Heat conductor device and method of forming a heat conductor device

a heat conductor and heat conductor technology, applied in the direction of cooling/ventilation/heating modifications, semiconductor/solid-state device details, and modifications by conduction heat transfer, can solve the problems of limiting radiation, limiting the size of a possible current loop, and reducing the effective electrical conductivity of the heat conductor device. , to achieve the effect of efficient formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

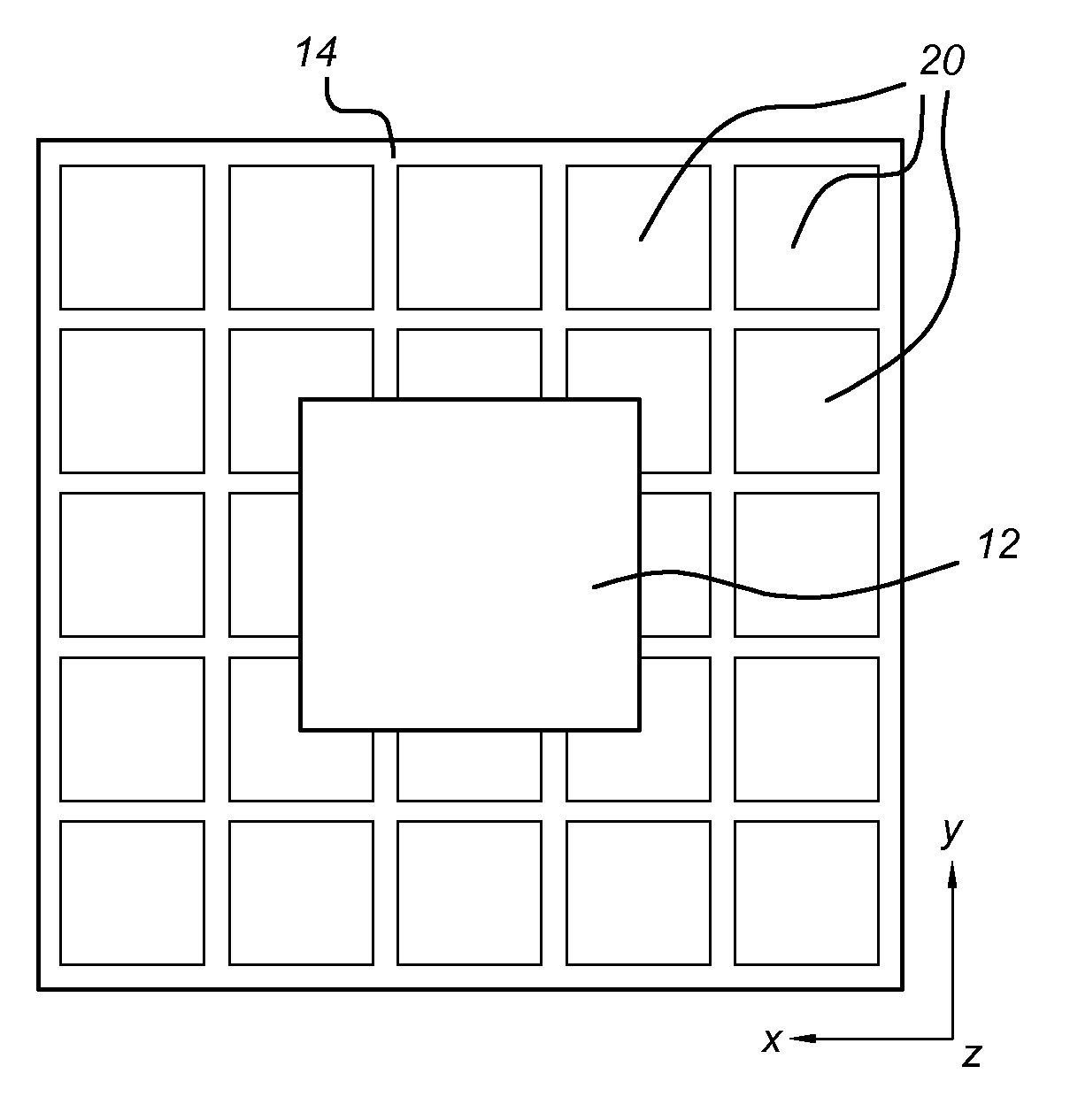

