Soft-start/stop sump pump controller

a sump pump controller and soft-start technology, applied in the direction of machines/engines, positive-displacement liquid engines, dynamo-electric converter control, etc., can solve the problems of affecting the operation of the sump pump, and affecting the operation of the pump. , to achieve the effect of reducing the stress on the motor bearings, reducing the inrush start up current, and reducing the stress on the start up impa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

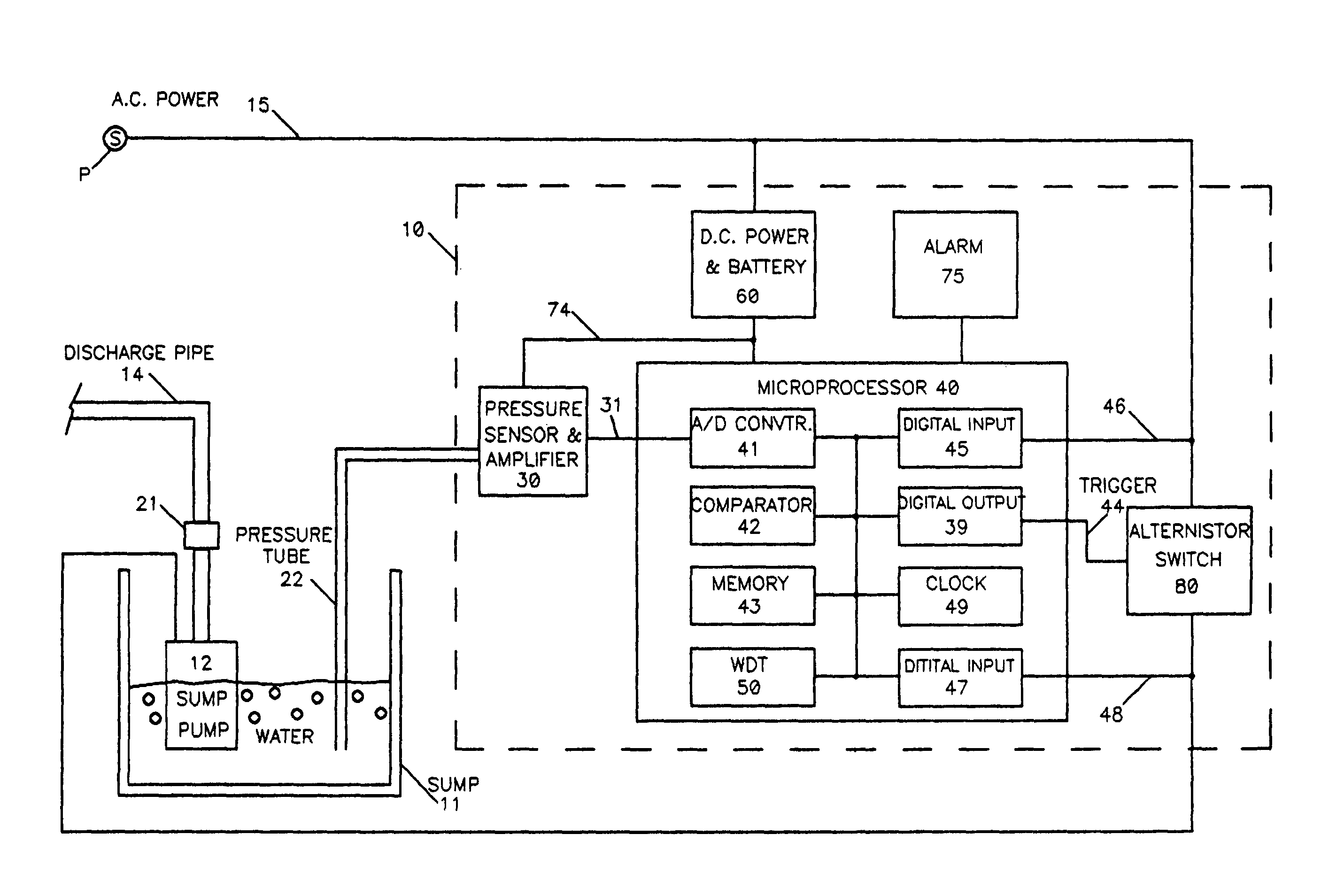

