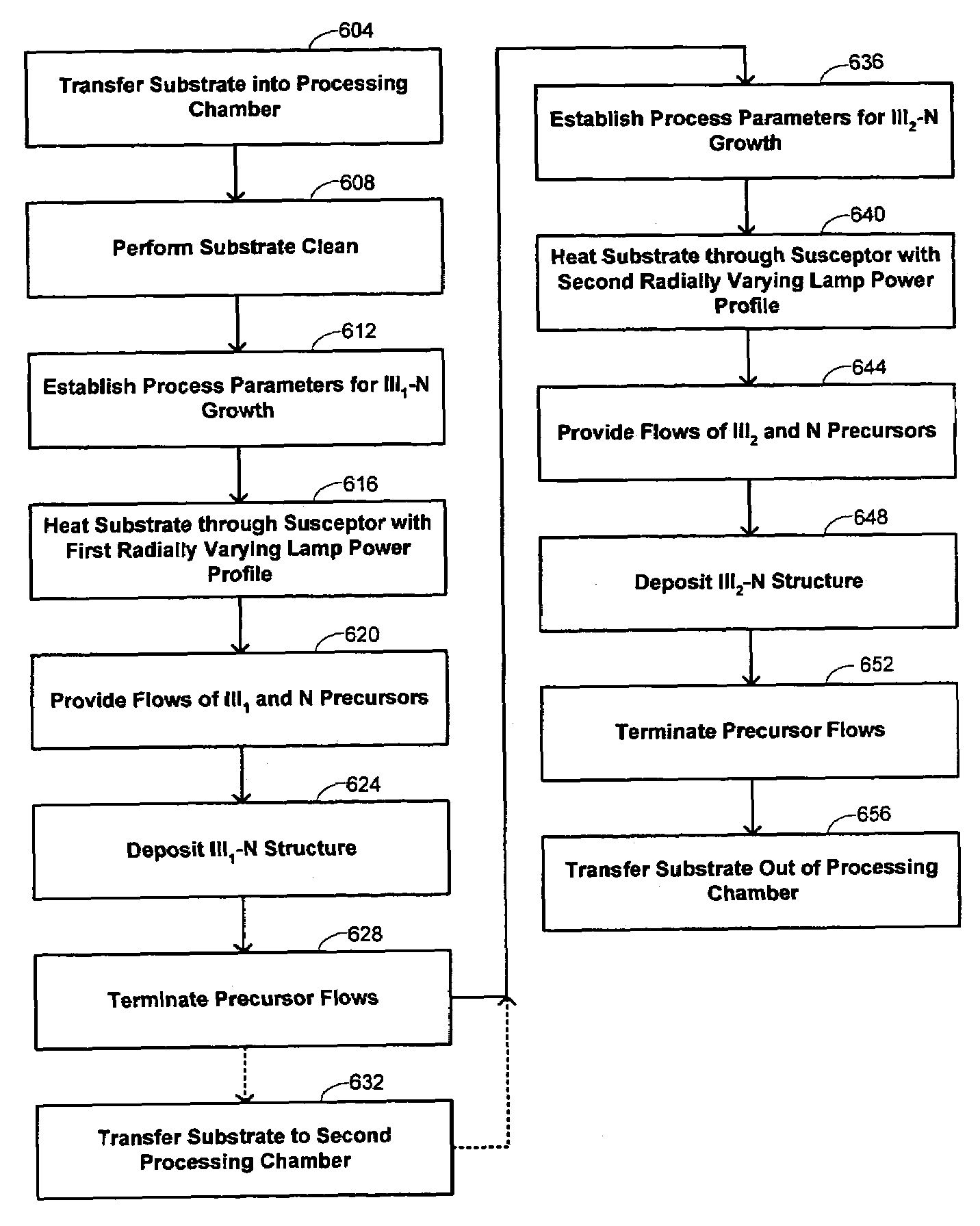

Radial temperature control for lattice-mismatched epitaxy

a technology of lattice and epitaxy, applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas growth, etc., can solve the problems of poor luminescence of devices, impeded practical fabrication, and difficulty in efficient p-doping of such materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

