Layered sheet construction for wastewater treatment

a wastewater treatment and layered technology, applied in biological water/sewage treatment, filtration separation, separation processes, etc., can solve the problems of hygienic problems, installation and operation of plants using such processes, and large equipment requirements, and achieve easy and economical manufacturing, reduce the amount of microorganisms on the surface of the layer, and contribute to the durability of the apparatus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

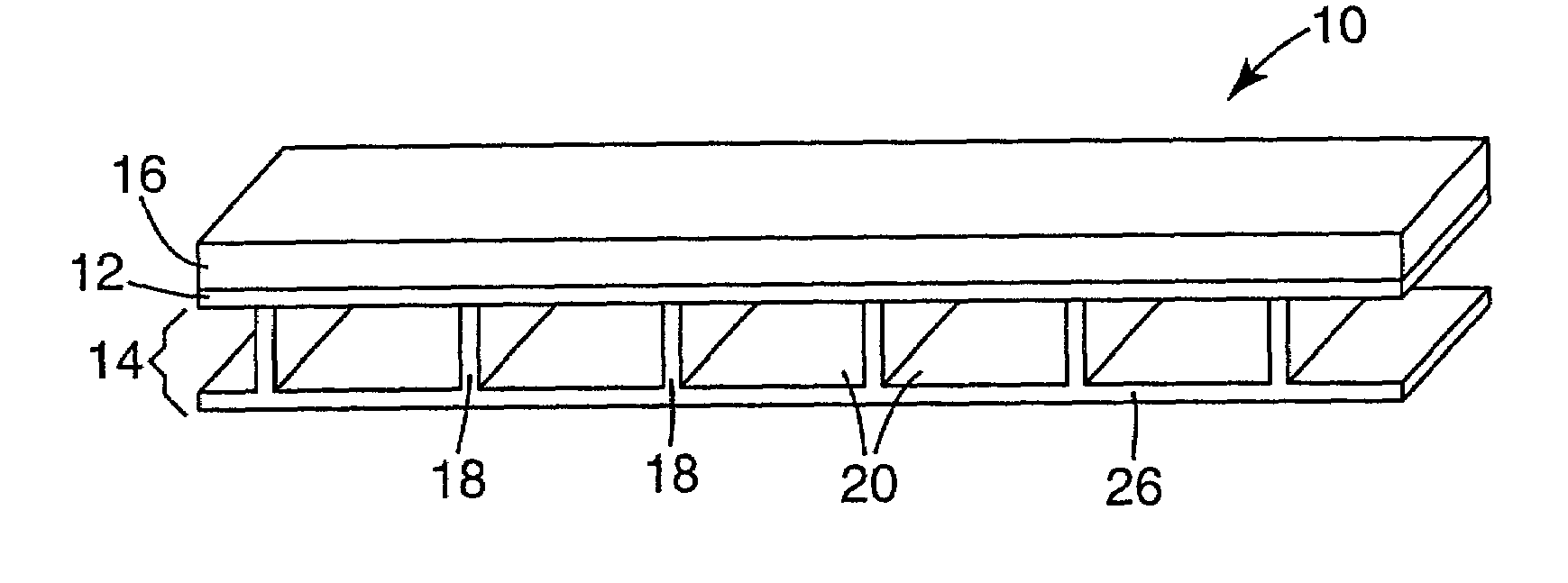

[0103]Example 1 illustrates an apparatus of the invention that was made by forming a gas delivery layer and affixing a gas permeable layer to the textured surface of the gas delivery layer.

[0104]A melt processible ethylene-polypropylene copolymer (7C55H available from Dow Chemical, Midland, Mich.) was fed into a single screw extruder (supplied by Davis Standard Corporation, Pawcatuk, Conn.) to form a gas delivery layer having one smooth surface (base layer) and one textured surface. The extruder had a diameter of 6.35 centimeters (cm) (2.5 in), a length / diameter (L / D) ratio of 24 / 1, and a temperature profile that steadily increased from approximately 177 to 232° C. (350 to 450° F.). The polymer was continuously discharged at a pressure of at least 689 kPa (100 psi) through a neck-tube heated to 232° C. (450° F.) and into a 20.32 cm (8 in.) wide MASTERFLEX™ LD-40 film die (supplied by Production Components, Eau Claire, Wis.), maintained at a temperature of 232° C. (450° F.). The die ...