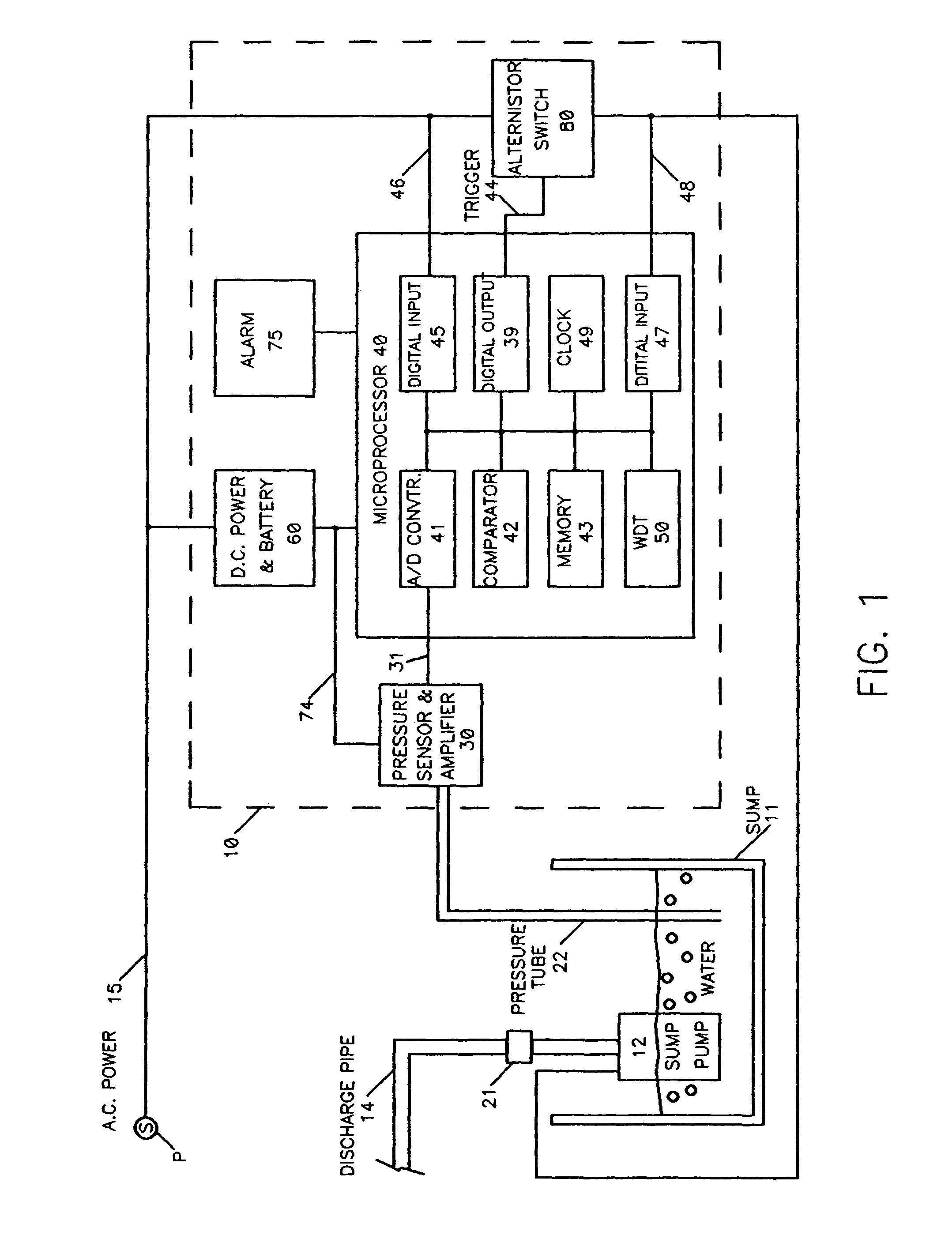

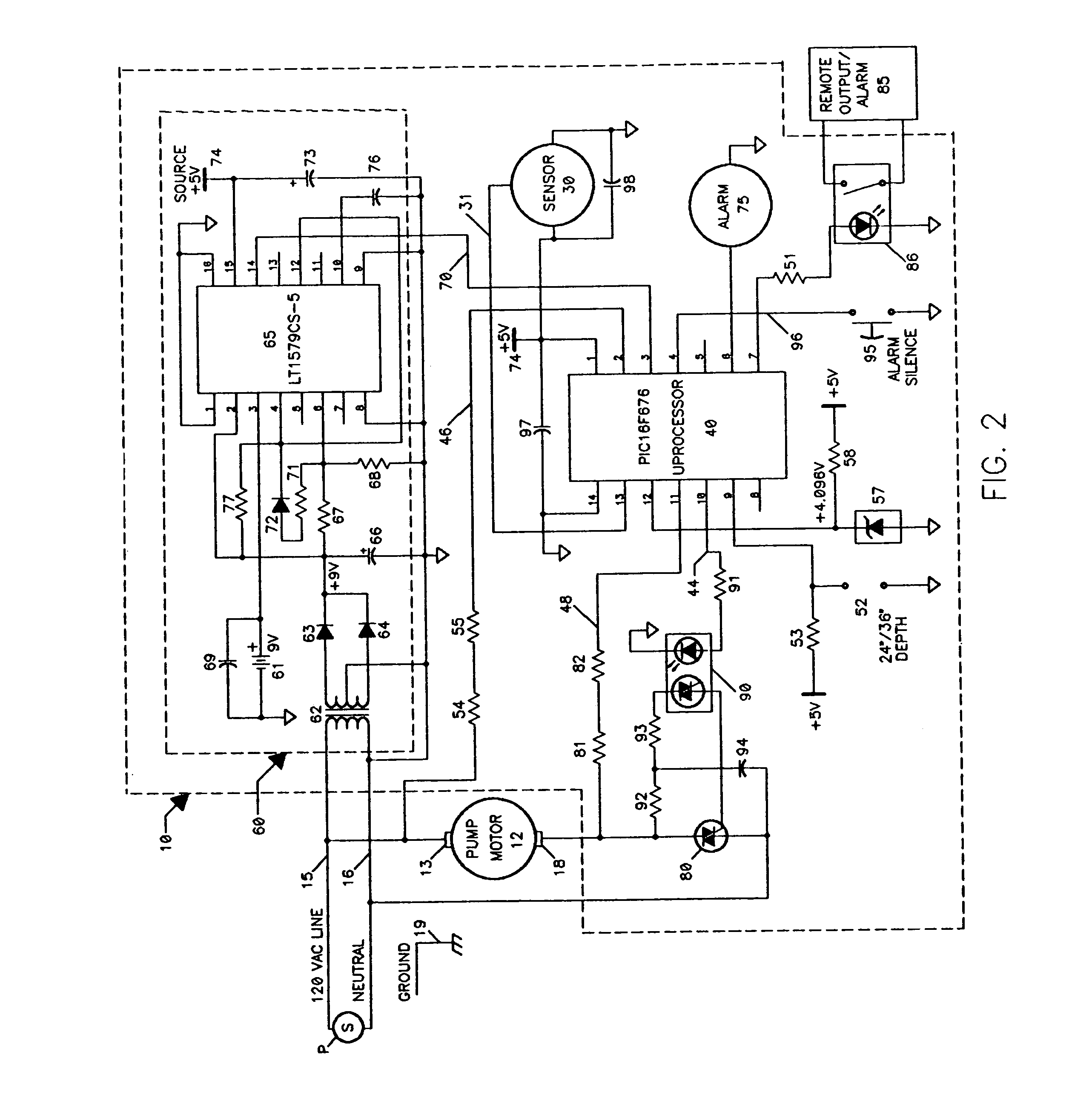

[0029]Referring to FIGS. 1 and 2, a controller 10 is connected to a sump pump 12 having contacts 13, 18 positioned within a sump pit 11. The sump pump 12 may be a submersible pump as depicted, or an upright pedestal pump of the type commonly known in the art, and is connected to a discharge pipe 14 through which water is discharged from a basement. Positioned along the discharge pipe 14 is a one way check valve 21 that prevents water in the discharge pipe 14 from flowing backwards into the sump pit 11 after the sump pump 12 has been turned off. Contained within controller 10 is a piezoresistive gauge pressure sensor 30.

[0030]Extending into the sump pit 11 and below the level of the water 20 is one end of a pressure tube 22 the other end of which is connected to the piezoresistive gauge pressure sensor 30 in the controller 10. The piezoresistive gauge pressure sensor 30 measures the pressure within the tube 22 that is greater than one atmosphere of air pressure and produces an output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com