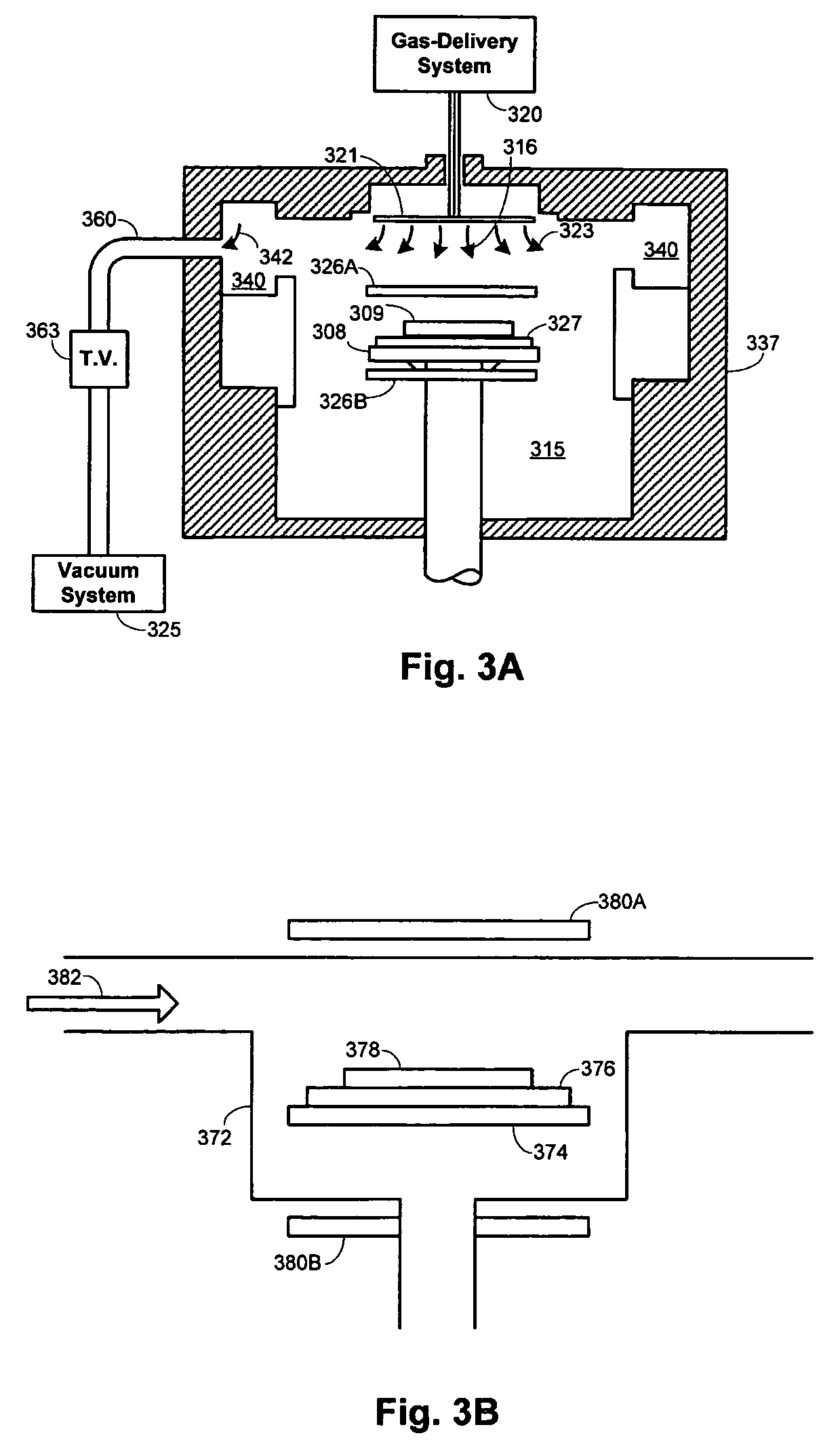

Method used

Image

Examples

Embodiment Construction

1. Overview

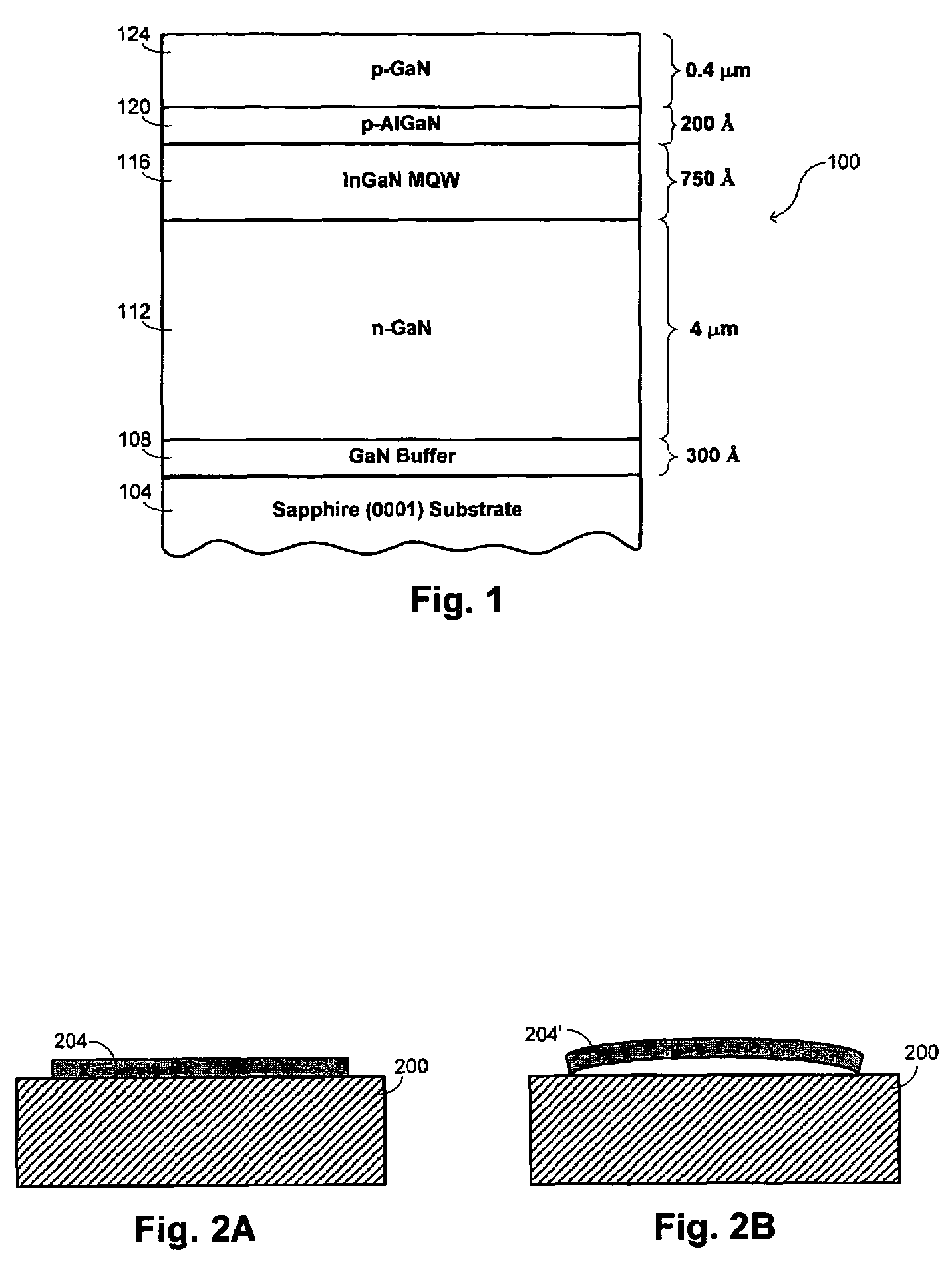

[0021]One of the difficulties mentioned above in fabricating nitride-based structures such as GaN structures is the accommodation of generally high thermal requirements for growth of GaN. Historically, this made the identification of a suitable substrate difficult, with the art more recently focusing on ways in which the use of sapphire Al2O3 may be accommodated. Sapphire is not an ideal substrate because there is a significant lattice mismatch with deposited nitride layers; in the specific case of GaN, this lattice mismatch is approximately 15%. While the use of a nitride buffer layer has been helpful in accommodating the lattice mismatch, both the lattice mismatch and other physical differences between the sapphire substrate and overlying nitride layer result in distortions of resulting structures.

[0022]One typical nitride-based structure is illustrated in FIG. 1 as a GaN-based LED structure 100. It is fabricated over a sapphire (0001) substrate 104. An n-type GaN layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com