Fully clamped coupled inductors in power conversion circuits

a technology of power conversion circuit and inductor, which is applied in the direction of dc circuit to reduce harmonics/ripples, electric variable regulation, instruments, etc., can solve the problems of increasing the leakage inductance in these circuits, reducing reducing the size and cost of power converter circuits. , to achieve the effect of improving the electromagnetic compatibility reducing the size and cost of power converter circuits,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

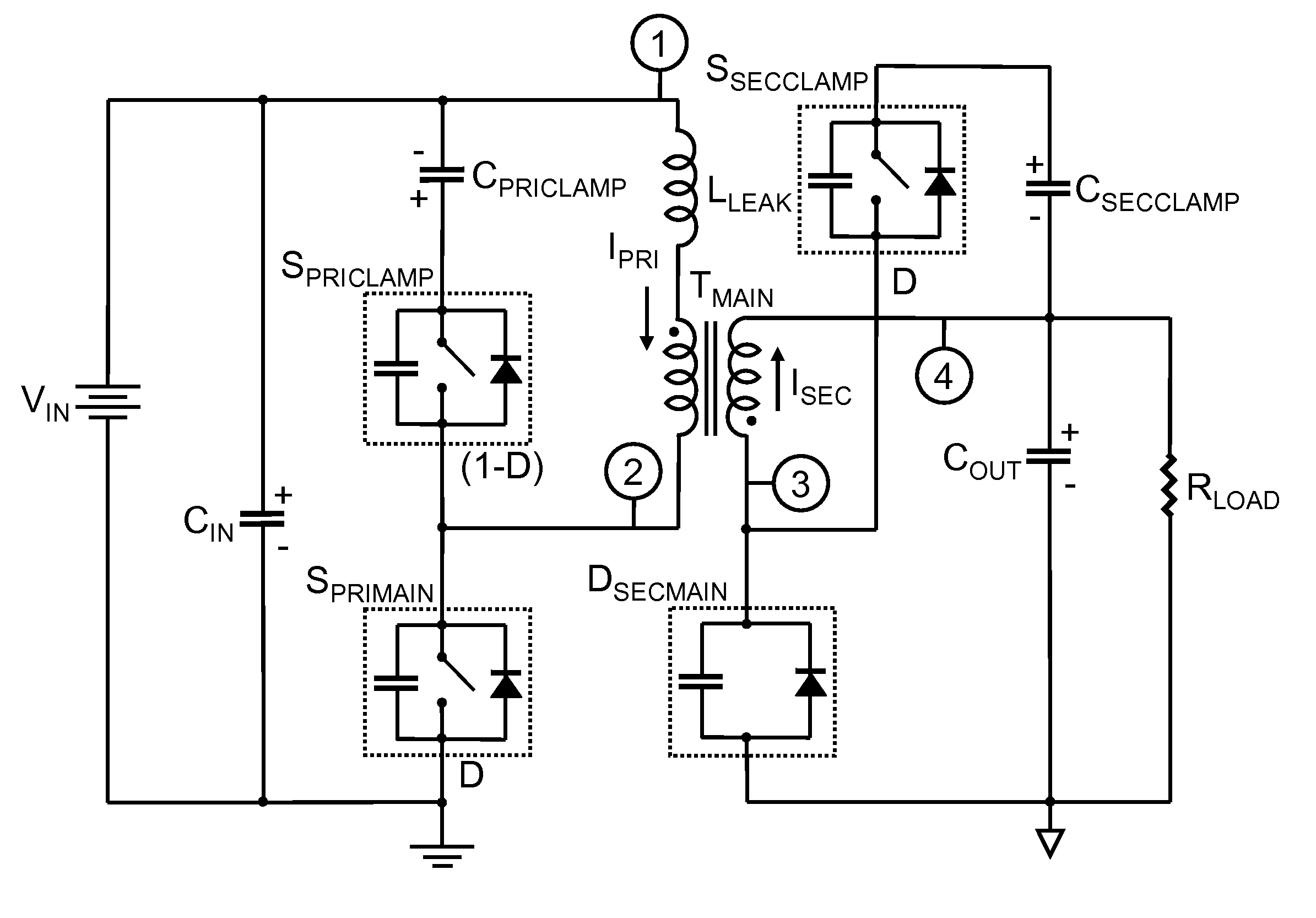

[0076]FIG. 8 illustrates the FIG. 3 circuit with the addition of an improvement, which is the subject of this invention. The improvement consists of an active clamp network comprising an active clamp switch SSECCLAMP and a capacitor CSECCLAMP.

[0077]In FIG. 8 a voltage source VIN has a first terminal connected to a first terminal of an input capacitor CIN, to a first terminal of a clamp capacitor CPRICLAMP, and to a first terminal of a primary winding of a flyback transformer TMAIN. A second terminal of the voltage source VIN is connected to a second terminal of the input capacitor CIN and to a first terminal of a switch SPRIMAIN. A second terminal of the switch SPRIMAIN is connected to a first terminal of a switch SPRICLAMP and to a second terminal of the primary winding of the transformer TMAIN. FIG. 8 illustrates a leakage inductance LLEAK connected in series with the primary winding of the transformer TMAIN, but it should be understood that LLEAK is an inherent part of TMAIN and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com