Electric potential sensor

a potential sensor and electric current technology, applied in the field of electric potential sensors, can solve the problems of inability to accurately measure signals, inhibit or prevent accurate signal measurement, and high input impedance of electrical circuits with very high input impedance, etc., and achieve the effect of non-invasive and high-precision signal measuremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

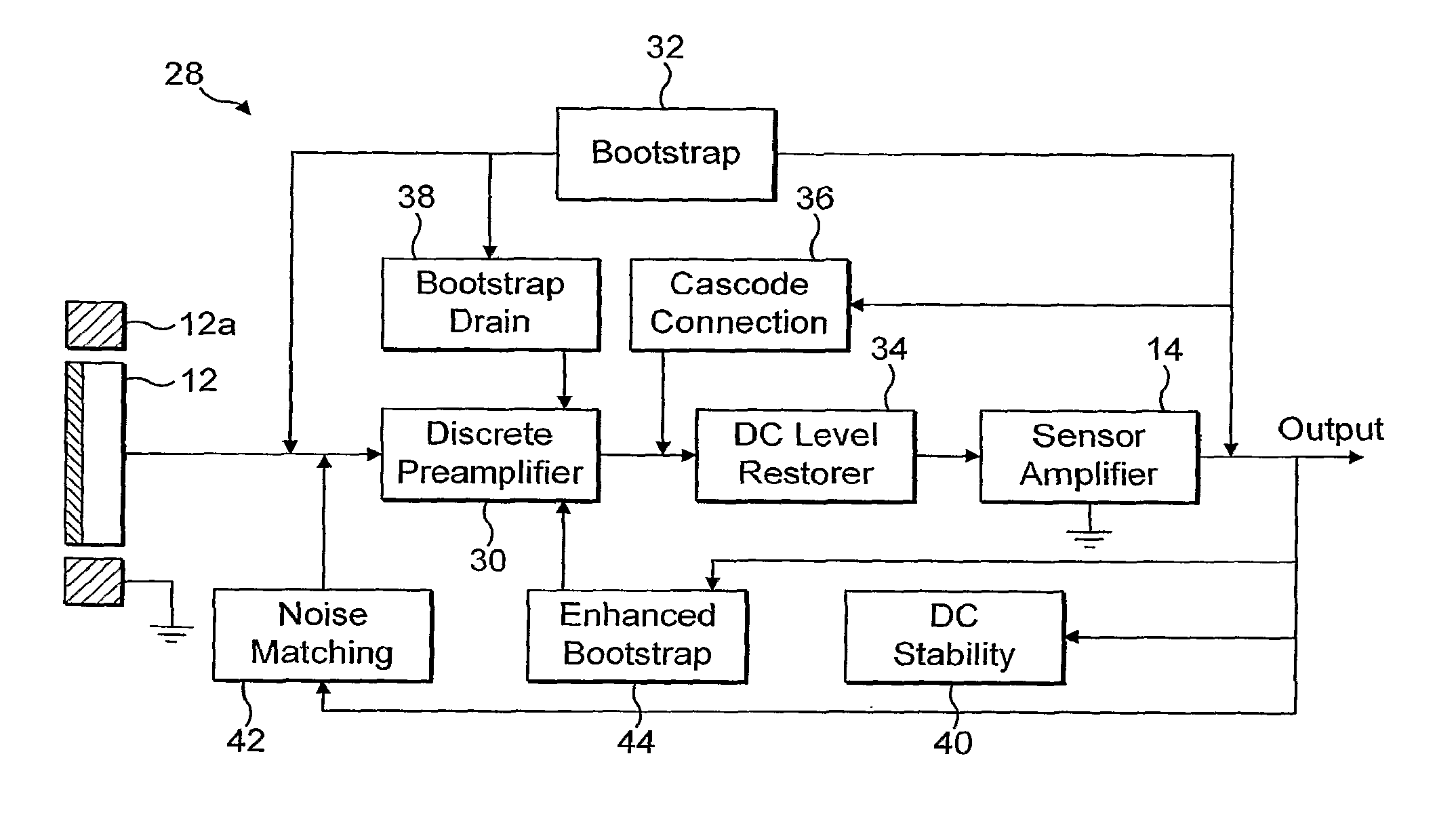

[0035]Referring to FIG. 1, an electrodynamic sensor as disclosed in International Patent Application No. WO 03 / 048789 will first be described.

[0036]As shown in FIG. 1, an eletrodynamic sensor 10 according International Patent Application number WO 03 / 048789 comprises a detection electrode 12 connected to the non-inverting input of a sensor amplifier 14. In use, the detection electrode 12 supplies a measurement signal to the sensor amplifier 14, whose output supplies an amplified detection signal as output.

[0037]The detection electrode 12 includes an electrode disc 16 mounted on a conductive stem 18, the electrode disc 16 comprising a surface oxide layer 20 on a substrate 22. The sensor amplifier 14 has a fixed input resistance 24, connected between the electrode 12 and the non-inverting input of the amplifier 14, to provide a steady input bias current to the amplifier 14. In practice, the input resistor 24 will generally have a high resistance of the order of 100 GΩs or greater. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com