18. Inflow 12 and outflow 14 sensors, as well as pressure sensor 22 are in communication with the processor 18 so that the processor may monitor different operating parameters as described below. The inflow control valve 16, inflow sensor 12, water treatment device 25, outflow sensor 14 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com