Optical module and optical transmission device

a technology of optical modules and optical transmission devices, applied in the direction of optical elements, instruments, optical waveguide light guides, etc., can solve the problems of degrading coupling efficiency, narrow space between mounting parts, and difficult optical axis alignment, so as to improve coupling efficiency and facilitate optical axis alignment of surface light emitting elements and optical waveguides. , the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

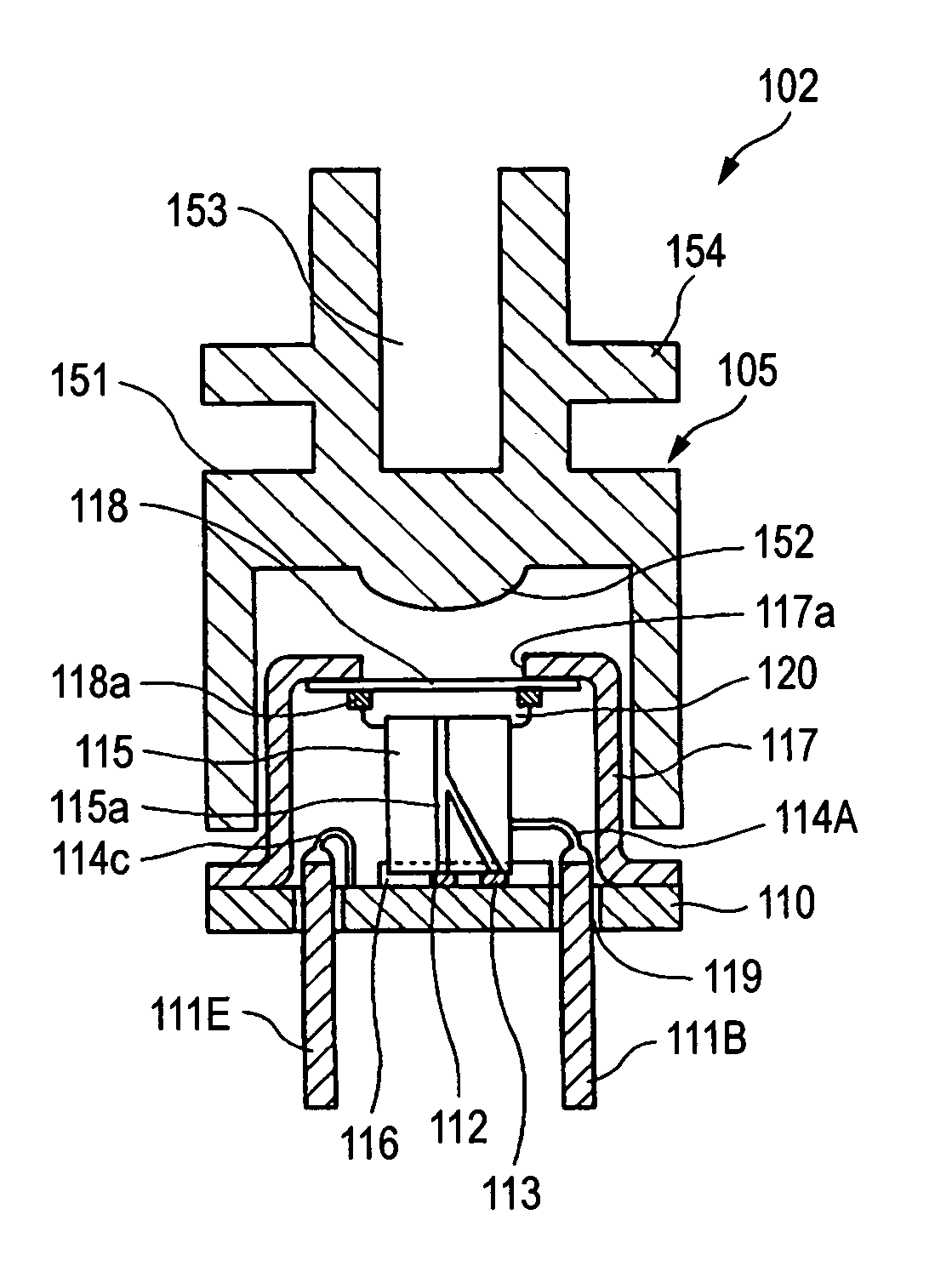

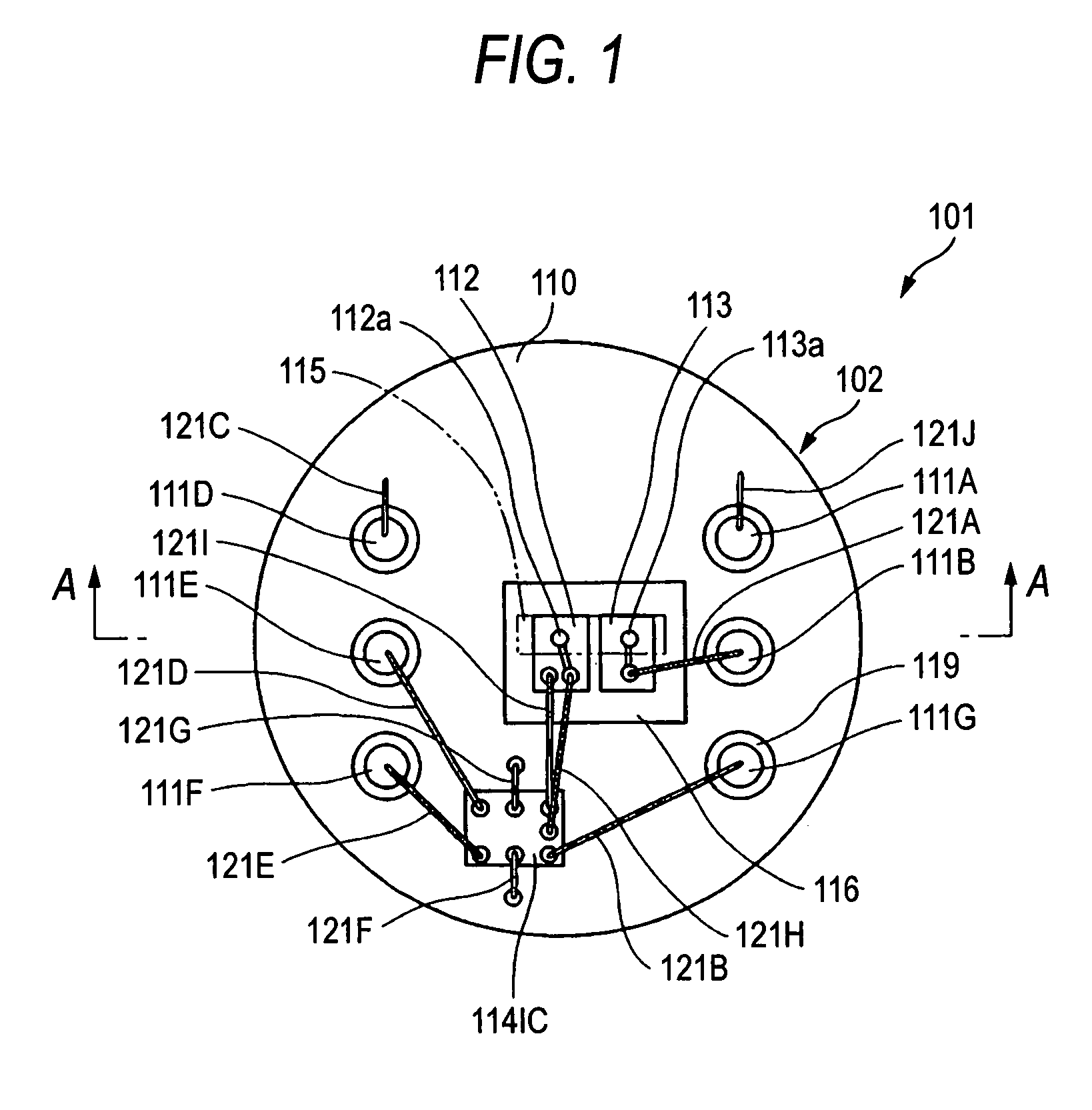

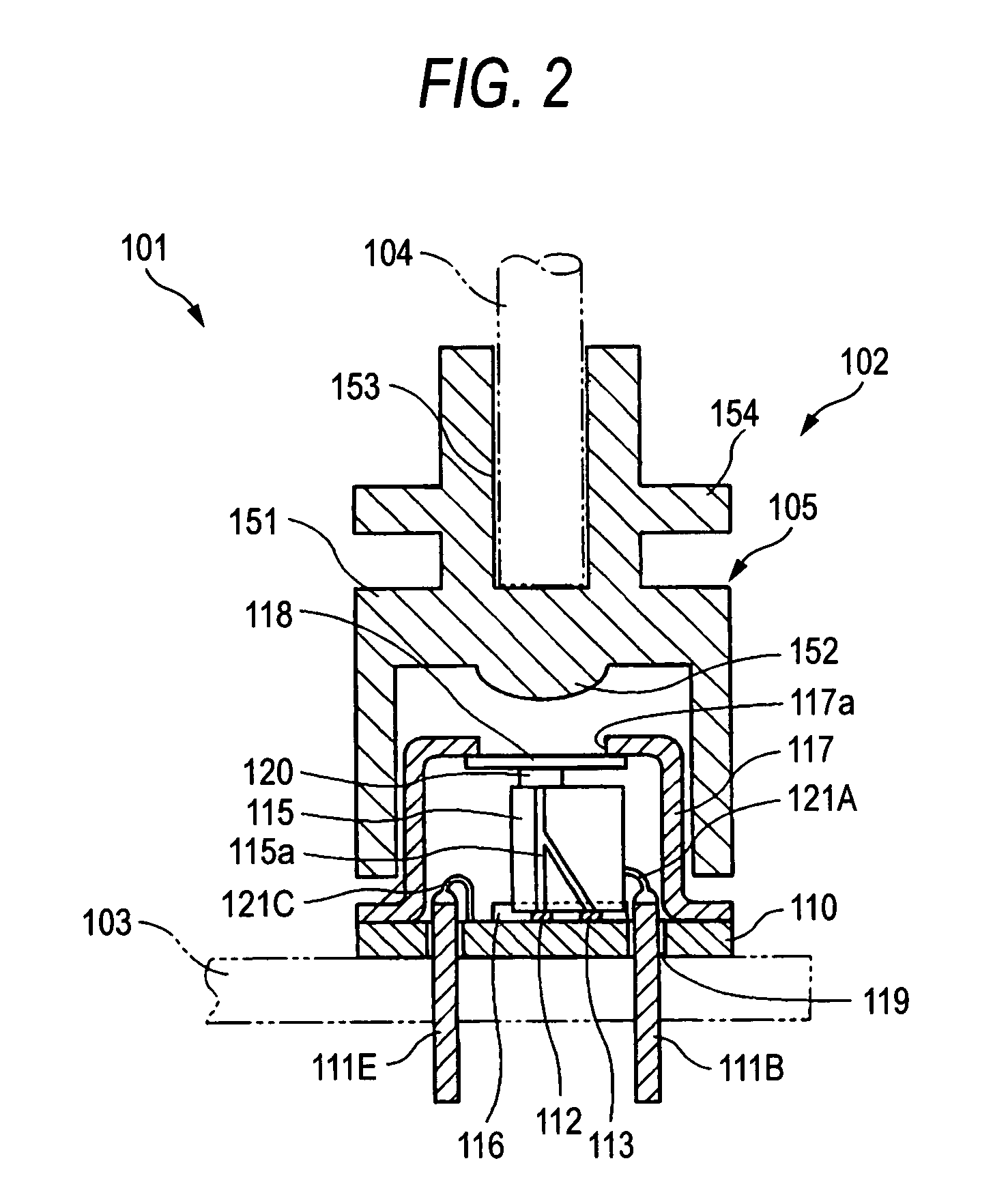

[0033]FIG. 1 is a plan view of an optical transmission device according to a first embodiment of the present invention and FIG. 2 is a cross sectional view taken along a line A—A in FIG. 1.

[0034]The optical transmission device 101 is configured by an optical module 102, to which an optical fiber 104 is connected as an optical transmission medium, and a circuit board 103, on which the optical module 102 is mounted.