example 2

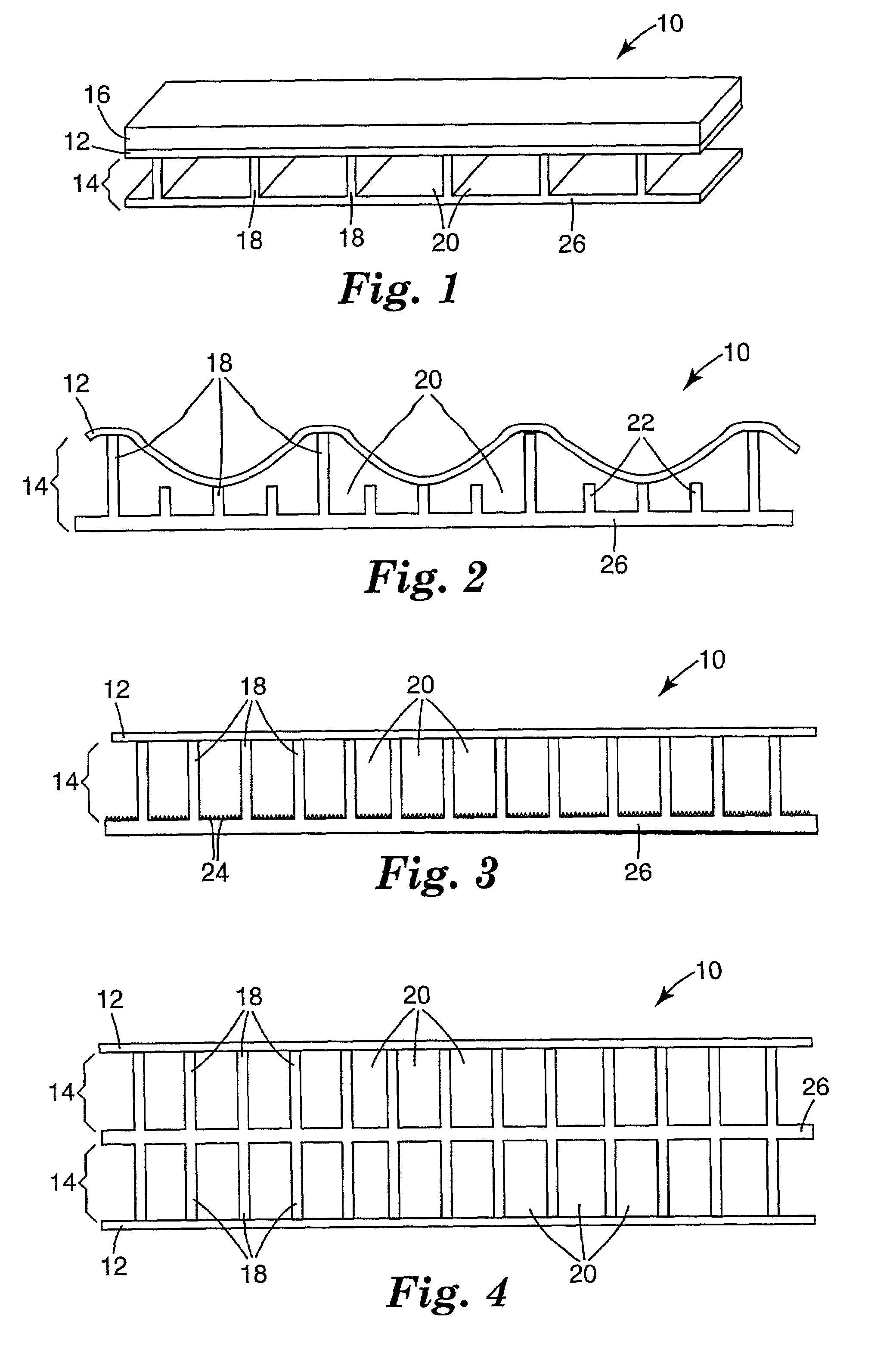

[0105]Example 2 illustrates a gas delivery layer having textured features (walls) on both sides (a dual gas delivery layer).

[0106]A gas delivery film was made in a manner similar to Example 1 except the smooth surface of the gas delivery layer (surface without the walls) was melt-affixed to the smooth surface of another previously made gas delivery layer. The dual gas delivery layer that resulted is like that one shown in FIG. 4 and had a base thickness of about 355 μm (14 mils). Each wall that extended from the base had a height of 1.2 mm (46 mils), a width of 0.4 mm (16 mils) and a center-to-center spacing of 1.0 mm (40 mils).

[0107]The resulting gas delivery layer was suitable for adhering gas permeable layers to both textured surfaces (walls) by lamination techniques to make a layered sheet construction having two surfaces on which to grow biofilms.

example 3

[0108]Example 3 illustrates another method of making a gas delivery layer having textured features on both sides (dual gas delivery layer).

[0109]A gas delivery layer was made in a manner similar to Example 1 except the extruder film die was configured to form walls, with hook-like protrusions, that extended about perpendicularly from both surfaces of the base layer of the gas delivery layer, as shown in FIG. 5. The dual gas delivery layer that resulted was drop-cast into a water bath to quench it. The dual gas delivery layer had a base thickness of about 254 μm (10 mils). Each wall that extended from the base had a height that alternated between 1.0 mm (40 mils) and 0.7 mm (27 mils), a width of 178 μm (7 mils) and a center-to-center spacing of 1.3 mm (50 mils). The hook-like protrusions at the end of each wall had widths of 0.7 mm (28 mils). The wall position on one surface were staggered when compared with the positions of the walls on the other surface such that one wall on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore sizes | aaaaa | aaaaa |

| pore sizes | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com