Contamination control of gaseous emissions by corona-discharge generation of plasma

a technology of corona discharge and plasma, which is applied in the direction of lighting and heating apparatus, combustion types, separation processes, etc., can solve the problems of relatively expensive plasma generation by corona discharge process, and achieve the effect of reducing and less costly power consumption, reducing the required electrical energy consumption, and effected more efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

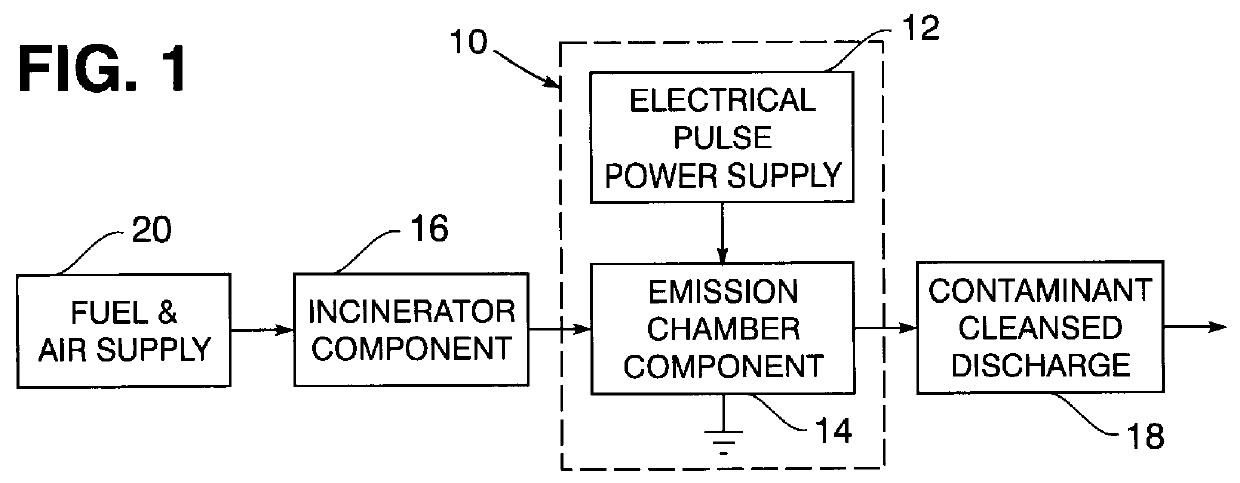

Referring now to the drawing in detail, FIG. 1 diagrams a corona discharge control system generally referred to by reference numeral 10, having an electrical pulse power supply 12 operationally connected to an emission chamber component 14. Pursuant to the present invention, the gas emission from an incinerator component 16 embodied in or associated with equipment or devices is decontaminated during passage through the emission chamber component 14 of the system 10 to provide a contaminant cleansed discharge 18 as diagrammed in FIG. 1. Such discharge 18 is in the form of a clean air emission where fuel and air from a supply 20 undergoes burning in the incinerator component 16.

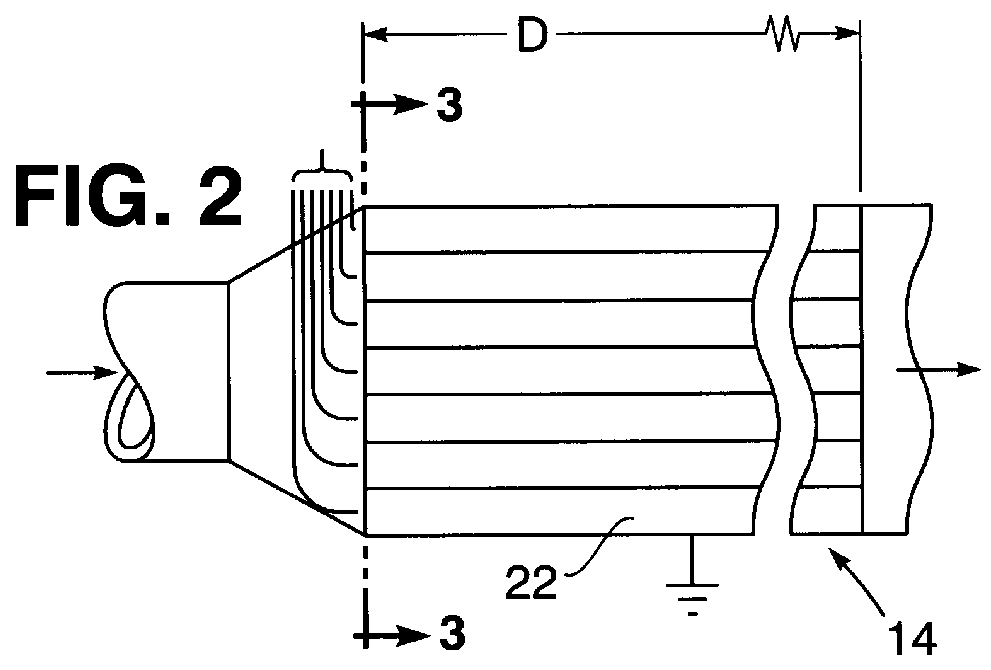

A gas emission from the incinerator component 16 maintained at a relatively high temperature (T) passes through the emission chamber component 14 having a flow passage length (D) as denoted in FIG. 2. As shown in FIG. 3, the flow passage through chamber component 14 is enclosed within an electrically grounded h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com