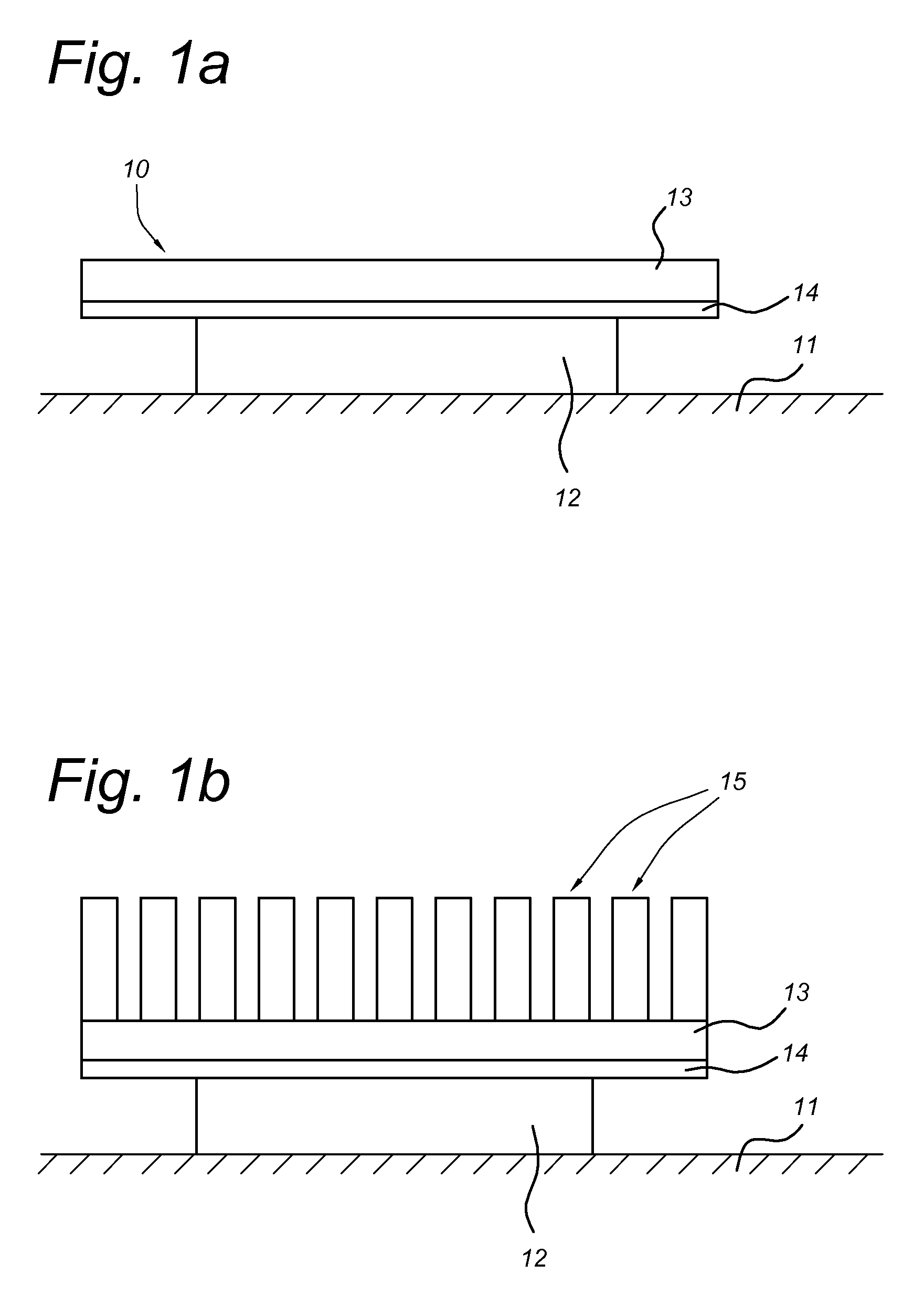

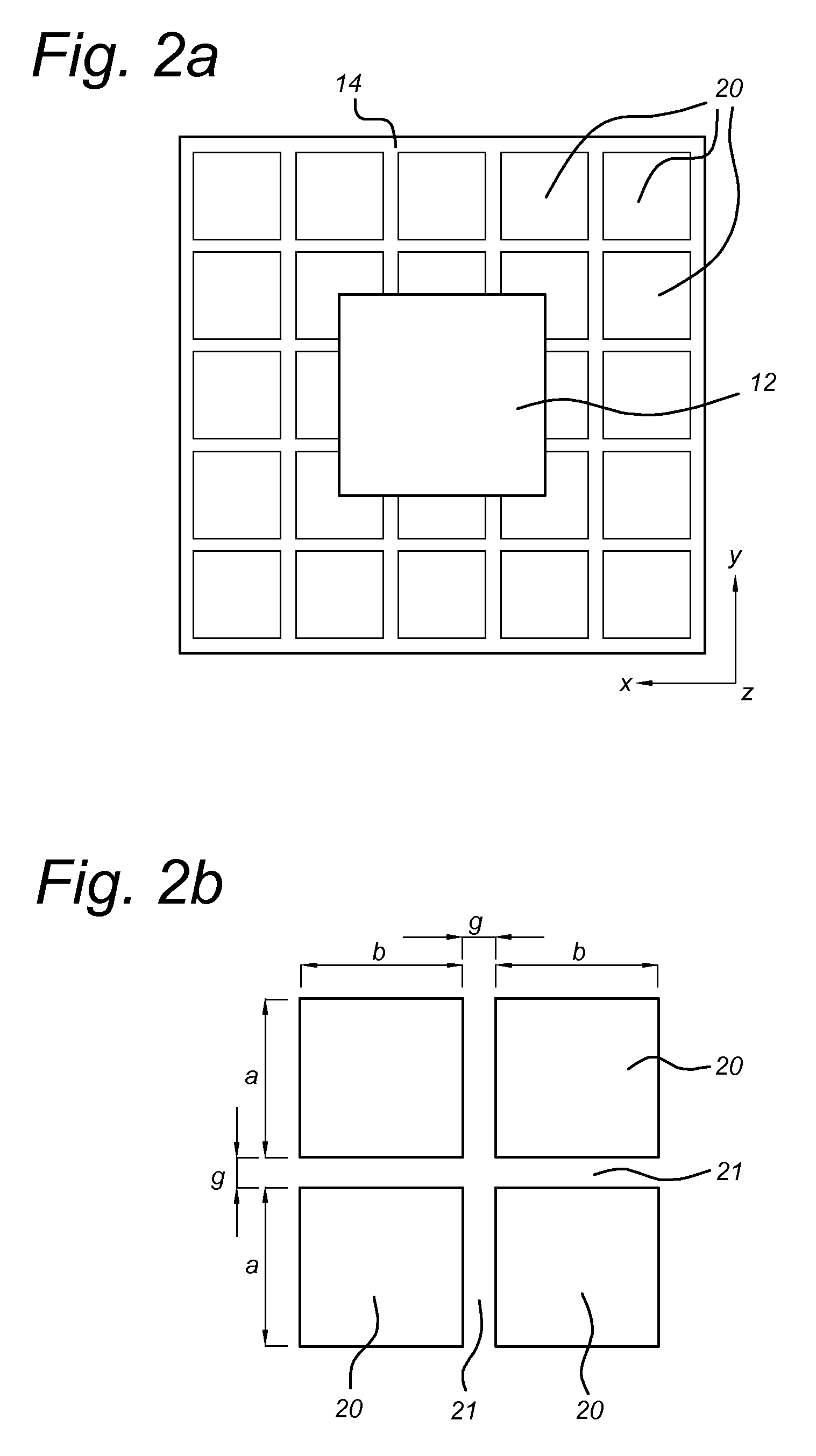

[0040]FIG. 1a schematically shows a heat conductor device 10 provided in thermal contact with an electrical component 12, in the present example an integrated circuit (IC) 12. The heat conductor device 10 comprises a body 13 made of plastic. Plastic advantageously has an essentially zero electrical conductivity, and thus does not give rise to the problems of radiating electromagnetic radiation if the plastic is provided on top of a high-frequency IC. Instead of plastic, any other material having a sufficiently low electrical conductivity can be used. A typical thickness of the body is between 0.5 and 5 mm, for example 1.5 mm. The body 13 is provided with a heat spreader 14 which will now be discussed in more detail in reference to FIGS. 2a and 2b. In the example of FIG. 1a, the heat spreader is located between the IC 12 and the body 13. In an alternative configuration, the heat spreader may be provided on top of the body 13, not facing the IC 12.

[0041]FIG. 1b shows a further alterna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com