[0035]The optical module 102 includes a metal stem 110 as a base portion, a light receiving element 112 and a light emitting element 113 provided on the metal stem 110 as a surface type optical element, an IC 114 for amplifying an output signal of the light receiving element 112, an optical waveguide 115 optically coupled with the light receiving element 112 and the light emitting element 113, a sub mount 116 as a fixing member for positioning and holding the light receiving element 112, the light emitting element 113 and the optical waveguide 115, a metal cap 117 having an...

second embodiment

[0060]FIG. 5 shows an optical module according to the second embodiment of the present invention. The second embodiment is similar to the optical module 102 of the first embodiment except that a gel-type refractive index matching agent is used as the fixing member 120 and the fixing member 120 fills a space between the cap 117 and the optical waveguide 115.

[0061]The gel-type refractive index matching agent may be, for example, gel-type silicone resin. The gel-type refractive index matching agent has refractive index similar to that of the optical waveguide 115 and the transparent window 118 and a different in refractive index between the fixing member 120 and the optical waveguide 115 and the transparent window 118 is preferably within 0.1 in view of the transmission loss due to Fresnel reflection. It is more preferable that the difference is within 0.05. Since the gel-type refractive index matching agent is a jelly, it is possible to obtain an enough adhering force with respect to ...

third embodiment

[0063]FIG. 6 shows an optical module according to the third embodiment of the present invention and FIGS. 7A, 7B shows the position and configuration of the fixing member shown in FIG. 6. As shown in FIGS. 6, 7A, and 7B, the third embodiment is substantially the same as the optical module 102 of the first embodiment except that the fixing member 120 of the third embodiment is an elastic member and is provided in a position in the vicinity of the center portion of the end face of the optical waveguide 115 and spaced apart from the position of the light guide portion 115a.

[0064]As the elastic member, transparent silicon rubber may be used. The elastic member has a circular configuration as shown in FIG. 7A or an ellipsoidal configuration as shown in FIG. 7B. In either case, the fixing member 120 is arranged such that it exerts elastic force (pressing force) on the optical waveguide 115 and the transparent window 118.

[0065]The elastic member may be provided on the side of the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com