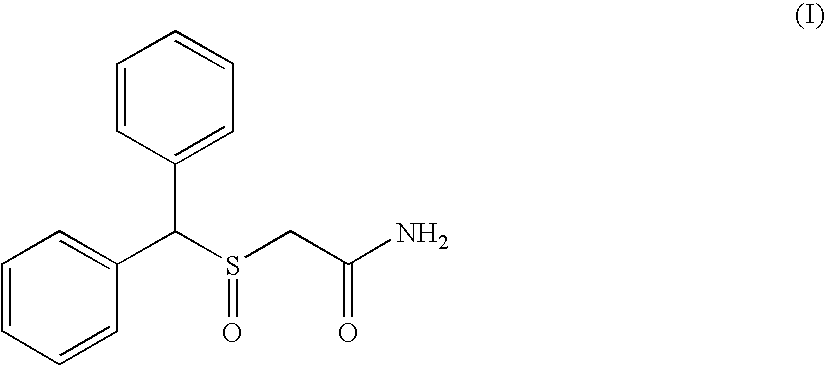

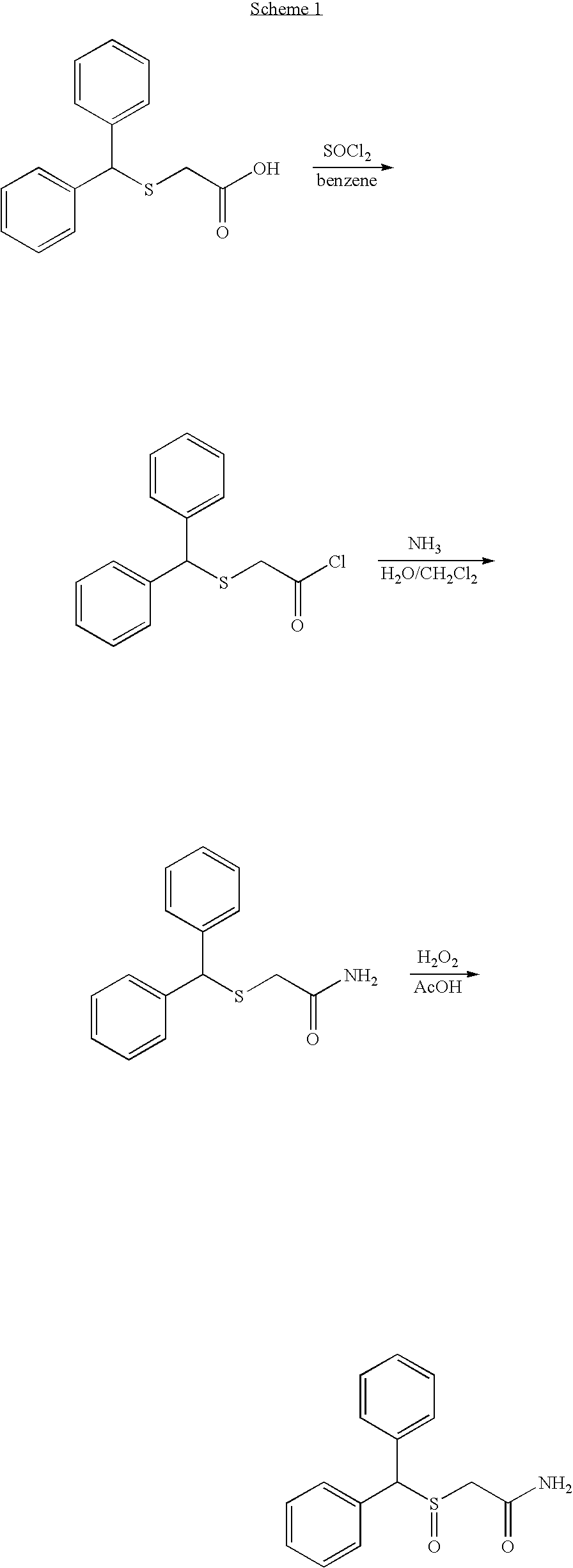

Modafinil synthesis process

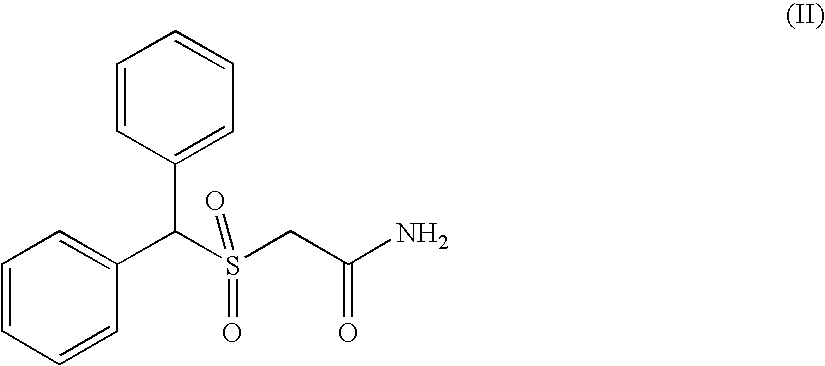

a technology of modafinil and synthesis process, which is applied in the field of synthesis process of modafinil, can solve the problems of difficult control, sulphone by-product (ii) which is difficult to separate from modafinil, and the preparation process, however, has drawbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

1-Liter Scale Procedure

[0107]A 1-liter reactor of type SIMULAR (Hazard Evaluation Laboratory, HEL) equipped with an impeller stirrer and a gas introduction tube was charged with 150 g of DMSAM, 450 ml of methanol and 33 mL of water. The suspension was stirred at 100 rpm and 20° C. for 10 min and then heated to 35° C. to dissolve the solids. The solution was subsequently stirred at 200 rpm for 10 min, then cooled to 25° C. and stirred at 350 rpm and at this temperature for 20 min.

[0108]46.8 g of ammonia were then introduced over 4.5 h at 25° C.

[0109]The reaction medium was left in contact for 10 h at 25° C. with stirring at 350 rpm before finally being cooled to −10° C. and then filtered over a frit of porosity 3.

[0110]The moist product was then dried under vacuum at 45° C.

[0111]Yield=89%, median=34.1 μm.

examples 2 to 5

Effect of temperature and Stirring Speed on Granulometry

example 2

Standard (Zero-Point) Experiment and Reproducibility

[0112]Conditions of standard experiment were the same as those of example 1.

[0113]The point at which the ammonia was injected, the jacket temperature, the cooling rate and the contact time at −10° C. were maintained constant during the various experiments, since these parameters had little or no influence on controlling the granulometry of the modafinil synthesized.

[0114]A standard experiment was desired in order to obtain a final granulometric median which was situated in the range 15-45 μm and thus to constitute a zero point of comparison for the subsequent experiments.

[0115]This search then culminates in the following conditions:[0116]reaction temperature T=25° C.,[0117]stirring speed SS=350 rpm,[0118]ammonia introduction time t=4.5 h.

[0119]Under these conditions the granulometric median obtained, G, was 34 μm.

[0120]This standard experiment was then repeated in order to assess its reproducibility: that was, three experiments con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com